Falling-film evaporation efficient gas and liquid mixer

A gas-liquid mixer, falling film evaporation technology, applied in the direction of evaporator liquid feeder, gas and gas/vapor mixing, evaporator accessories, etc., can solve the disadvantage of saving investment and maintenance costs, and low liquid heat exchange and gasification efficiency. , gas passing through the pressure drop and other problems, to ensure safe and reliable operation, easy automatic control, uniform gas-liquid mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

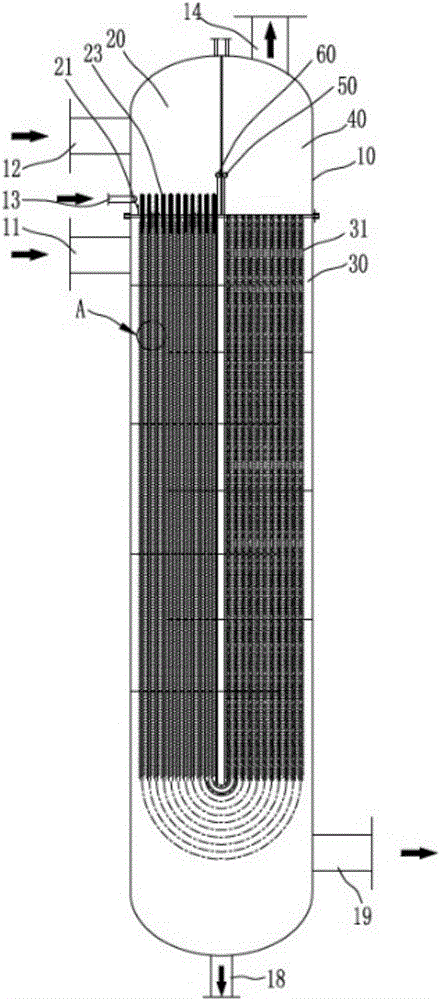

[0039] Such as Figure 1 to Figure 8 As shown, the falling film evaporation high-efficiency gas-liquid mixer includes a cylinder 10, and the cylinder 10 is divided into a feed chamber 20, a main evaporation mixing chamber 30 and a discharge chamber 40;

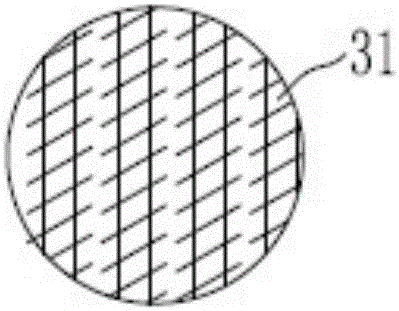

[0040] The cylinder body 10 is provided with a heating gas inlet 11 communicating with the main evaporation mixing chamber 30, and the bottom of the cylinder body 10 is provided with a cooling liquid outlet 18 after heat exchange and a cooling gas outlet 19. The main evaporation mixing chamber 30 is provided with a number of outer finned heat exchange tubes 31, the fins on the outer finned heat exchange tubes 31 are arranged obliquely, which is beneficial to the gas-liquid separation when the heating gas is liquefied while enhancing heat transfer; A refilming device 32 is arranged inside the fin heat exchange tube 31, and its large airflow hole will facilitate the passage of airflow, and can collect the non-atomized liquid bef...

Embodiment 2

[0051] refer to Figure 9 , the structural principle of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated. The only difference is:

[0052] In this embodiment, the outer finned heat exchange tube does not adopt a U-shaped structure, but includes a feed pipe and a discharge pipe arranged in parallel, and floating head pipes are installed at the bottom ends of the feed pipe and the discharge pipe Plate 71, the lower part of the floating head tube plate 71 is provided with a floating head 72, the floating head 72 and the floating head tube plate 71 jointly form an auxiliary evaporation mixing chamber 70, the feed pipe and the discharge pipe It communicates through the auxiliary evaporation mixing chamber 70, and a steam heat exchanger 73 is installed in the auxiliary evaporation mixing chamber 70. The heat exchange tubes of the steam heat exchanger 73 are preferably arranged in a serpentine winding manner, and the lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com