2-methylimidazole zinc salt as well as preparation method and application thereof

A technology of methyl imidazole zinc and methyl imidazole, which is applied in the field of 2-methyl imidazole zinc salt and its preparation, can solve the problems of affecting the thermal stability of PVC products, increase economic cost, use restrictions and the like, and achieve solvent recycling. , the effect of reducing coloration and reducing acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Get 23.79g (molecular weight 297.49, 80mmol) zinc nitrate hexahydrate and 105.20g deionized water and join in the reaction vessel, 13.14g (molecular weight 82.10, 160mmol) 2-methylimidazole is completely dissolved in 164.40g (mass fraction 25-28%) ammonia water was added to the above-mentioned reactor, the temperature was raised to 20° C., centrifuged after reacting for 10 minutes, washed with deionized water until neutral, and dried overnight at 65° C. to obtain white solid 2-methylimidazole zinc salt;

[0024] (2) 9.6g of calcium stearate, 1.68g of zinc stearate and 0.72g of 2-methylimidazole zinc salt were compounded to obtain a calcium-zinc composite thermal stabilizer.

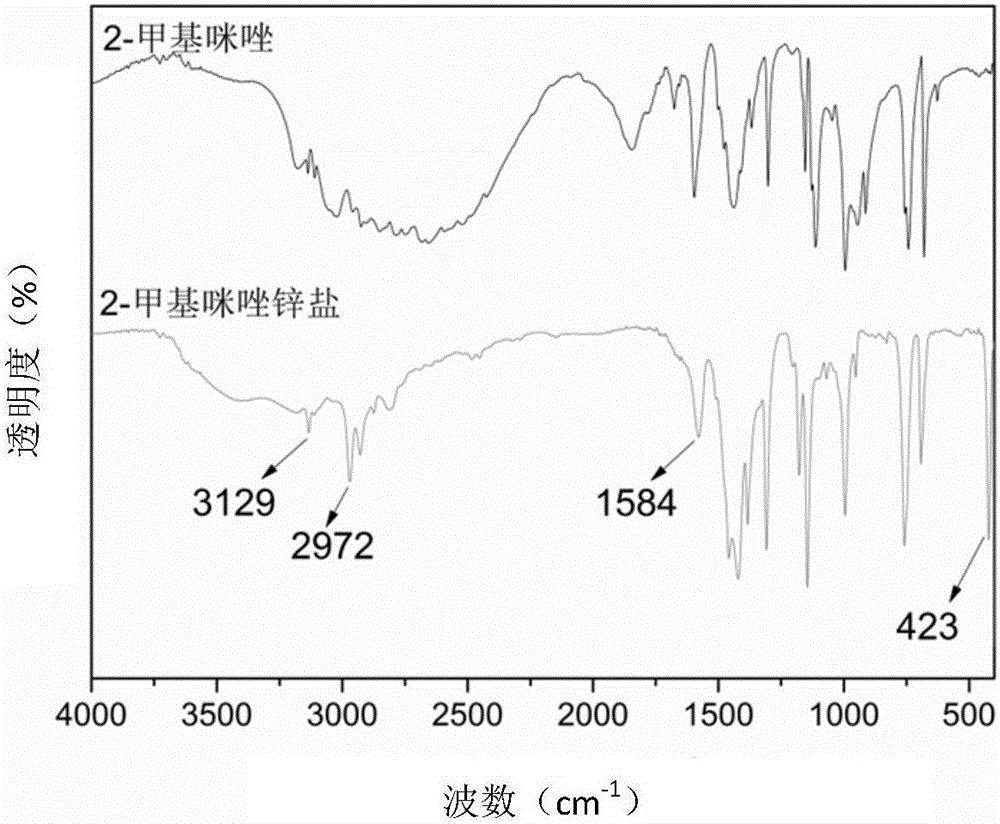

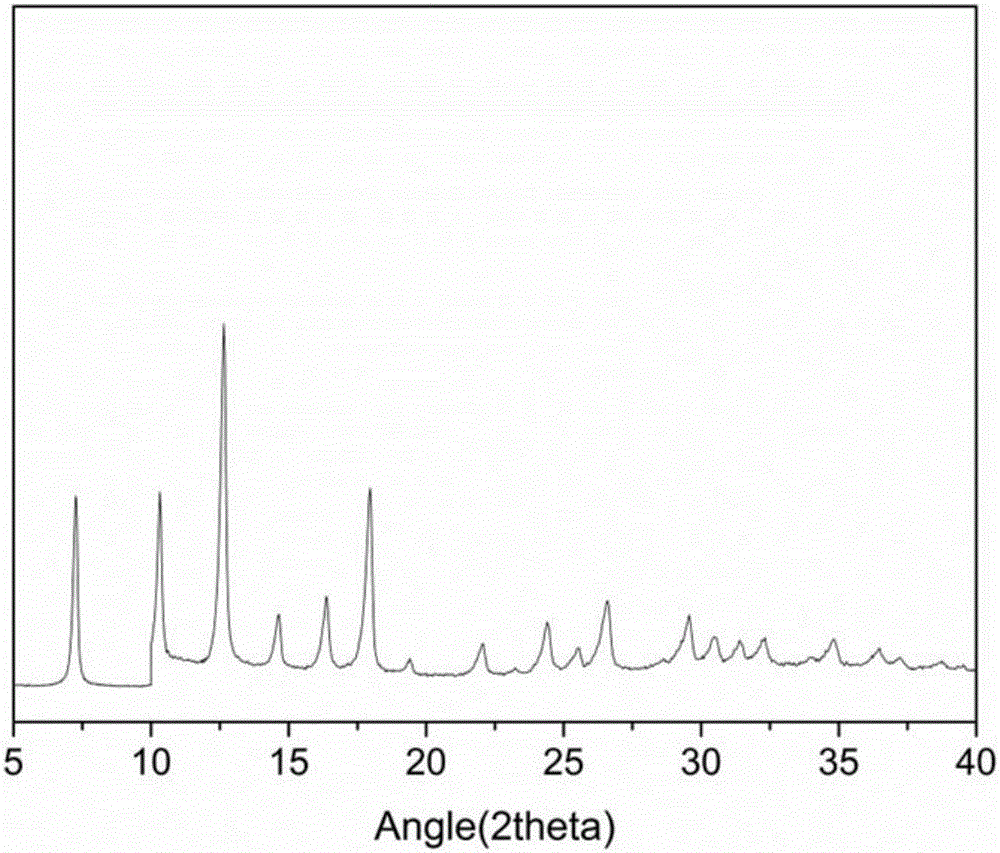

[0025] The infrared spectrogram of the 2-methylimidazole zinc salt prepared in this embodiment is shown in figure 1 . figure 1 Medium 3129 and 2972cm -1 The C–H stretching vibration absorption peaks of benzene ring and imidazole appear at 1584cm -1 C=N stretching vibration absorption peak ap...

Embodiment 2

[0027] (1) Get 23.79g (molecular weight 297.49, 80mmol) zinc nitrate hexahydrate and 121.70g deionized water and join in the reaction vessel, 13.14g (molecular weight 82.10, 160mmol) 2-methylimidazole is completely dissolved in 128.30g (mass fraction 25-28%) ammonia water was added to the above-mentioned reactor, the temperature was raised to 20° C., centrifuged after reacting for 30 minutes, washed with deionized water until neutral, and dried overnight at 65° C. to obtain white solid 2-methylimidazole zinc salt;

[0028] (2) 9.6g of calcium stearate, 0.72g of zinc stearate and 1.68g of 2-methylimidazole zinc salt were compounded to obtain a calcium-zinc composite thermal stabilizer.

Embodiment 3

[0030] (1) Get 23.79g (molecular weight 297.49, 80mmol) zinc nitrate hexahydrate and 105.20g deionized water and join in the reaction vessel, 13.14g (molecular weight 82.10, 160mmol) 2-methylimidazole is completely dissolved in 164.40g (mass fraction 25-28%) ammonia water was added to the above reactor, the temperature was raised to 20°C, centrifuged after reacting for 60 minutes, washed with deionized water until neutral, and dried overnight at 65°C to obtain white solid 2-methylimidazole zinc salt;

[0031] (2) 9.6g of calcium stearate, 1.20g of zinc stearate and 1.20g of 2-methylimidazole zinc salt were compounded to obtain a calcium-zinc composite thermal stabilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com