A kind of aqueous polyacrylate emulsion and preparation method thereof

A technology of polyacrylate emulsion and ethyl acrylate, applied in coating and other directions, can solve problems such as affecting the normal progress of polymerization reaction, increasing the problems of compounding and application functions, and insufficient stability of mechanical and calcium particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

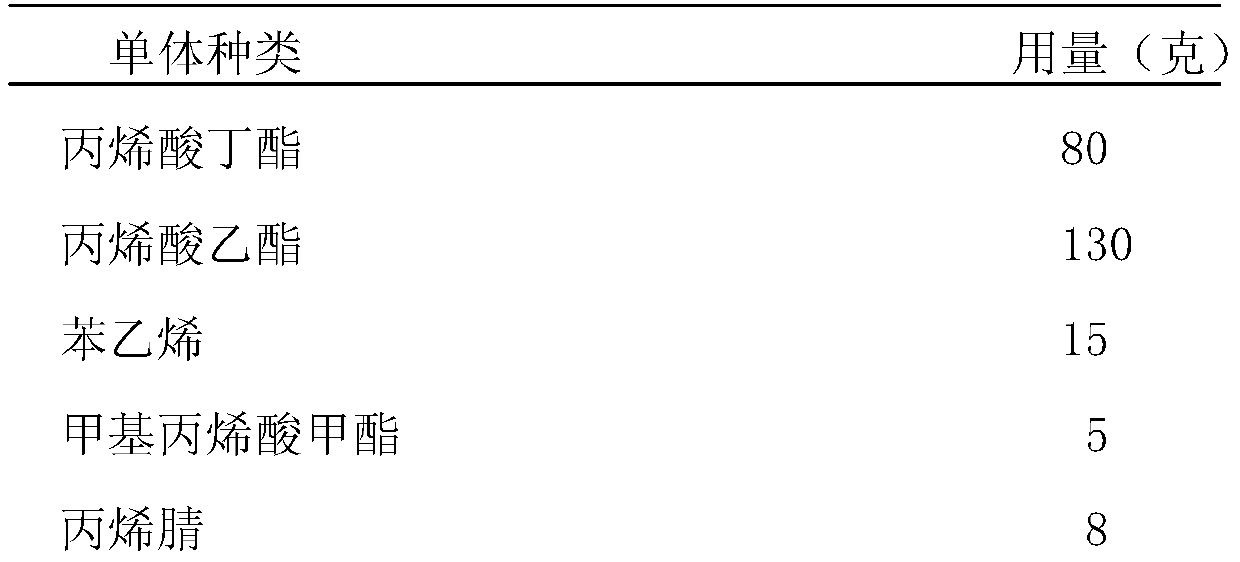

[0023] Lotion ingredients:

[0024]

[0025]

[0026] Preparation method: after dissolving 98% alkyl alcohol polyoxyethylene ammonium sulfate and dibutyl sulfosuccinate sodium salt, isomeric alcohol polyoxyethylene ether (8-12EO) in 60% deionized water, under stirring Add butyl acrylate, ethyl acrylate, styrene, methyl methacrylate, acrylonitrile, acrylic acid, N-methylol acrylamide, sodium allyloxy hydroxypropyl sulfonate, stir and emulsify for 10-20 minutes, then Emulsify and disperse with a high-shear dispersing emulsifier for 10 minutes to obtain a uniform and stable pre-emulsion.

[0027] Add sodium bicarbonate and a small amount of remaining compound emulsifier, and most of the remaining deionized water into a four-necked flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, and stir, then take 2.5% of the pre-emulsion Add to the reaction bottle; heat and stir, add redox initiator hydrosulfite, ferrous sulfate and 15% ammonium pe...

Embodiment 2

[0029] Lotion ingredients:

[0030]

[0031] Preparation method: After dissolving sodium alkyl diphenyl ether disulfonate and isomeric secondary alcohol polyoxyethylene ether (8-12EO) in 1 / 2 deionized water, add isooctyl acrylate, ethyl acrylate, Styrene, methyl methacrylate, acrylonitrile, itaconic acid, acrylamide, hydroxypropyl methacrylate, hydroxypropyl methacrylate, stirred and emulsified for 15 minutes, and then emulsified and dispersed by a high-shear dispersing emulsifier for 12 minutes , to obtain a uniform and stable pre-emulsion.

[0032] Sodium bicarbonate and most of the remaining deionized water are added to a four-necked flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer and stirred, then 2% pre-emulsion is added to the reaction flask; heated and stirred, Add redox initiator hydrosulfite, ferrous sulfate and 15% ammonium persulfate at a temperature of 25-30°C to initiate a polymerization reaction to obtain a seed emulsio...

Embodiment 3

[0034] Lotion ingredients:

[0035]

[0036] Preparation method: After dissolving 95% isomeric alcohol polyoxyethylene ether (40EO) and ethoxylated alkyl alcohol ether sulfosuccinic acid half ester disodium salt in 55% deionized water, add butyl acrylate under stirring Ester, ethyl acrylate, glycidyl methacrylate, methyl methacrylate, acrylonitrile, acrylic acid, acrylamide, sodium hydroxypropyl methacrylate, stirred and emulsified for 20 minutes, and then emulsified by a high-shear dispersing emulsifier Disperse for 10 minutes to obtain a uniform and stable pre-emulsion.

[0037] Add sodium bicarbonate and a small amount of remaining compound emulsifier, and most of the remaining deionized water into a four-necked flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer, and stir, then take 3% of the pre-emulsion Add to the reaction bottle; heat and stir, add redox initiator sodium powder, ferrous sulfate and 10% ammonium persulfate at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com