Torsion beam structure of rear suspension

A technology of torsion beam and rear suspension, applied in the direction of suspension, interconnection system, transportation and packaging, etc., can solve the problem that the length of the lap joint is not easy to control, the strength of the beam is low, and the installation structure of the front rubber bushing is unfavorable for the vehicle to understeer. characteristics and other issues, to achieve the effects of reducing the risk of X-direction misalignment and Y-direction lap length discomfort, high fatigue durability safety factor, and wide platform modification extensibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The rear suspension torsion beam structure of the present invention will be further elaborated below in conjunction with specific embodiments, in order to make a more complete and clear description of the technical solution of the present invention.

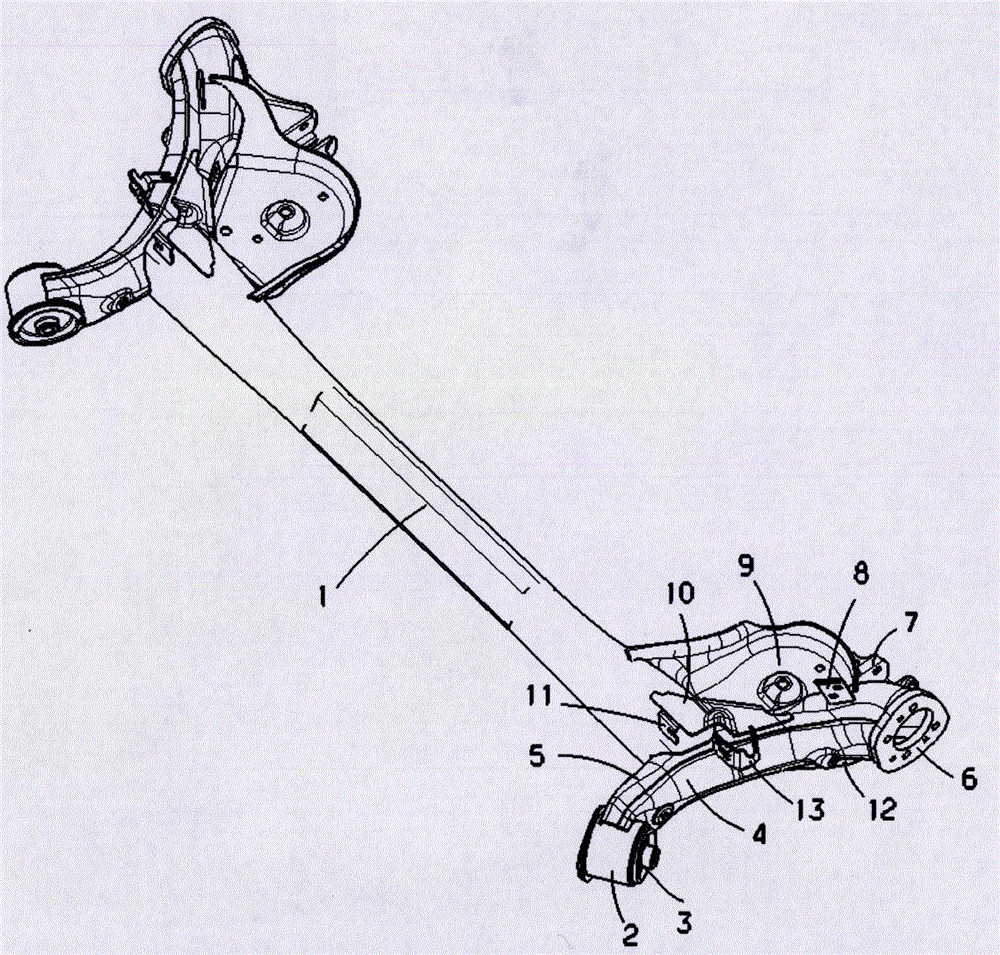

[0050] Such as figure 1 As shown, the rear suspension torsion beam of this embodiment includes a crossbeam 1, the two ends of the crossbeam are symmetrically provided with trailing arms, and the trailing arms are composed of a trailing arm outer plate 4 and a trailing arm inner plate 5. The welding ports at both ends of the beam 1 are respectively welded to the inner plate 5 of the longitudinal arm. The front bushing 2 is welded on the first ends of the trailing arm outer plate 4 and the trailing arm inner plate 5, and the front bushing assembly 3 is assembled in the front bushing 2. The trailing arm outer plate 4 and the trailing arm inner The second end of the plate 5 is welded with a brake base plate 6 . One side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com