Chicken feed and preparation method thereof

A chicken feed and raw material technology, applied in animal feed, animal feed, application and other directions, can solve the problems of gall and rattan tea that have not been seen, and achieve the effect of enhancing the antiviral effect, improving the efficiency of raising chickens, and reducing respiratory diseases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

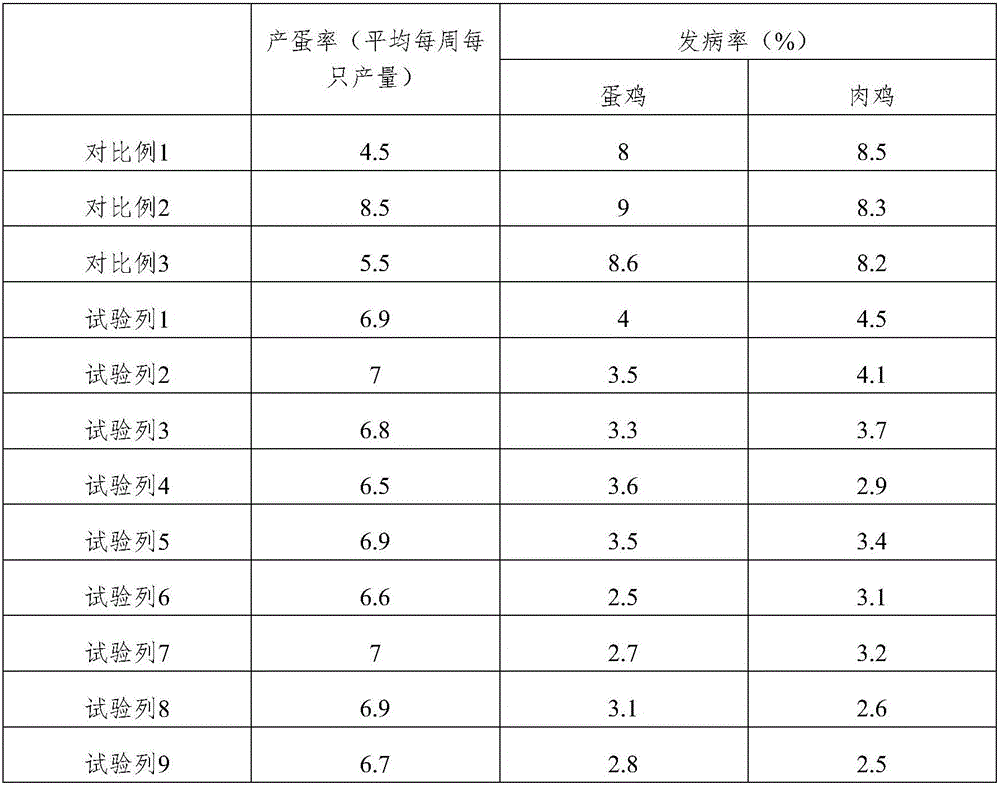

Examples

Embodiment 1

[0032] A chicken feed, the raw material is 20kg of corn, 5kg of additives, 0.0001kg of fermenting bacteria; among them, the additive is a mixture of 3kg of gallnut and 1kg of rattan tea; the fermenting bacteria are lactic acid bacteria, yeast, and spores in a mass ratio of 1:0.3: 1.3 Mixed mixed bacteria. The preparation method is to mix and crush corn and additives into powder, stir in fermenting bacteria, stir evenly, and ferment for 1-3 days to prepare.

Embodiment 2

[0034] A chicken feed. The raw materials are 30kg of grain, 9kg of additives, and 0.007kg of fermenting bacteria. Among them, the additive is a mixture of 7kg of gallnut and 5kg of rattan tea; the fermenting bacteria are lactic acid bacteria, yeast, and spores in a mass ratio of 1:0.7: 1.9 Mixed mixed bacteria; the preparation method is to pulverize the additives into powder, then add the fermentation bacteria, at a temperature of 30-40 ℃, control the moisture content of 45-57%, 5-7 days after the fermentation process, then add to the grain, Grind in a grinder and pass through a 100-130 mesh sieve. The grain used is a mixture of corn and rice husk in a mass ratio of 2:0.5.

Embodiment 3

[0036] A chicken feed, the raw materials by weight are 25kg of grain, 7kg of additives, and 0.004kg of fermentation bacteria;

[0037] Among them, the raw materials of the additives are 5kg of gallnut and 3kg of rattan tea by weight;

[0038] The fermenting bacteria are mixed bacteria of lactic acid bacteria, yeasts, and spores in a mass ratio of 1:0.3:1.9.

[0039] The preparation method includes the following steps:

[0040] (1) The grain is crushed and passed through a 10-mesh sieve to obtain grain powder;

[0041] (2) Mix the additives and water at a mass ratio of 1:3, freeze and soak them at a temperature of 3°C for 3 days, then grind them into a slurry, pass through a 40-mesh sieve, and heat to 60°C in a microwave for 20 minutes, spray Dry to obtain additive powder;

[0042] (3) Mix the grain powder, additive powder, and fermentation bacteria, adjust the moisture content to 40%, the temperature is 60°C, ferment for 3 days, granulate, pass through a 20-mesh sieve, and package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com