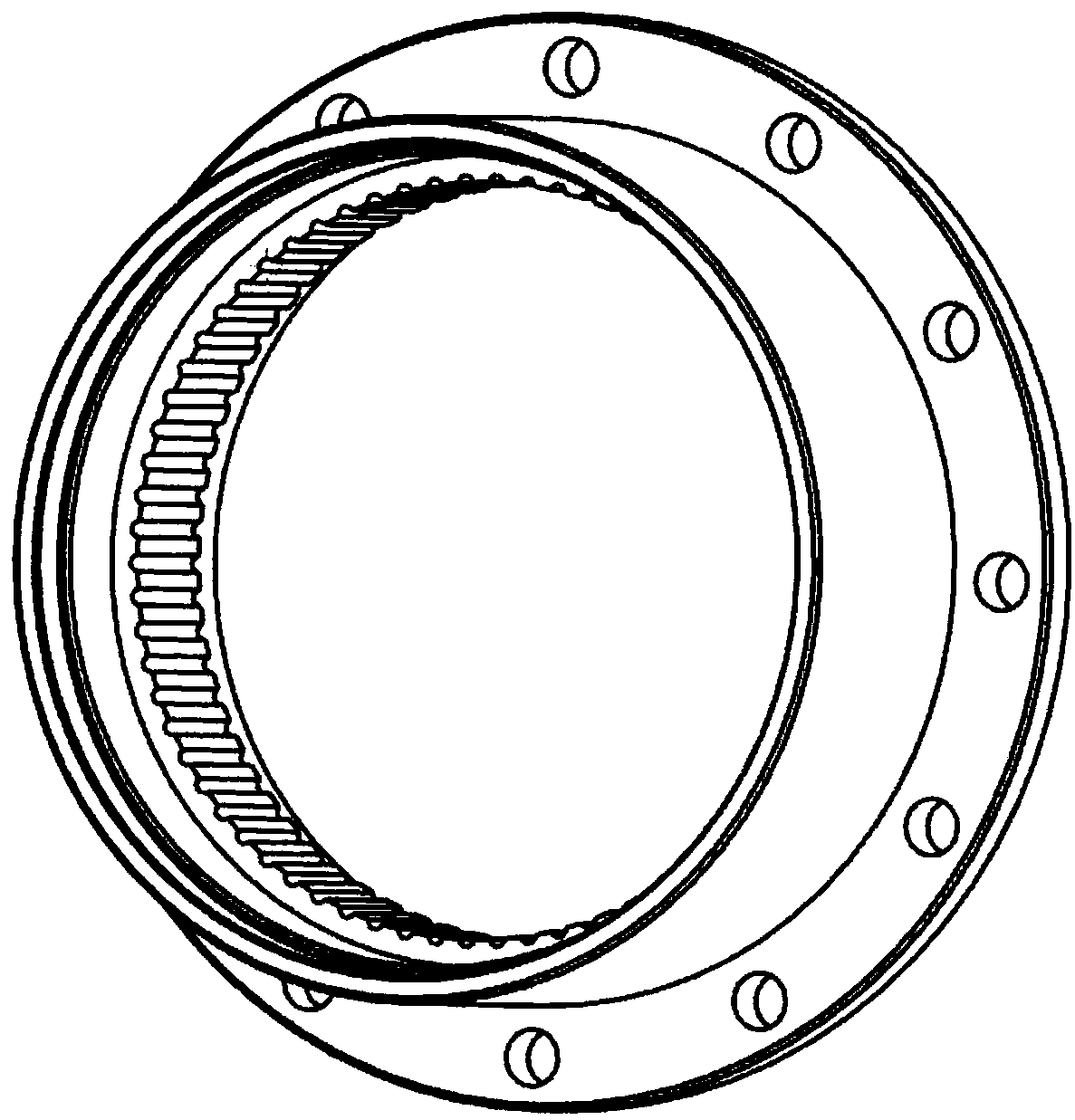

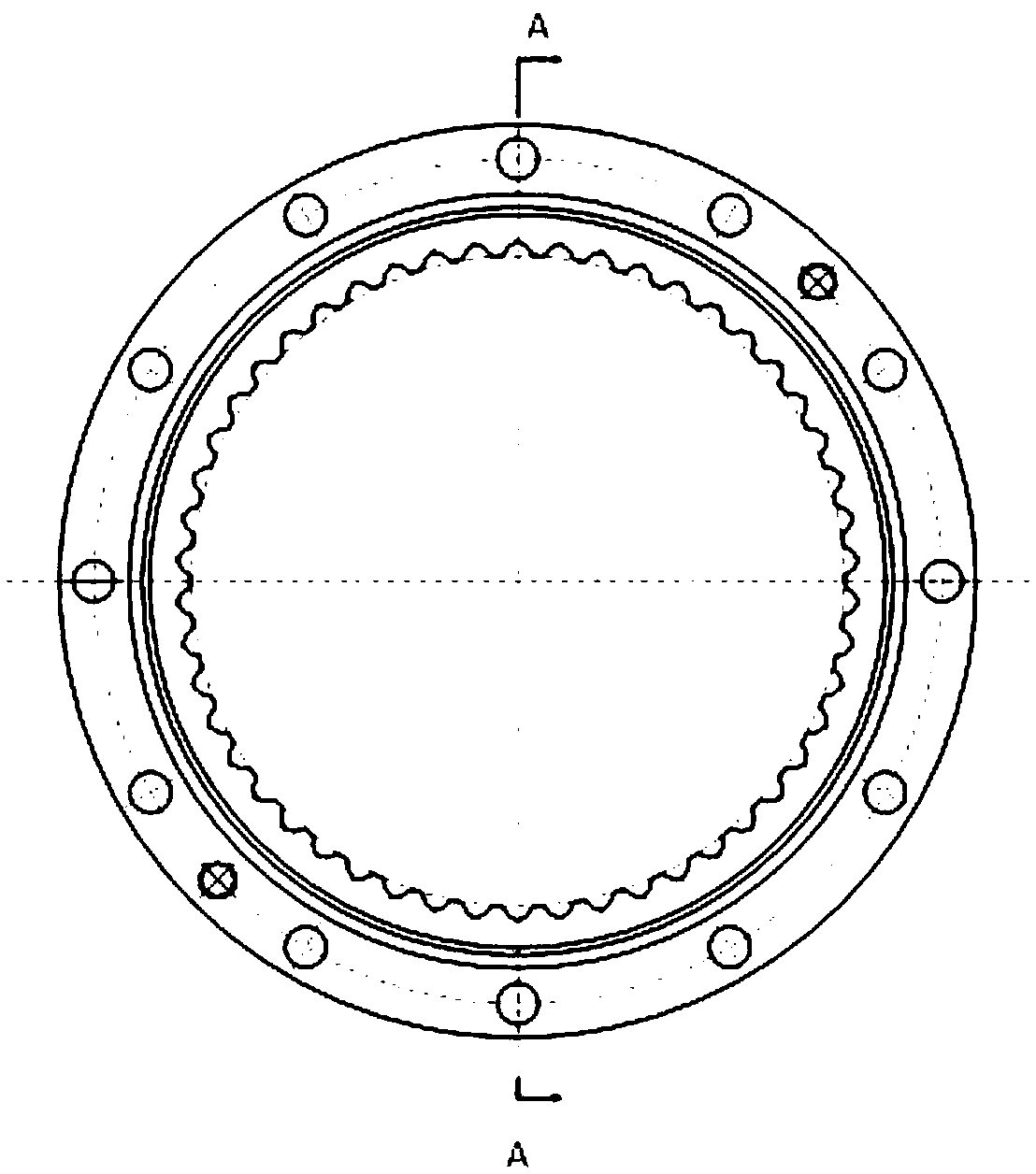

Machining Technology of Internal Gear of Precision Planetary Reducer with Less Tooth Difference

A technology of planetary reducer and processing technology, applied in the direction of belt/chain/gear, gear teeth, components with teeth, etc., can solve the problem of no research results reported on internal gears, etc., to reduce the cost of the whole machine and reduce parts The effect of the number and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

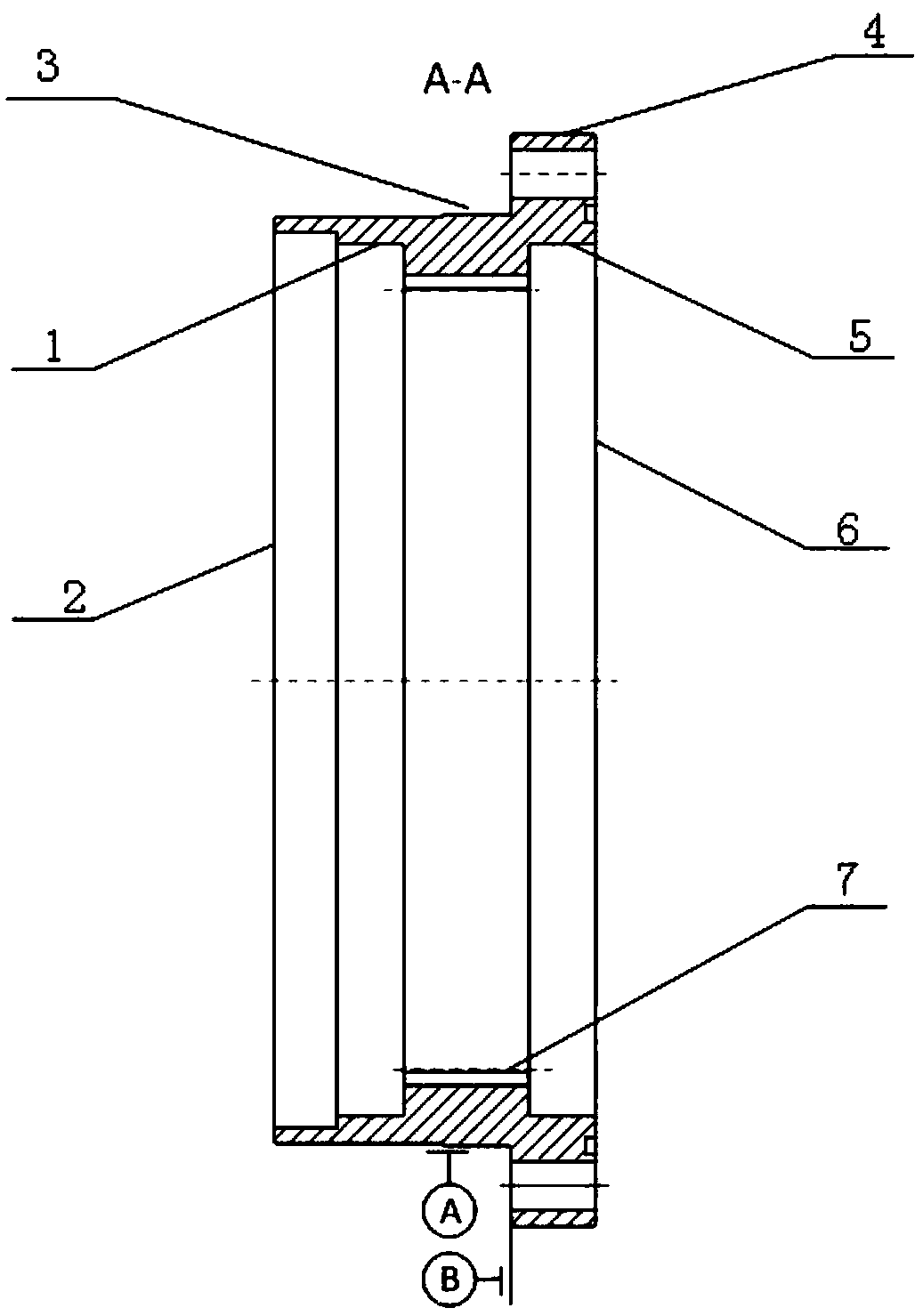

[0031] 1) Forging: The material is low-carbon high-quality alloy steel, and the blank is forged by die forging;

[0032] 2) Isothermal normalizing, the hardness of isothermal normalizing is HB160-190;

[0033] 3) Rough turning: the outer circle of the rough turning blank, the left and right end faces are flat, leaving a process allowance of 0.5mm to ensure the processing size; Axis, perpendicularity to the end face;

[0034] 4) Shaping: Based on the bearing raceway 5, use a special slotting tool to process the arc-shaped containment groove 7 of the internal gear, leaving a margin of 0.5mm;

[0035] 5) Heat treatment: Carburize and quench the raceways 1 and 5 and the inner gear arc containment groove 7, the depth of the carburized layer is 1-1.2mm, the surface hardness is HRC58-62, and the rest of the parts are treated with anti-seepage;

[0036] 6) Coarse grinding: with A as the reference, coarsely grind the right end face 6, the outer circle 4 and the bearing raceway 5 to e...

Embodiment 2

[0043] 1) Forging: The material is high-strength medium carbon steel, and the blank is forged by die forging;

[0044] 2) Isothermal normalizing, the hardness of isothermal normalizing is HB160-190;

[0045] 3) Rough turning: the outer circle of the rough turning blank, the left and right end faces are flat, leaving a process allowance of 0.5mm to ensure the processing size; Axis, perpendicularity to the end face;

[0046] 4) Shaping: Based on the raceway 5, use a special slotting tool to process the arc-shaped containment groove 7 of the internal gear, leaving a margin of 0.5mm;

[0047] 5) Heat treatment: local high-frequency quenching treatment for raceways 1, 5 and inner gear arc containment groove 7;

[0048] 6) Coarse grinding: with A as the reference, coarsely grind the right end face 6, the outer circle 4 and the bearing raceway 5 to ensure the coaxiality between the outer circle 4 and the bearing raceway 5, and the perpendicularity between the end face 6 and the bea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com