Gas static pressure platform and clearance adjustment method thereof

A gap adjustment method and aerostatic pressure technology, which are used in large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of easy to produce air hammer phenomenon, affect the stability of the stage, and increase the spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

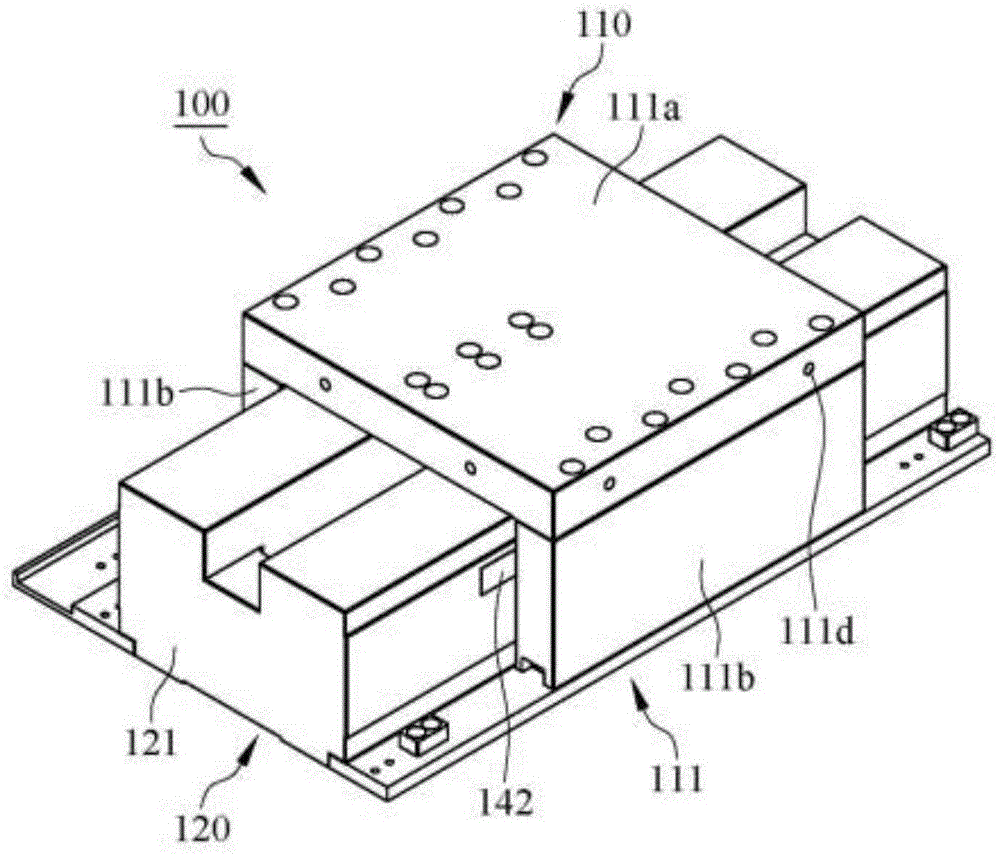

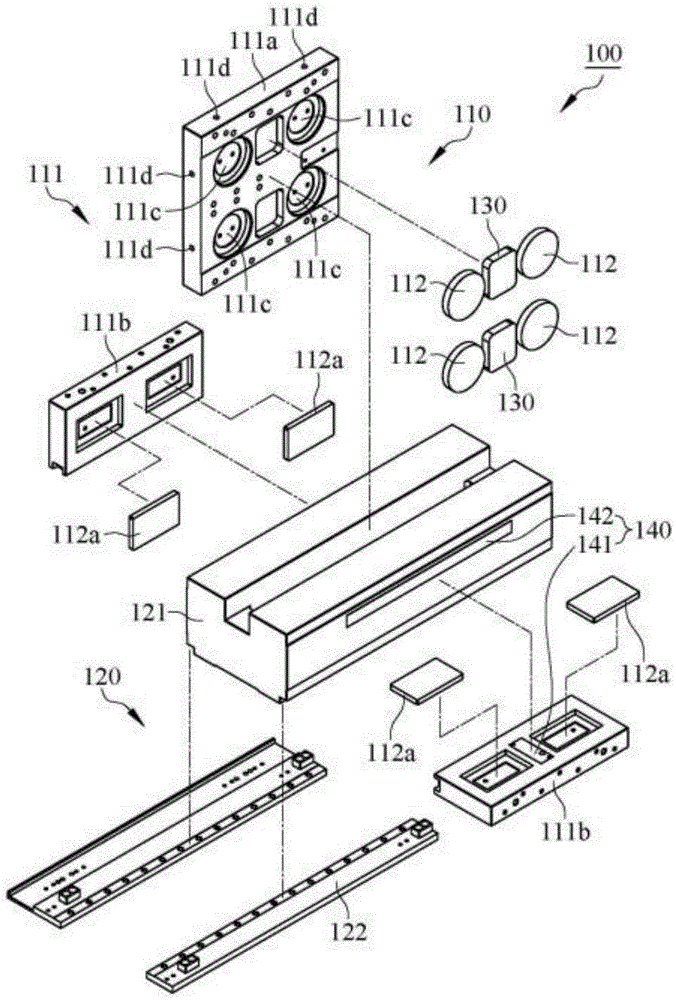

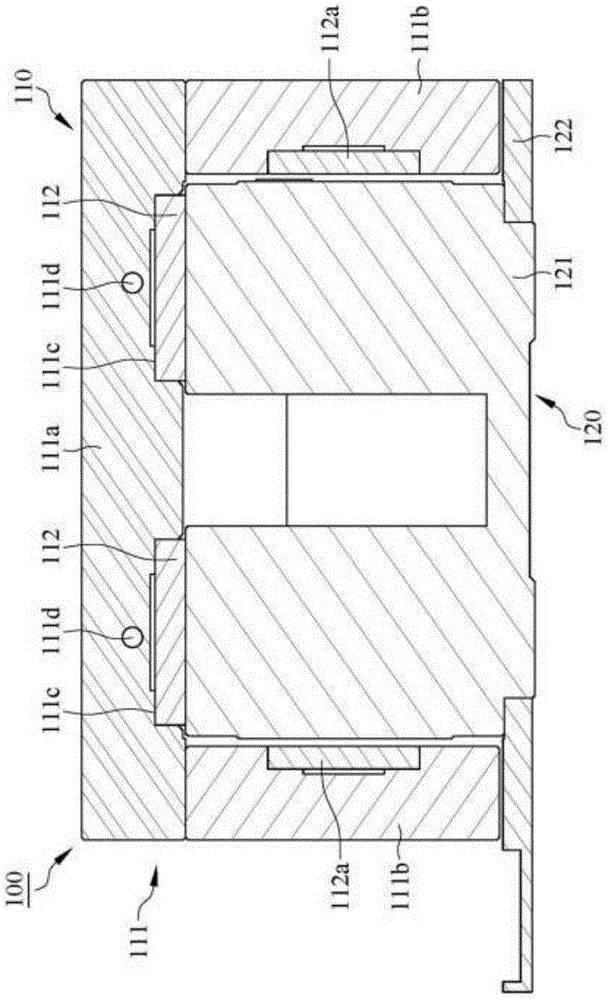

[0040] see Figure 1 to Figure 3 , a gas static pressure platform 100 of the present invention is used in precision equipment such as an exposure machine for optoelectronic semiconductors, a precision processing machine, or a positioning platform for measuring equipment. The gas static pressure platform 100 includes a platform 110 and a track 120 And at least one electromagnet 130, the stage 110 is arranged on the track 120, and the stage 110 moves along the track 120, the stage 110 has a carrier 111 and at least one aerostatic bearing 112, the aerostatic bearing 112 is set on the carrier 111, the aerostatic bearing 112 can be made of a porous throttling component, and the material of the aerostatic bearing 112 can be selected from materials with microporous structures such as porous graphite, ceramics or copper. In this embodiment, the aerostatic bearing 112 is located between the carrier 111 and the rail 120, the carrier 111 has at least one groove 111c and at least one thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com