A power-saving device for real-time improvement of power factor at the end of the power grid

A power-saving device and power factor technology, applied in circuit devices, emergency protection circuit devices for limiting overcurrent/overvoltage, emergency protection circuit devices, etc., can solve the problem of equipment output reduction, failure to achieve compensation, and increased power consumption Equipment and other problems to achieve the effect of improving load carrying capacity, avoiding inaccurate compensation, and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] An energy-saving device for improving power factor at the end of a power grid in real time, comprising a chassis and an energy-saving device body disposed in the chassis, the power-saving device body comprising:

[0022] The integrated control unit automatically detects the current signal in the grid in real time through the acquisition unit, and then sends it to the control chip for precise calculation, so that the output compensation current changes with the change of the detected current;

[0023] Safety protection device, through the use of low-voltage control circuit to improve the safety of manual operation;

[0024] Bypass control unit, when the device is in the bypass state, it can automatically switch to the bypass state when it detects that the compensated reactive power meets the reactive power required by the end, so that the phenomenon of reactive power overcompensation will not occur. By controlling the contactor group When the power-saving device itself f...

Embodiment 2

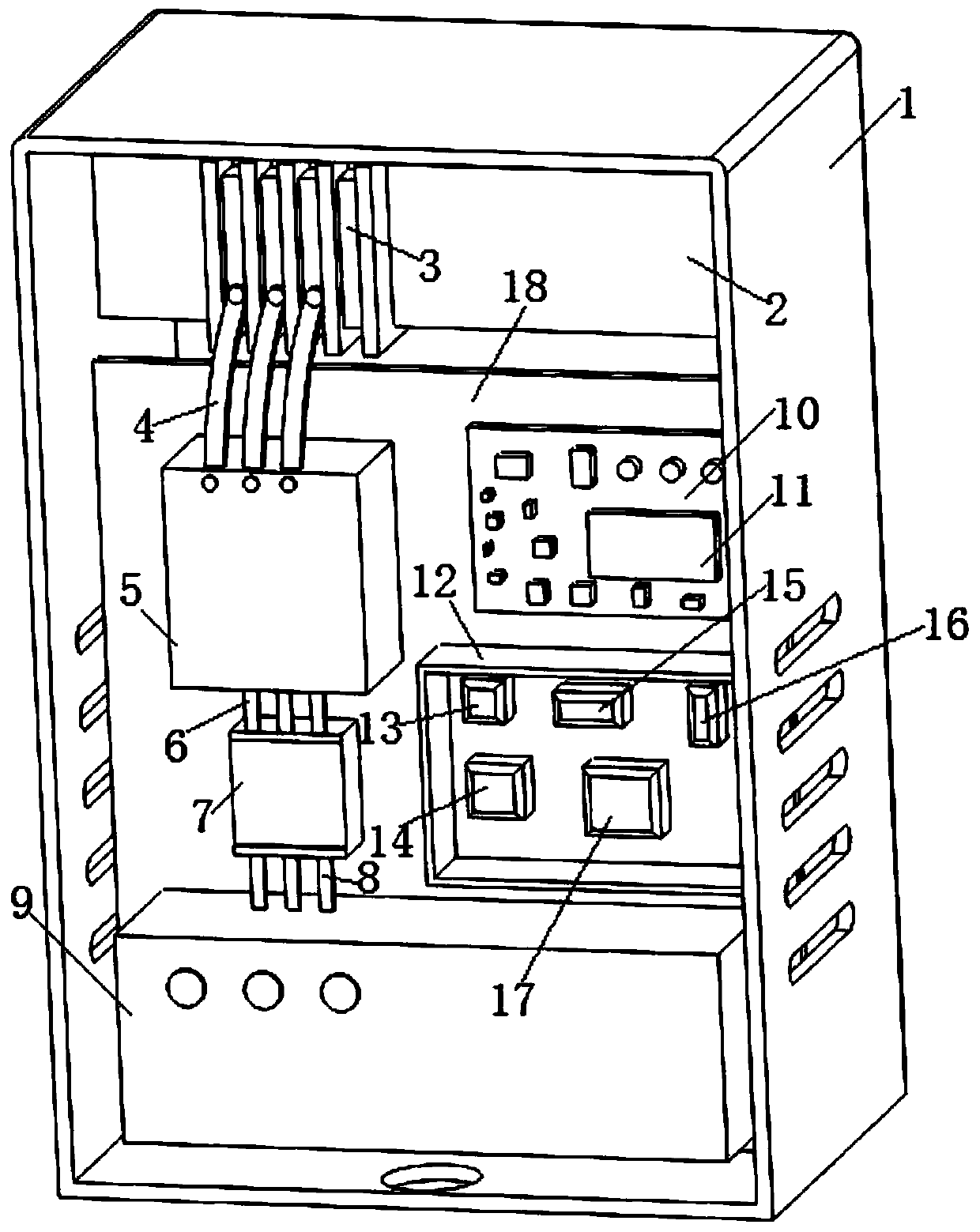

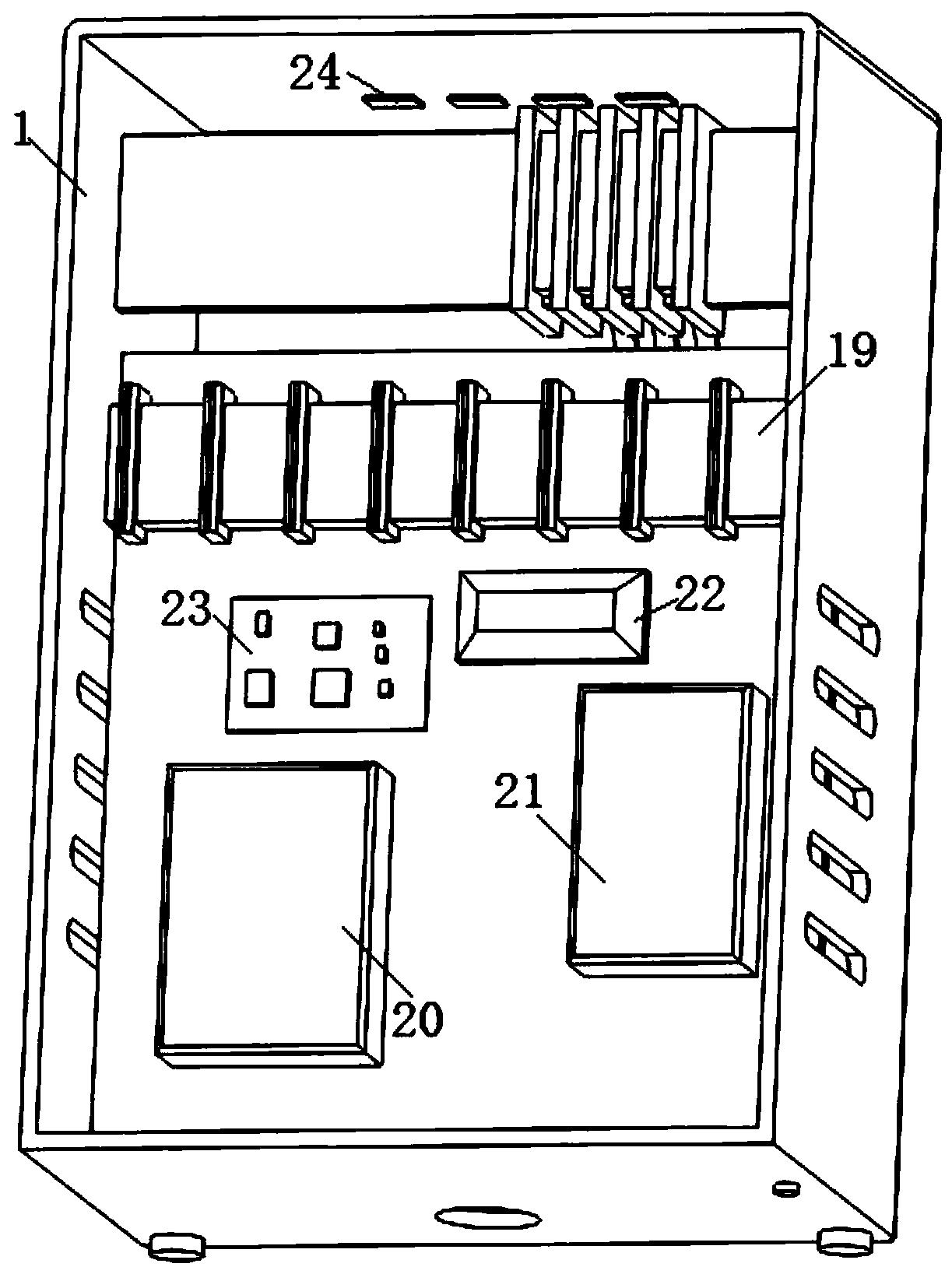

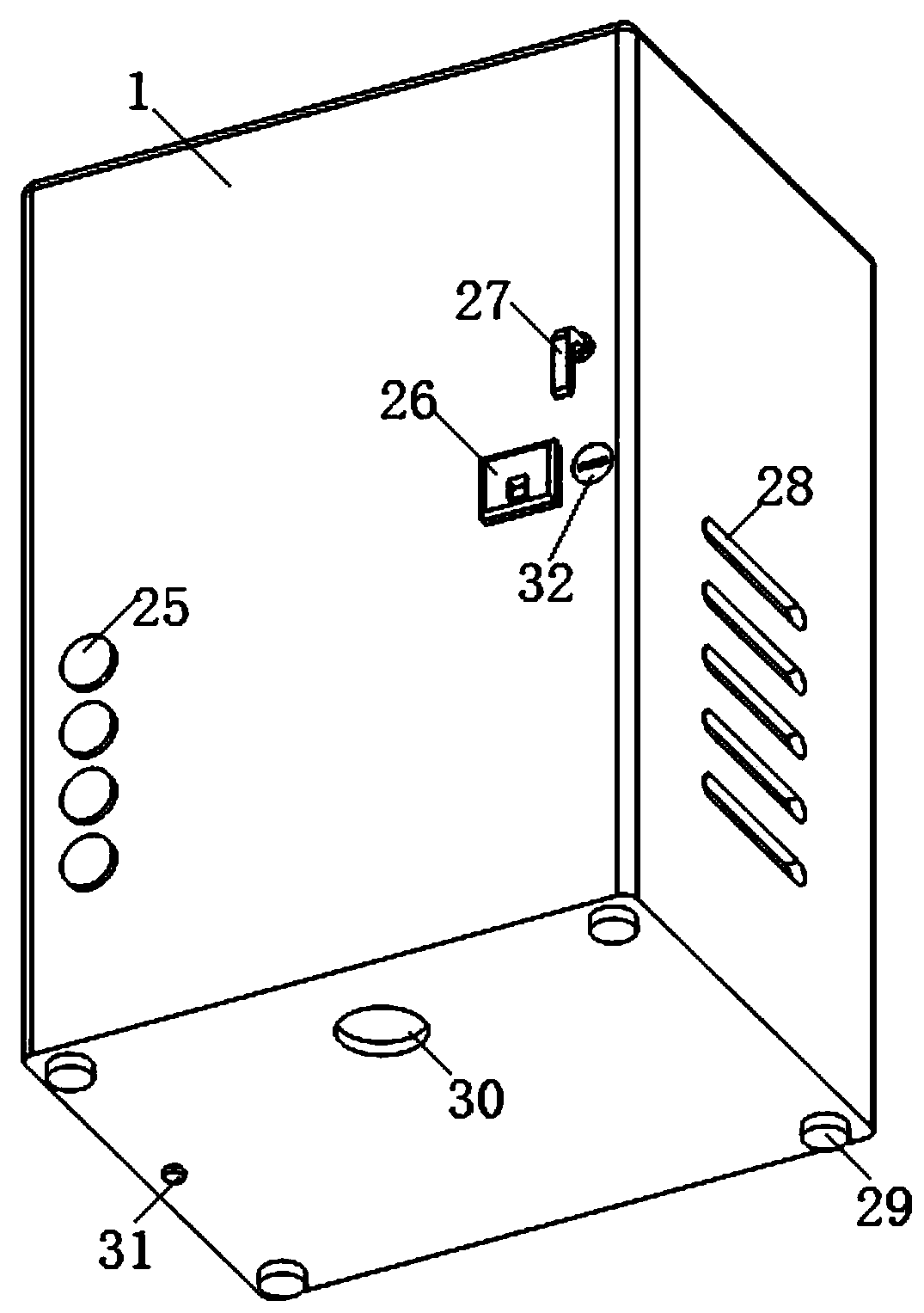

[0034] The device further includes a cabinet body 1; an installation partition 18 is installed in the middle of the interior of the cabinet body 1; a strut 2 is provided on the front side of the installation partition 18; A wiring device 3 is provided on the side; the terminal of the wiring device 3 is connected to a cable a4; the other end of the cable a4 is connected to a collection unit 5; the lower side of the collection unit 5 is provided with a bypass Control unit 7; a cable b6 is provided between the bypass control unit 7 and the acquisition unit 5; a cable c8 is connected to the lower part of the bypass control unit 7; the other end of the cable c8 is connected to There is a power-saving device body 9; one side of the acquisition unit 5 is provided with an integrated control unit 10; the integrated control unit 10 includes a control chip 11; the lower side of the integrated control unit 10 is equipped with a safety protection device 12. A surge control device 20 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com