Hobbing cutter device for rubber cutting

A technology of hob and rubber, which is applied in the field of hob device for rubber cutting, which can solve the problems of low work efficiency, failure to exert the maximum function of the equipment, and difficulty in cutting rubber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

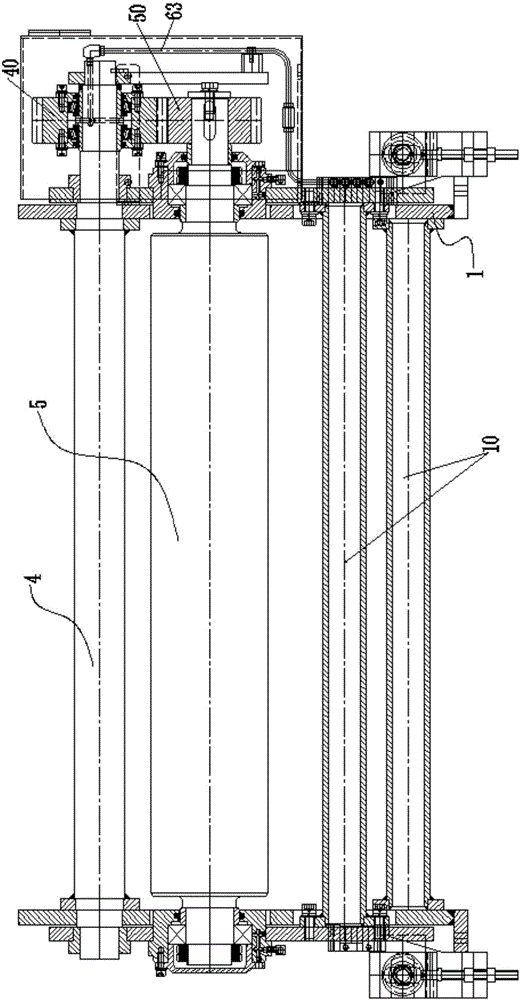

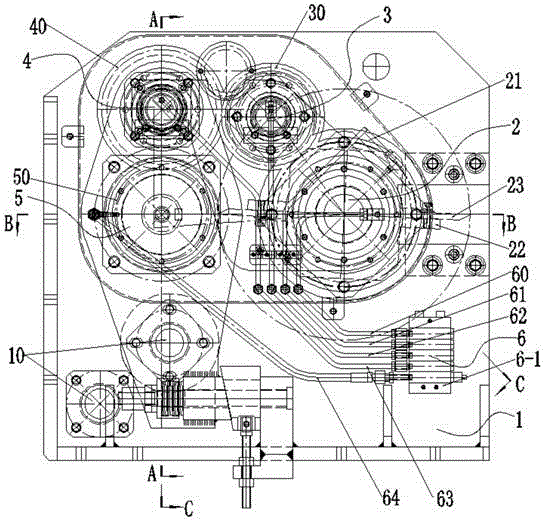

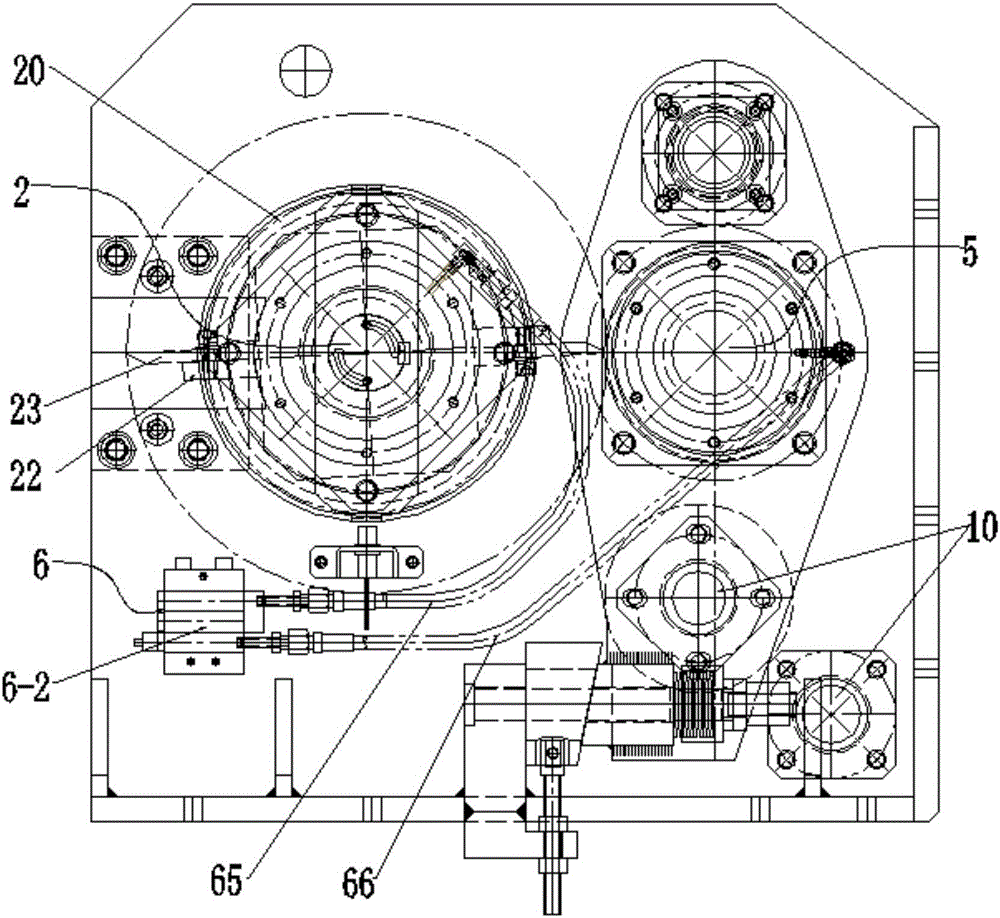

[0020] Such as Figure 1 to Figure 7 As shown, the present invention is a hob device for rubber material cutting, which is used to improve the safety of storage and transportation of powder materials.

[0021] Specifically, if Figure 1 to Figure 7 As shown, it includes frame 1, hob shaft 2, reversing shaft 3, retaining shaft 4, anvil roller 5 and lubrication system 6, such as figure 1 , figure 2 and image 3 As shown, the lower end of the frame 1 is provided with two braces 10, such as Figure 4 , Figure 5 As shown, both ends of the hob shaft 2 are connected with the frame 1 through beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com