Miniature high precision angle sensor

An angle sensor and high-precision technology, which is applied in the direction of transmitting sensing components with electric/magnetic devices, can solve problems such as the inability to meet the high-precision guidance requirements of missiles, and achieve the effects of light weight, safe use, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

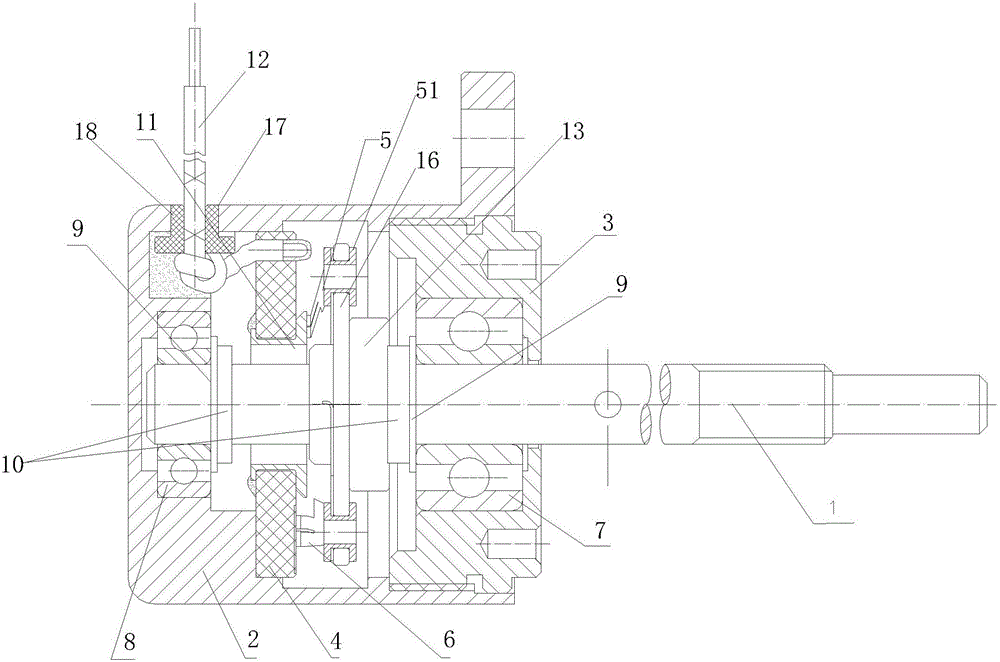

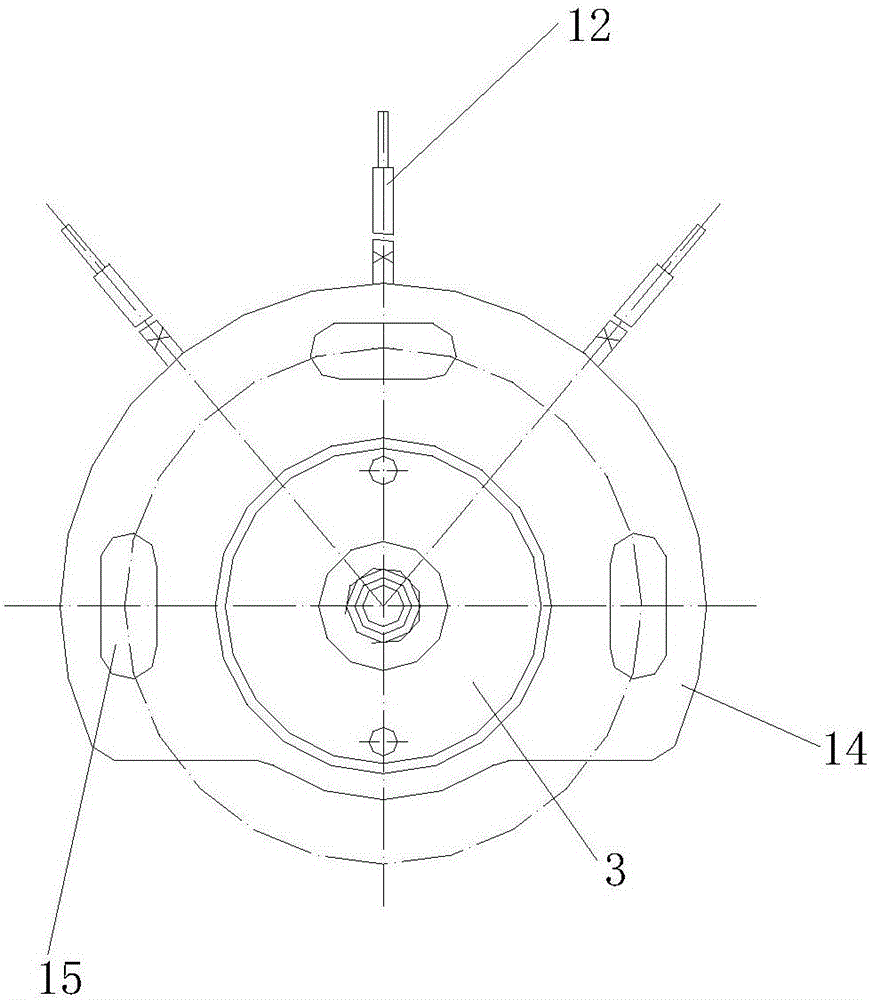

[0017] see Figure 1-4 As shown, a miniature high-precision angle sensor, including:

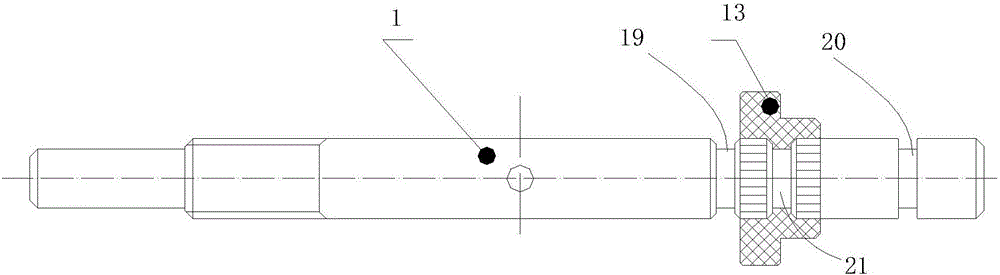

[0018] The casing 2, the rotating shaft 1 and the end cover 3 connected with the casing 2, the first bearing 7 and the second bearing 8 are installed inside the casing, the rotating shaft 1 extends into the casing 1 through the end cover 3 and is connected with the The first bearing 7 and the second bearing 8 are rotationally connected, and the first brush 5 and the second brush 6 are installed on the rotating shaft between the first bearing 7 and the second bearing 8 through a connecting piece. Between a brush 5 and the second brush 6 and the second bearing 8, a resistor body 4 is installed on the rotating shaft through a conductive rivet 11, and the first brush 5 and the second brush 6 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com