Welding device

A welding device and matching connection technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of high welding machine, easy arc generation, and electric shock of users, so as to reduce the workload of personnel and improve operation stability , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

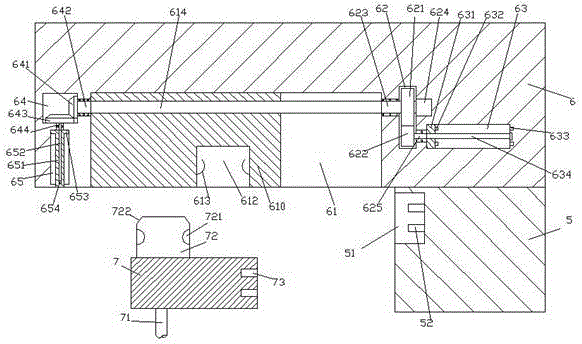

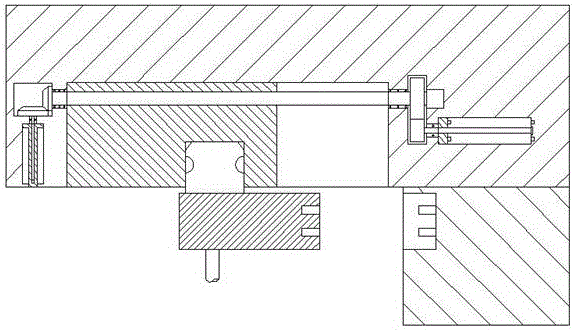

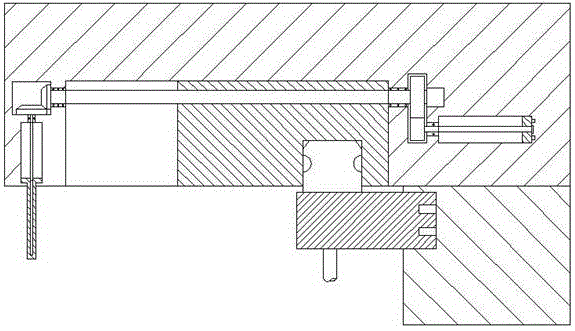

[0023] Such as Figure 1-Figure 4 As shown, a welding device of the present invention includes a support column 5, a beam 6 fixed on the top of the support column 5 and extended to the left, and a plug 7 mated with the beam 6. The support column 5 An insertion slot 51 is provided in the left end surface, and a second insertion piece 52 is provided on the inner wall of the right side of the insertion slot 51. A sliding groove 61 is provided in the bottom end surface of the left extension section of the crossbeam 6, and the sliding groove 61 There is a first screw rod 614 extended from left to right inside, and the helical pattern on the first screw rod 614 is connected with a pushing block 610, and the beam 6 on the left side of the sliding groove 61 is provided with a first force transmission chamber 64, the beam 6 below the first force transmission cavity 64 is provided with a first sliding cavity 65, the beam 6 on the right side of the sliding groove 61 is provided with a se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com