Active pay-off tension control device and wire winding method thereof

A technology of pay-off tension and control device, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problems of wire stretching deformation, increased defective rate, and substandard product quality. Improved production efficiency, high production efficiency, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail:

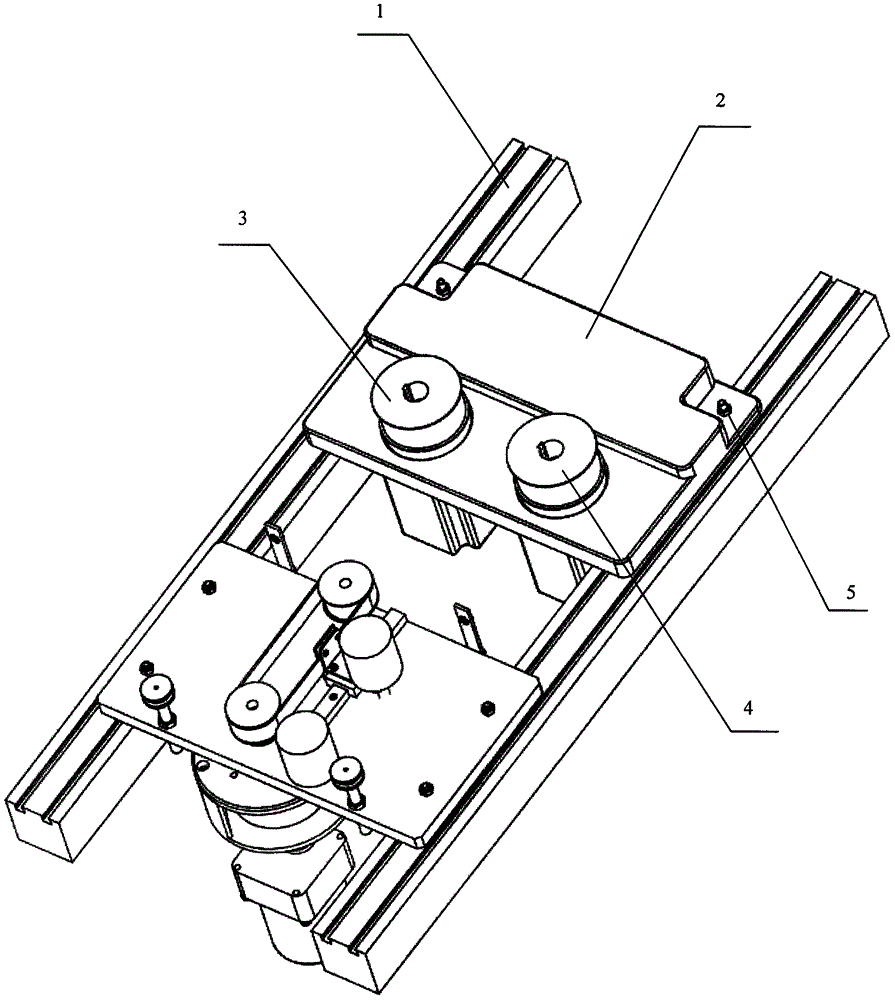

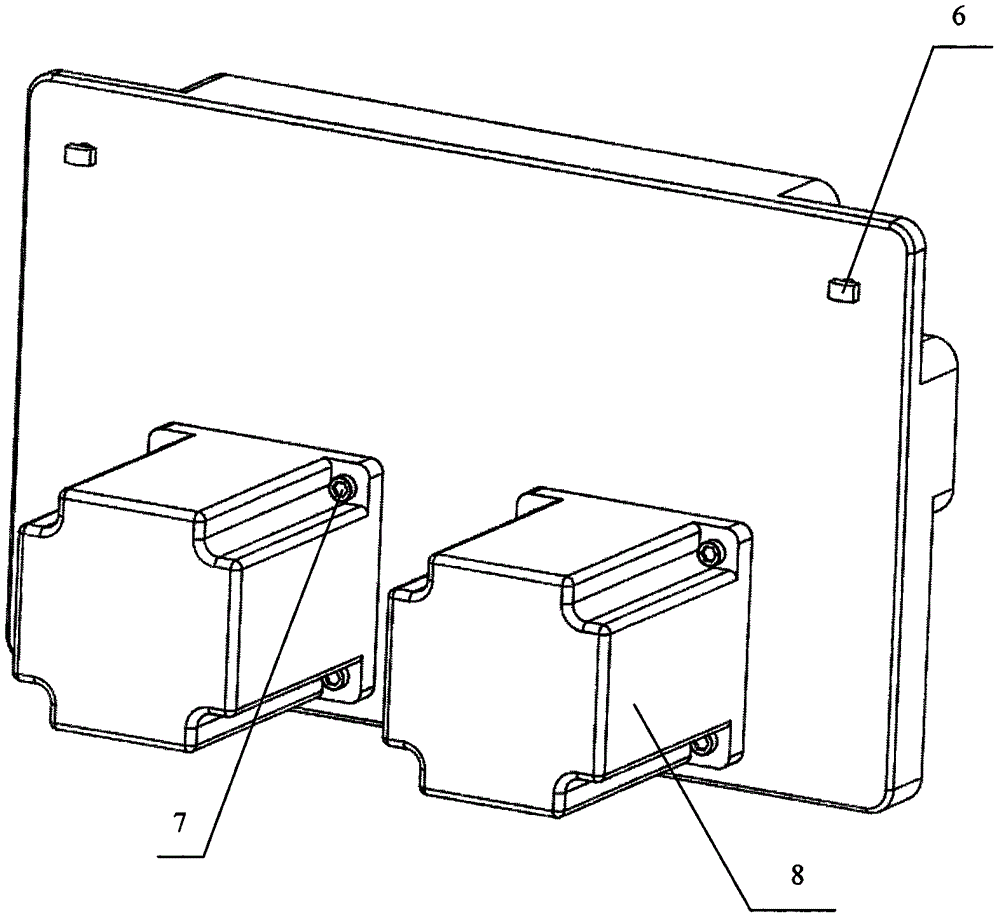

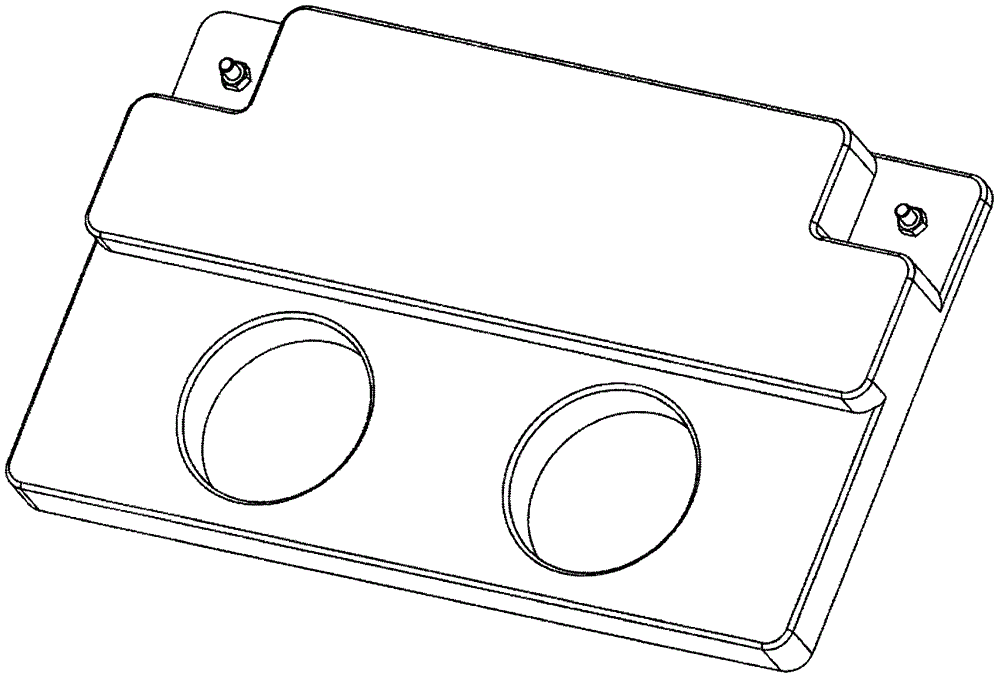

[0024] refer to Figure 1 to Figure 19 , an active pay-off tension control device provided by the present invention, such as figure 1 shown, including: figure 2 and image 3 motor board shown, Figure 4 bracket shown, Figure 5 Pay-off barrel shown, Image 6 Take-up barrel shown, Figure 7 and Figure 8 The tension feedback device shown, Figure 9 base plate shown, Figure 10 ceramic eye mounting plate shown, Figure 11 guide wheel shown, Figure 12 It is the fixed seat of the synchronous pulley shaft, Figure 13 , 14 and the floating structure shown in 15, Figure 16 mobile plate shown, Figure 17 fixed plate shown, Figure 18 floating roller shown, Figure 19 Fixed roller shown.

[0025] During use, the motor board 2 is fixed on the fixed frame 1 with bolts 6 and nuts 5 of the T-shaped slot. Similarly, the bottom plate 9 is fixed on the fixed frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com