Beef back strap shredding equipment

A technology of beef ribs and shreds, which is applied in metal processing and other fields, can solve the problems of low production efficiency, unattractive shape, expensive unit price of equipment, etc., and achieve the effect of simple and compact structure, low price and easy market promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

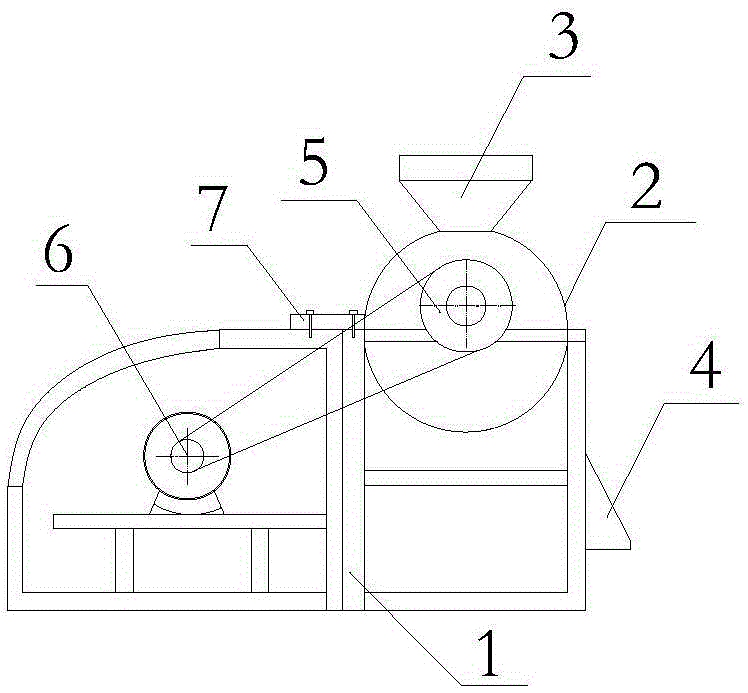

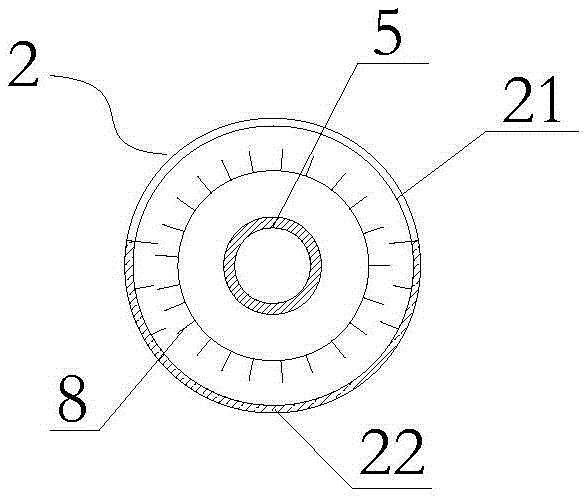

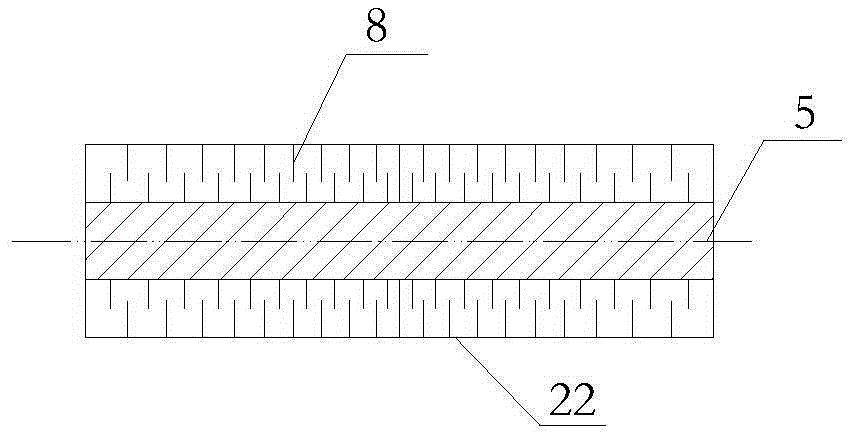

[0016] Such as figure 1 , 2 , 3, the beef tendon shredding equipment of the present embodiment includes a frame 1, a cutting machine body installed on the front upper part of the frame 1 and a motor 7 installed on the rear lower part of the frame 1, and the cutting machine body includes Hollow cylindrical outer casing 2 and a cutting shaft 5 arranged inside it, the axis of the rotating shaft 5 is parallel to the outer casing 2 and the two ends pass through the two end faces of the outer casing 2 respectively, the outer surface of the cutting shaft 5 and the inner wall of the outer casing 2 are arranged There are cutting blades 8 that cooperate with each other; the cutting shaft 5 is connected to the motor 7 through a pulley, the upper side wall of the outer shell 2 is provided with a raw material inlet 3, and the lower end side wall is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com