An automatic control method for reverse sewing of sewing machine

A sewing machine and automatic technology, applied in sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of fabric waste and reduce sewing efficiency, and achieve the effect of avoiding fabric waste and improving sewing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

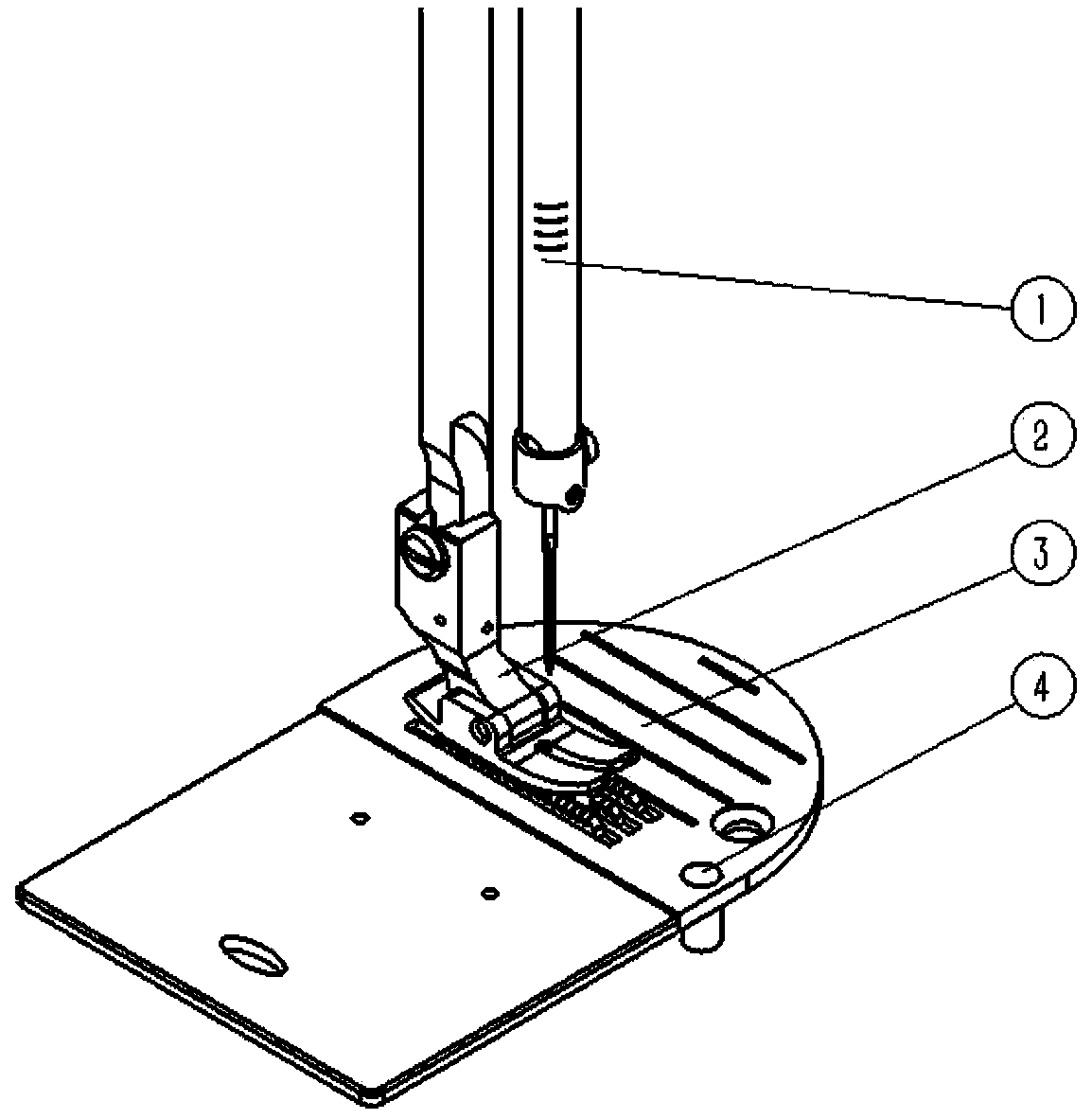

[0023] The following are specific embodiments of the present invention and in conjunction with the attached figure 1 , to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

[0024] An automatic control method for reverse sewing of a sewing machine, comprising the following steps:

[0025] (1) When sewing starts, the sensor 4 installed near the presser foot 2 senses whether there is any fabric passing through the sensor 4 and put between the presser foot 3 and the needle plate 2, and the controller reads the state of the sensor 4 to judge whether there is any cloth exists;

[0026] If there is no fabric, the sewing machine will not work;

[0027] If there is fabric, one control method is that the sewing operator sets the number of needles that the fabric advances before the automatic reverse sewing action according to the program. After the fabric advances according to the set needle number, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com