Electric head die clearance adjusting device for blowing machine

An adjustment device and blow molding machine technology, applied in the field of blow molding machinery, can solve the problems of manufacturing, assembly, use, daily management and maintenance, complex structure, etc., achieve good energy saving effect, avoid time lag, and facilitate manufacturing and assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

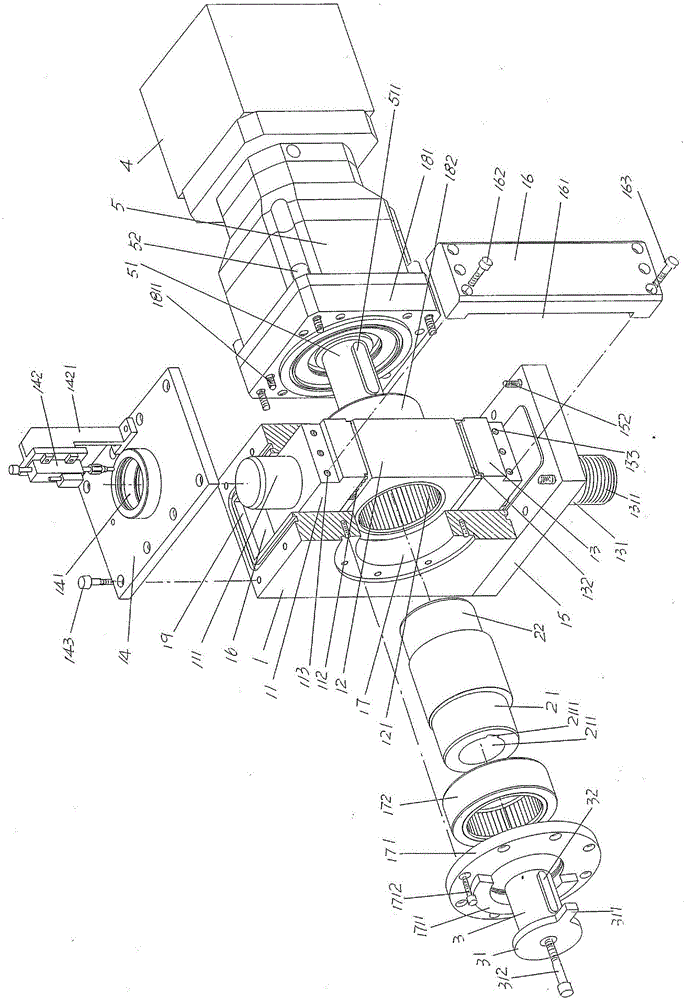

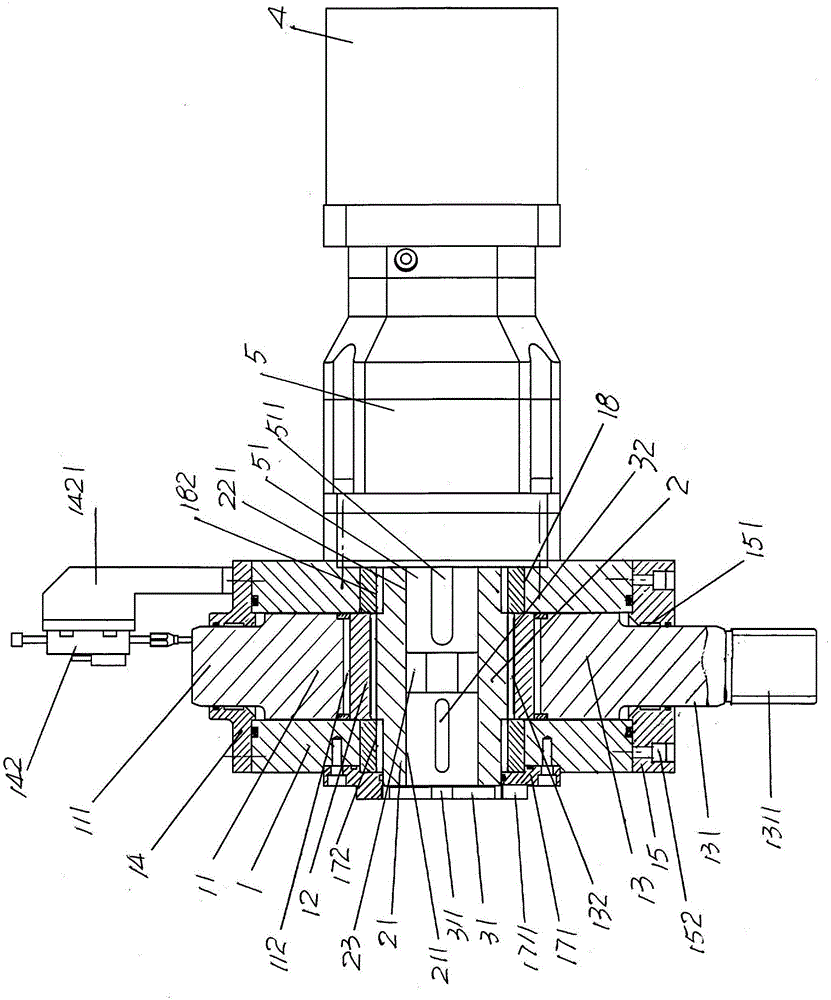

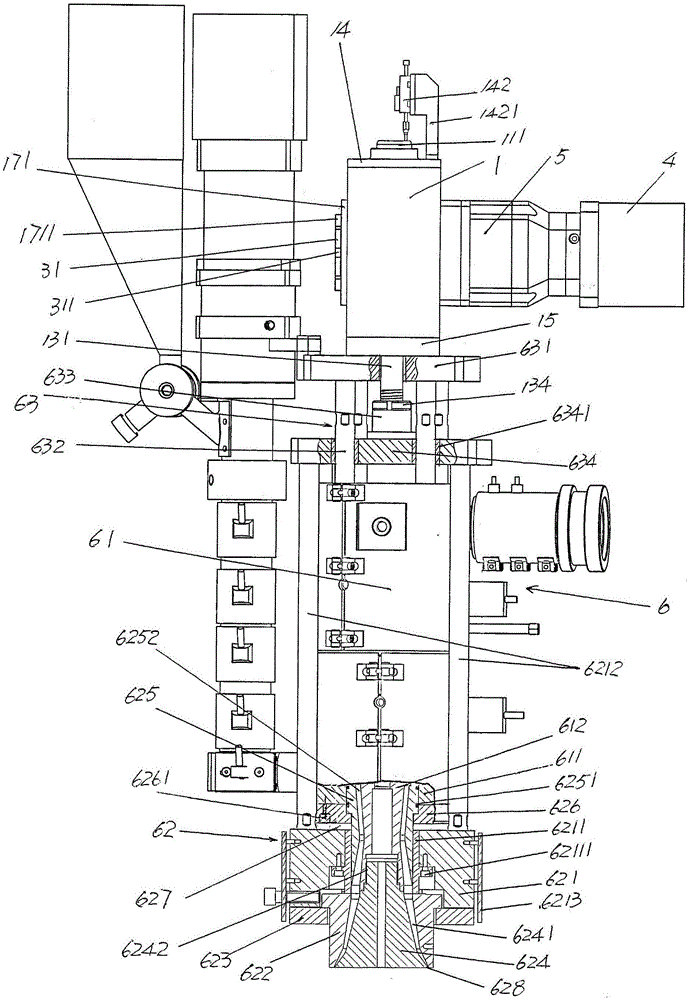

[0026] See figure 1 and figure 2, showing a box body 1, in which an upper slider 11, a cam sliding seat 12 and a slider 13 are sequentially arranged from top to bottom in the box body 1, and at the center of the upper side of the upper slider 11 There is an upper slider guide post 111 at the position, and there is a slider guide post 131 at the center of the lower side of the lower slider 13. The upper side of the cam sliding seat 12 is slidably matched with the upper slider 111, and the cam slides Seat 12 is slidably matched with lower slider 13 toward the side downwards, and an upper case cover 14 is fixed by upper case cover fixing screw 143 on the top of casing 1, and is fixed by lower case cover fixing screw 152 at the bottom of casing 1. The lower case cover 15 is respectively equipped with a slider fixing plate 16 at positions corresponding to the front side and the rear side of the cam sliding seat 12, the upper end of the slider fixing plate 16 is fixed with the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com