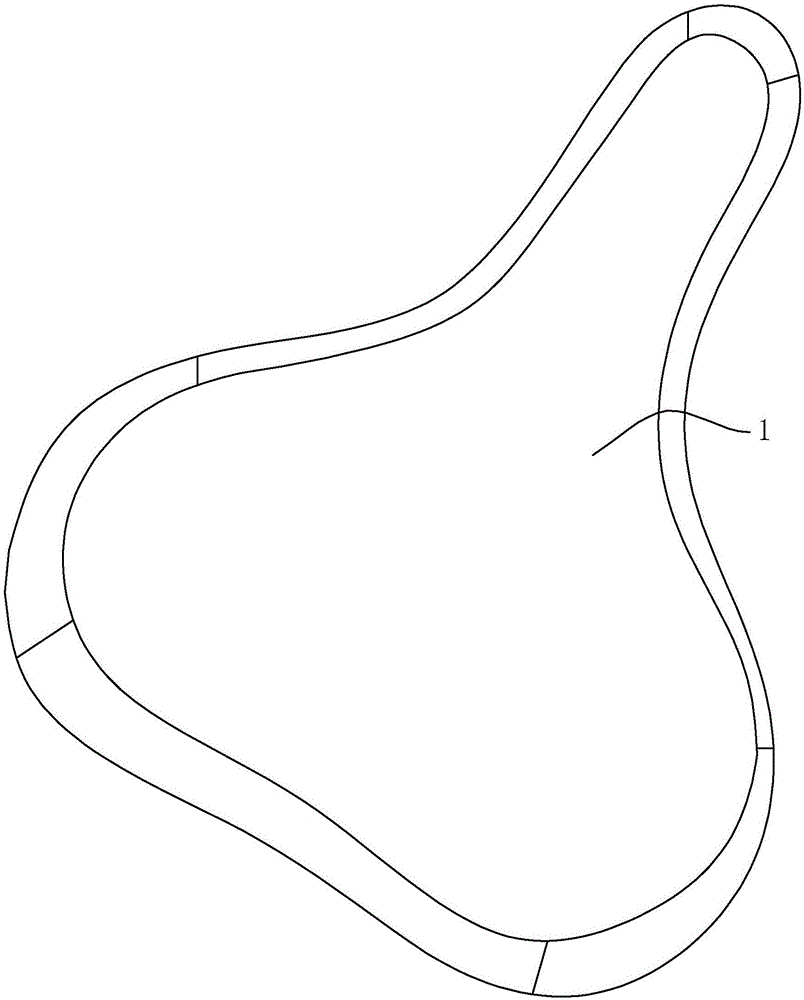

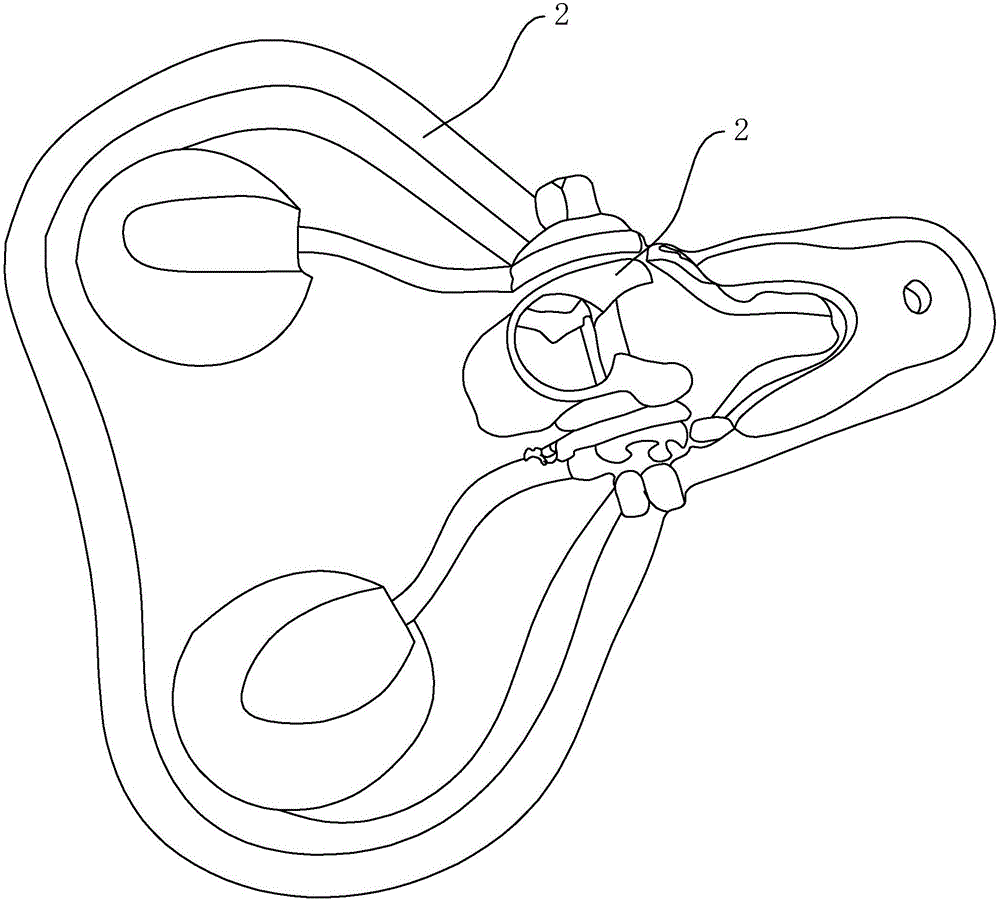

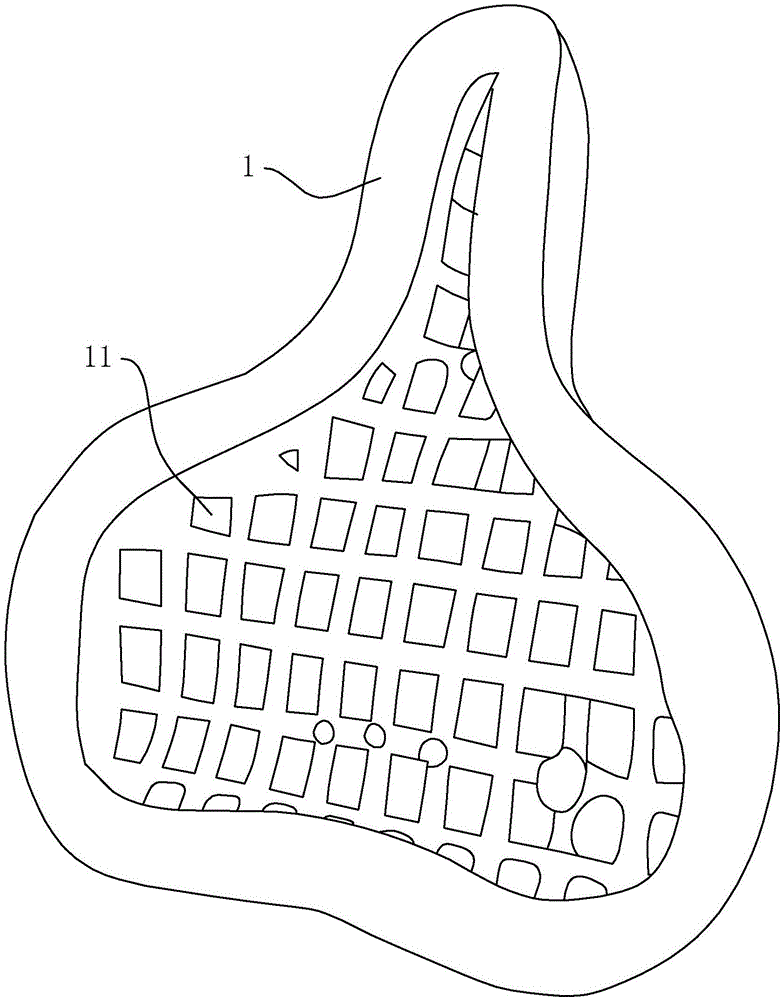

Bicycle saddle and machining method of cover leather thereof

A processing method and bicycle technology, applied to bicycle accessories, bicycle saddles, and other household appliances, can solve the problems of easy wear, breakage, and aggravated damage to seat cushions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for processing the cover of a bicycle seat cushion, comprising the steps of:

[0030] In step a, the plastic is melted at 150° C., and the plastic includes the following components: 100 parts of PVC, 90 parts of plasticizer, and 5 parts of foaming agent;

[0031] Step b, injecting the plastic in the molten state into the injection mold, blowing air into the mold for foaming during the process of injecting the mold, and the blowing pressure is 6MPa;

[0032] Step c, demoulding after cooling and forming.

Embodiment 2

[0034] A method for processing the cover of a bicycle seat cushion, comprising the steps of:

[0035] In step a, the plastic is melted at 160° C., and the plastic includes the following components: 100 parts of PVC, 95 parts of plasticizer, and 6 parts of foaming agent;

[0036] Step b, injecting the plastic in the molten state into the injection mold, blowing air into the mold for foaming during the process of injecting the mold, and the blowing pressure is 6MPa;

[0037] Step c, demoulding after cooling and forming.

Embodiment 3

[0039] A method for processing the cover of a bicycle seat cushion, comprising the steps of:

[0040] In step a, the plastic is melted at 170° C., and the plastic includes the following components: 100 parts of PVC, 100 parts of plasticizer, and 7 parts of foaming agent;

[0041] Step b, injecting the plastic in the molten state into the injection mold, blowing air into the mold for foaming during the process of injecting the mold, and the blowing pressure is 8MPa;

[0042] Step c, demoulding after cooling and forming.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com