Asphalt mixture blending method

A technology of asphalt mixture and asphalt, which is applied in the field of asphalt mixture mixing methods, can solve the problems of uneven thickness of asphalt oil film and affect the performance of asphalt mixture, and achieve the effect of improving economic benefits of enterprises, reducing waste and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

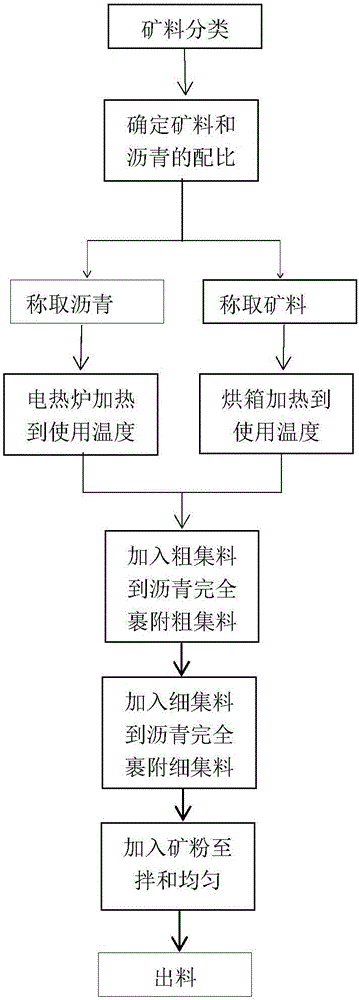

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a mixing method for asphalt mixture, wherein: the ratio of mineral aggregates adopts the requirements of AC-16 mineral aggregate gradation, the asphalt used is SBS modified asphalt, and the quality of the asphalt is 4.5% of the mass of mineral aggregates. The process includes the following steps:

[0055] 1. Preparation stage:

[0056] Prepare the following instruments and materials: ore; SBS modified asphalt; boundary sieve; an electronic scale with a sensitivity of 0.1g and a range of 10kg; a hand shovel; an iron plate.

[0057] 2. Determine the amount of mineral materials and asphalt:

[0058] (2.1) Classification of mineral materials: use the boundary screen to complete the screening of coarse aggregate, fine aggregate and mineral powder.

[0059] (2.2) Weighing of mineral material and asphalt: the total mass of mineral material to be mixed in this embodiment is 3600g, and the mass of asphalt is 3600g×4.5%=162g. The mass ratio of coarse a...

Embodiment 2

[0069] This embodiment provides an asphalt mixture mixing method, wherein: the ratio of mineral aggregate and asphalt adopts the AC-16 mineral aggregate grading requirements, the asphalt used is No. 90 base asphalt, and the asphalt content is 4.1%. The process includes the following steps:

[0070] 1. Preparation stage:

[0071] Prepare the following instruments and materials: Mineral material; No. 90 matrix pitch; boundary sieve; an electronic scale with a sensitivity of 0.1g and a measuring range of 10kg; a hand shovel; an iron plate.

[0072] 2. Determine the amount of mineral materials and asphalt:

[0073] (2.1) Classification of mineral materials: use the boundary screen to complete the screening of coarse aggregate, fine aggregate and mineral powder.

[0074] (2.2) Weighing of mineral material and asphalt: the total amount of asphalt mixture that needs to be mixed in this embodiment is 3600g, and the quality of asphalt is 3600g×4.1%=147.6g, according to the requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com