Safe and stable multifunctional wall climbing paint spraying robot

A safe, stable and robotic technology, applied to spraying devices with movable outlets, spraying devices, elastic suspensions, etc., can solve the problems of single function, labor and material, and inability to effectively spray paint, etc., to achieve ease of use and ease of manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention can be explained in more detail by the following examples, and the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention, and the present invention is not limited to the following examples:

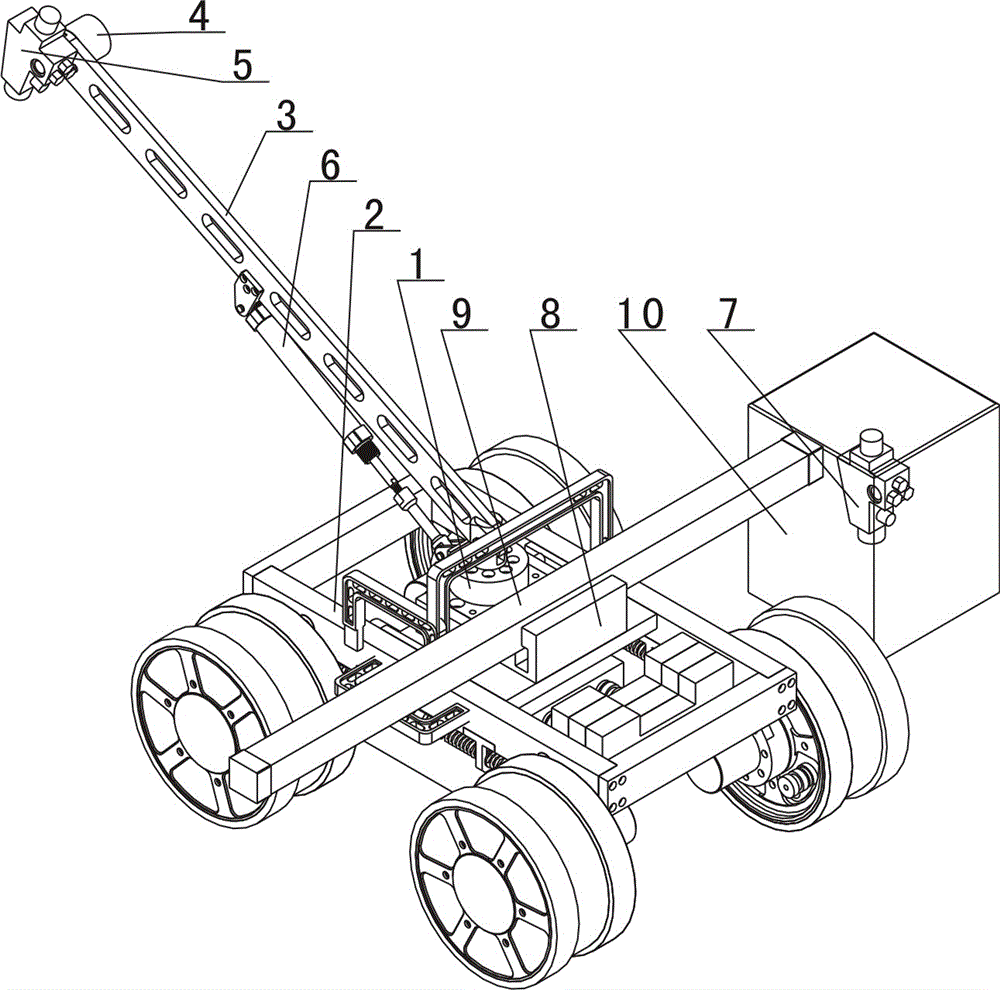

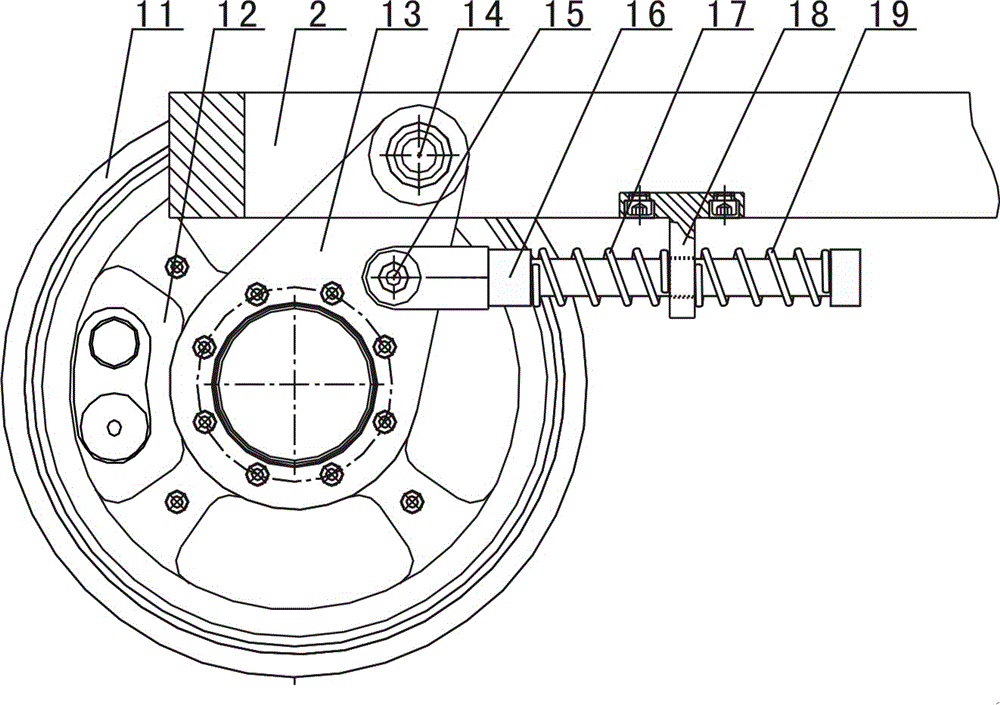

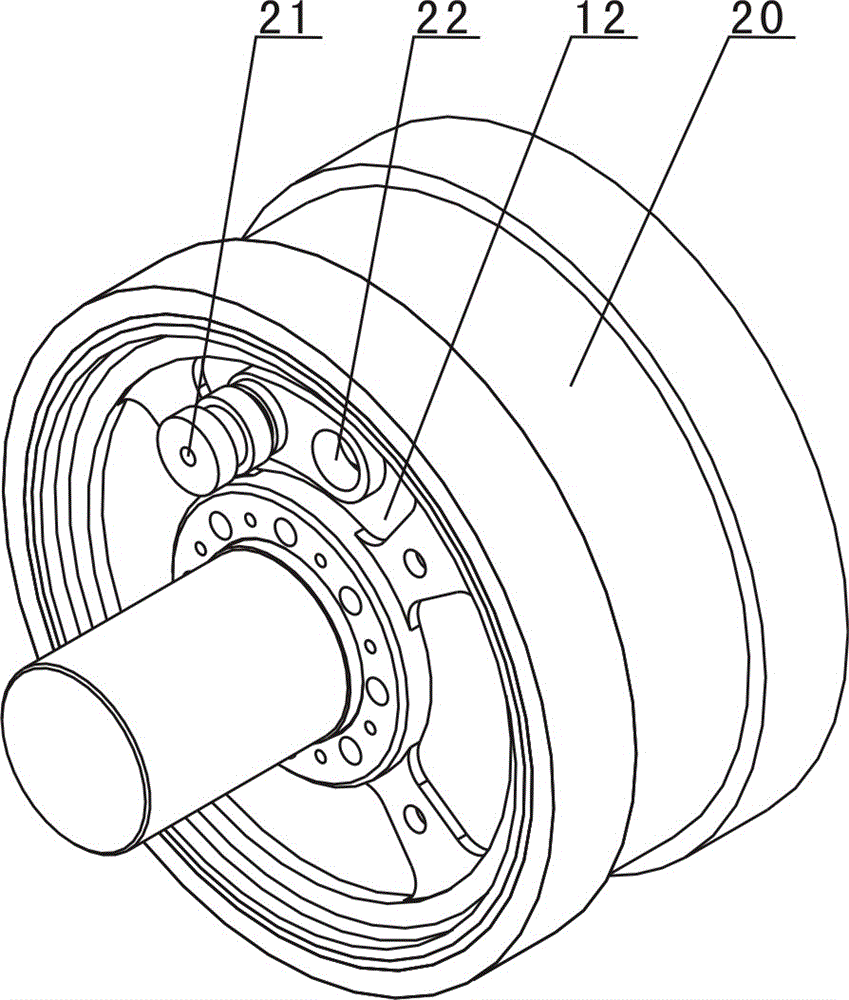

[0035] combined with figure 1The safe and stable multifunctional wall-climbing painting robot includes a painting device and elastic wheels; the painting device includes a main rotating cylinder 1, a mechanical arm 3, an auxiliary rotating cylinder 4, a main spraying nozzle 5, a telescopic cylinder 6 and a lateral Paint spraying device; the main rotary cylinder 1 includes a fixed plate located at the bottom and a rotating plate hinged on the upper part of the fixed plate, the fixed plate is correspondingly fixed on the upper surface of the wall-climbing painting robot car body 2, and the upper part of the rotating plate faces It should be hinged with the bottom end of the mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com