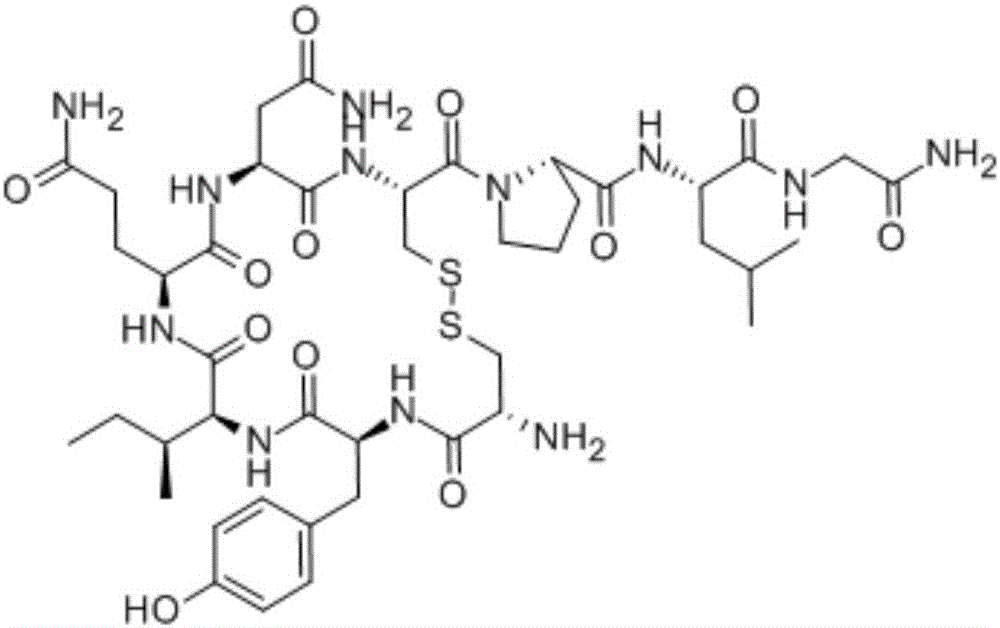

Purification method of oxytocin

A purification method, the technology of oxytocin, applied in the chemical industry, can solve the problems of unfavorable large-scale production process, environmental pollution, and residue, etc., and achieve the effects of low toxicity, reduced production cost, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The refining purification method (1) of embodiment 1 oxytocin

[0025] 1. Concentration

[0026] Take 1 kg of oxytocin solution (2% by mass) and distill under reduced pressure at 45°C to 20% by mass, with a volume of 90ml.

[0027] 2. Crystallization

[0028] Add 90ml of the concentrated solution prepared in the first step to 120ml of ethanol, stir for 30min at 25-30°C, keep stirring in an ice bath at a temperature of -5-0°C for 18h, and a large amount of solids precipitate out.

[0029] 3. Filter and dry

[0030] After filtration, the solid was washed with 15 ml of ethanol, and the obtained solid was vacuum-dried at 40° C. for 5 hours to obtain 18.8 g of the product, with a total yield of 94%. The purity of the purified oxytocin was determined to be 97.01% by HPLC.

Embodiment 2

[0031] The refining purification method (2) of embodiment 2 oxytocin

[0032] 1. Concentration

[0033] Take 1 kg of oxytocin solution (2% by mass percentage) and distill it under reduced pressure at 40-45° C. to 20% by mass, with a volume of 90 ml.

[0034] 2. Crystallization

[0035] Add 90ml of the concentrated solution prepared in the first step to 90ml of isopropanol, stir for 30min at 25-30°C, keep stirring in an ice bath at a temperature of -10-0°C for 18h, and a large amount of solids precipitate out.

[0036] 3. Filter and dry

[0037] After filtering, the solid was washed with 15 ml of isopropanol, and the obtained solid was vacuum-dried at 45°C for 5 hours to obtain 15.42 g of the product, with a total yield of 77.1%. The content of purified oxytocin was 96.2% as determined by HPLC.

Embodiment 3

[0038] The refining purification method (3) of embodiment 3 oxytocin

[0039] 1. Concentration

[0040] Take 1kg of oxytocin solution (2% by mass) and distill it under reduced pressure at 40-45°C to 24% by mass, with a volume of 84ml.

[0041] 2. Crystallization

[0042] Add 84ml of the concentrated solution prepared in the first step to 90ml of isopropanol, stir for 30min at 25-30°C, keep stirring in an ice bath at a temperature of -10-0°C for 18h, and a large amount of solids precipitate out.

[0043] 3. Filter and dry

[0044] After filtering, the solid was washed with 15 ml of isopropanol, and the obtained solid was vacuum-dried at 45° C. for 5 hours to obtain 14.8 g of the product, with a total yield of 74%. HPLC content 96.4%.

[0045] It can be seen from the above examples that the process of the present invention is suitable for synthesis under laboratory conditions, the reaction raw materials and solvents are easy to get, there are no harsh reaction conditions, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com