Device for preparing emulsified liquid

A technology of emulsion and liquid preparation, which is applied in the directions of transportation and packaging, mixer accessories, chemical instruments and methods, etc., and can solve problems such as the efficiency of liquid preparation needs to be improved, the labor intensity is high, and the emulsion cannot meet the requirements of use, etc. , to achieve the effect of ensuring good operation, low labor intensity, and improving the quality of liquid supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

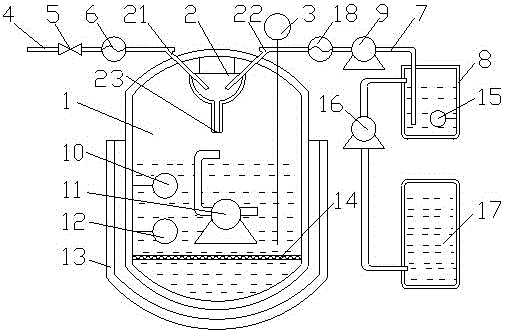

[0019] Such as figure 1 As shown, a kind of device that the present invention proposes is used for emulsion dosing, comprises: dosing box 1, mixer 2, concentration sensor 3, solenoid valve 5, water flow meter 6, gear oil pump 9, frequency converter and control device;

[0020] The mixer 2 and the concentration sensor 3 are arranged in the liquid distribution box 1, the mixer 2 includes a liquid inlet and a liquid outlet 23, a mixing chamber is formed between the liquid inlet and the liquid outlet 23, and the liquid inlet includes a The water inlet 21 and the oil inlet 22 on both sides of the mixer 2, the water inlet 21 is connected to the external water source through the water inlet pipe 4, the electromagnetic valve 5 and the water flow meter 6 are arranged on the water inlet pipe 4, and the oil inlet 22 is connected to the external water source through the water inlet pipe 4. The oil pipe 7 is connected to the oil storage tank 8, and the gear oil pump 9 is arranged on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com