Segmenting potato roller washing device

A technology for cleaning equipment and drums, applied in applications, food processing, food science, etc., can solve problems such as easy loss and severe collision, and achieve the effect of reducing collision damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

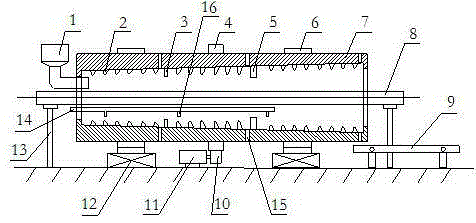

[0013] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0014] Such as figure 1 As shown, the segmented potato drum cleaning equipment of this embodiment, the segmented potato drum cleaning equipment, comprises a cylindrical drum 7, and the left end of the drum 7 is provided with a feeding port (feeding funnel 1 in the figure), and the right end is provided with a There is a discharge port, the inner wall of the drum 7 is provided with elastic protrusions 2, the left end of the drum 7 is provided with a clear water input pipe 14, the clear water input pipe 14 is provided with a clear water nozzle 16, and the inner wall of the drum 7 is also provided with The ring-shaped left retaining ring 3 and the right retaining ring 5, the height of the left retaining ring 3 is lower than the right retaining ring 5, and the left and right retaining rings divide the drum 7 into three sections: left, middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com