System for recycling hydrogen in production process of polycrystalline silicon

A production process and recovery system technology, applied in hydrogen/synthesis gas production, hydrogen separation, hydrogen separation using liquid contact, etc., can solve the problems of hydrogen compressor wear and damage, hydrogen compressor maintenance difficulties, etc., to avoid wear and damage, Effects of reducing hydrogen consumption and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

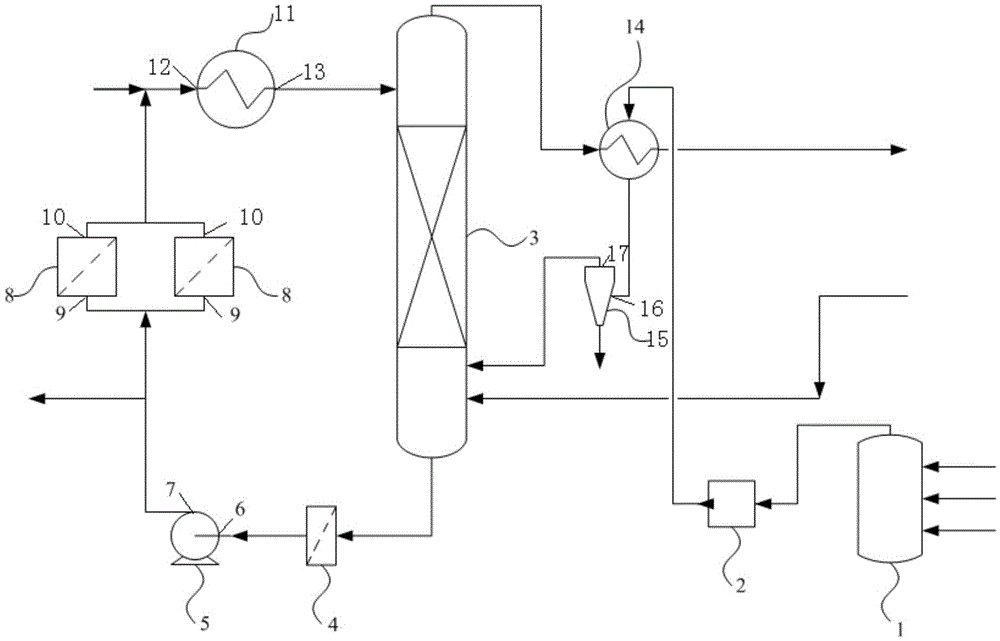

[0037] Such as figure 1 As shown, this embodiment provides a hydrogen recovery system in the polysilicon production process, including:

[0038] Oil-containing hydrogen buffer tank 1, used to store high boiling substance cracking gas, hydrogen protective gas for cold hydrogenation, hydrogen protective gas for recovery of reduction tail gas; high boiling substance cracking gas, hydrogen protective gas for cold hydrogenation, hydrogen protective gas for recovery of reduction tail gas Both are oil-containing hydrogen. The oil-containing hydrogen buffer tank 1 is equipped with a regulating valve, and the pressure of the oil-containing hydrogen buffer tank 1 is 50KPaG, and the pressure is released when it exceeds the system pressure.

[0039] A hydrogen compressor 2 is connected with the oil-containing hydrogen buffer tank 1, and the hydrogen compressor 2 is used for compressing and deoiling;

[0040]A hydrogen leaching tower 3 is connected with the hydrogen compressor 2, and the...

Embodiment 2

[0065] Use the hydrogen recovery system in the polysilicon production process in Example 1 to recover dusty hydrogen and oily hydrogen:

[0066] 1) Supplement fresh silicon tetrachloride into the hydrogen leaching tower, and establish the liquid level of the hydrogen leaching tower to reach 1000mm to ensure the safe start of the chlorosilane circulation pump;

[0067] 2) Start the chlorosilane circulation pump, put into use the chlorosilane cryocooler, and establish a chlorosilane circulation volume of 25m 3 / h, the system temperature is reduced to -20°C, and the liquid level is stabilized at 1700mm.

[0068] 3) Put into use the oil-containing hydrogen buffer tank, feed air into the system, and when the system pressure reaches 50KPaG, start the hydrogen compressor, supply gas to the hydrogen leaching tower and return to adjust the pressure of the oil-containing hydrogen buffer tank, and adjust the valve on the top of the hydrogen leaching tower Regulate the pressure of the hy...

Embodiment 3

[0073] Use the hydrogen recovery system in the polysilicon production process in Example 1 to recover dusty hydrogen and oily hydrogen:

[0074] 1) Supplement fresh chlorosilane (silicon tetrachloride: trichlorosilane volume ratio 4:1) into the hydrogen elution tower, and establish the liquid level of the hydrogen elution tower to reach 1000mm to ensure the safety of the chlorosilane circulating pump start up;

[0075] 2) Start the chlorosilane circulation pump, put into use the chlorosilane cryocooler, and establish a chlorosilane circulation volume of 20m 3 / h, the system temperature is reduced to -40°C, and the liquid level is stabilized at 1700mm.

[0076] 3) Put into use the oil-containing hydrogen buffer tank, feed air into the system, and when the system pressure reaches 30KPaG, start the hydrogen compressor, supply gas to the hydrogen leaching tower and return to adjust the pressure of the oil-containing hydrogen buffer tank, and adjust the valve on the top of the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com