Compression-molded cushion and preparation method thereof

A technology of compression molding and seat cushion, applied in the field of non-woven fabrics, can solve the problems of low production efficiency and high production cost, and achieve the effects of high production efficiency, low production cost and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of the above-mentioned molded cushion, the preparation method comprises the following steps in sequence:

[0042]Step 1: Lay down the exterior coating material 2 on the lower mold first, and then lay honeycomb cotton in the middle of the lower exterior coating material 2. Spray hot-melt adhesive or hot-melt powder on the edge where the edge portion 4 of the cushion is preformed, and then spread the upper surface coating material 1 on the honeycomb cotton to form a blank body, and the upper surface coating The positions of material 1 and lower surface coating material 2 correspond to each other;

[0043] Step 2: Start the upper mold and the lower mold to hot press the blank body. During hot pressing, the air pressure in the space surrounded by the upper mold and the lower mold is lower than atmospheric pressure. The temperature of hot pressing is 180-230°C. The pressing time is 20-180 seconds;

[0044] Step 3: Cool after the hot pressing is complet...

Embodiment 1

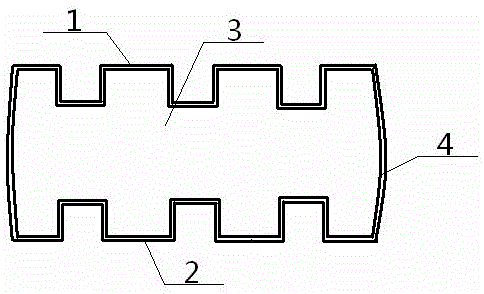

[0061] see figure 1 - image 3 , a molded seat cushion, comprising an upper surface covering material 1, a lower surface covering material 2 and an inner container 3, an inner liner is arranged between the middle part of the upper surface covering material 1 and the middle part of the lower surface covering material 2 liner 3, and the edges of the upper surface covering material 1 and the lower surface covering material 2 are connected to each other to form the cushion edge 4;

[0062] The inner liner 3 is honeycomb cotton, the upper surface covering material 1 and the lower outer surface covering material 2 are woven fabrics, knitted fabrics, non-woven fabrics or leather; the inner liner 3 is a formed three-dimensional structure, The bottom surface of the middle part of the upper surface covering material 1 is connected to the top surface of the inner container 3, and the bottom surface of the inner container 3 is connected with the top surface of the middle part of the lowe...

Embodiment 2

[0069] Basic content is the same as embodiment 1, the difference is:

[0070] On the product—both the top surface of the middle part of the upper surface covering material 1 and the bottom surface of the middle part of the lower surface covering material 2 are provided with printing or one of them is provided with printing.

[0071] In the preparation method——in the second step, before hot pressing the blank body, transfer printing paper is provided on the top and bottom surfaces of the blank body, or one of the two is provided with transfer printing paper. The dye on the pattern in the transfer printing paper is heat-treated to transfer the dye to the blank body to form a print; in the third step, after the heat pressing is completed, the printed transfer printing paper needs to be removed.

[0072] When printing, it can be printed on the top surface and the bottom surface of the cushion at the same time, or it can be printed on only one of the top surface or the bottom surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com