Safety servo press control system

A servo press and control system technology, applied in the field of presses, can solve the problems of lower precision of stamping parts, large drift of the bottom dead center of the slider, damage to machine tool equipment and working molds, etc., and achieve the effect of avoiding uncontrolled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

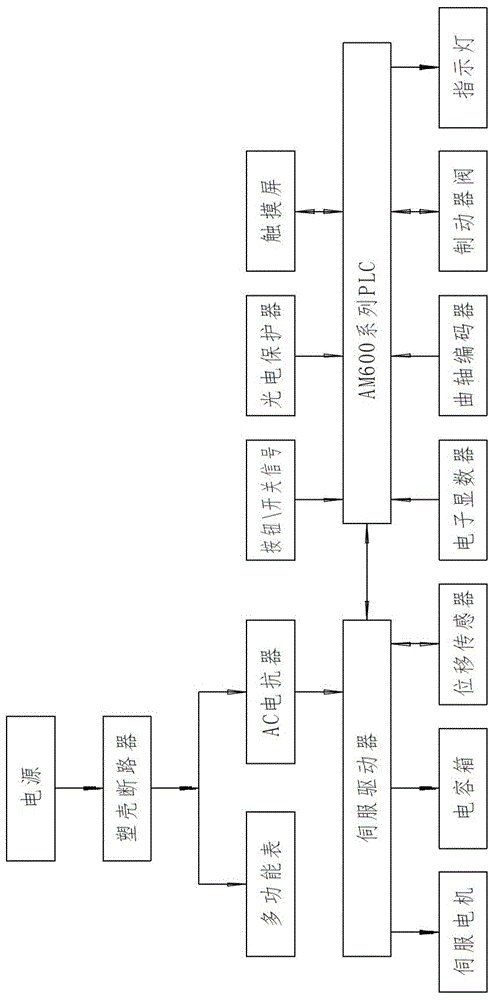

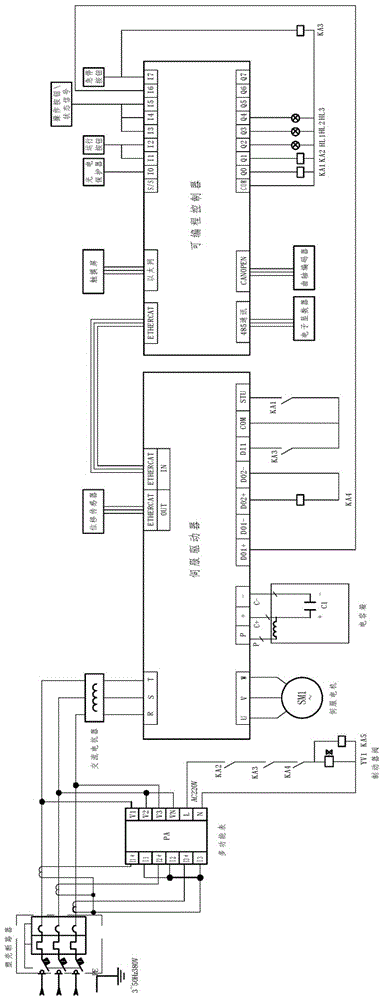

[0071] Such as Figure 1-5 A safe servo press control system shown, including a servo control unit, a PLC control unit and a power control unit;

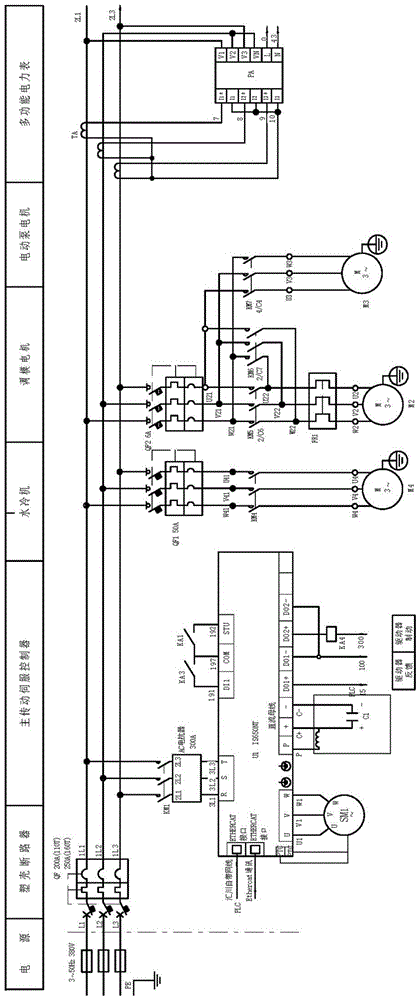

[0072] The servo control unit includes a main drive servo controller connected to a three-phase power supply, a water cooler, a mold adjusting motor, an electric pump motor and a multifunctional electric meter. The output end of the main drive servo controller is connected to a main drive servo motor. The transmission servo controller also performs data communication with the slider displacement sensor and the PLC control unit. The main transmission servo controller is also connected with the intermediate relay. The main transmission servo driver uses the Inovance IS650NT series servo controller. The main transmission The power input end of the servo controller is connected to the three-phase power supply via a reactor, the ETHERCAT input port of the main drive servo controller is connected to the PLC, and the ETHERCAT output port o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com