Bearing and manufacturing method thereof

A bearing and integrated technology, applied in bearings, bearing components, air-cushion bearings, etc., can solve the problems of poor structural stability, complex preparation process, low production efficiency, etc., and achieve high production efficiency, simple production and preparation process, and high production effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

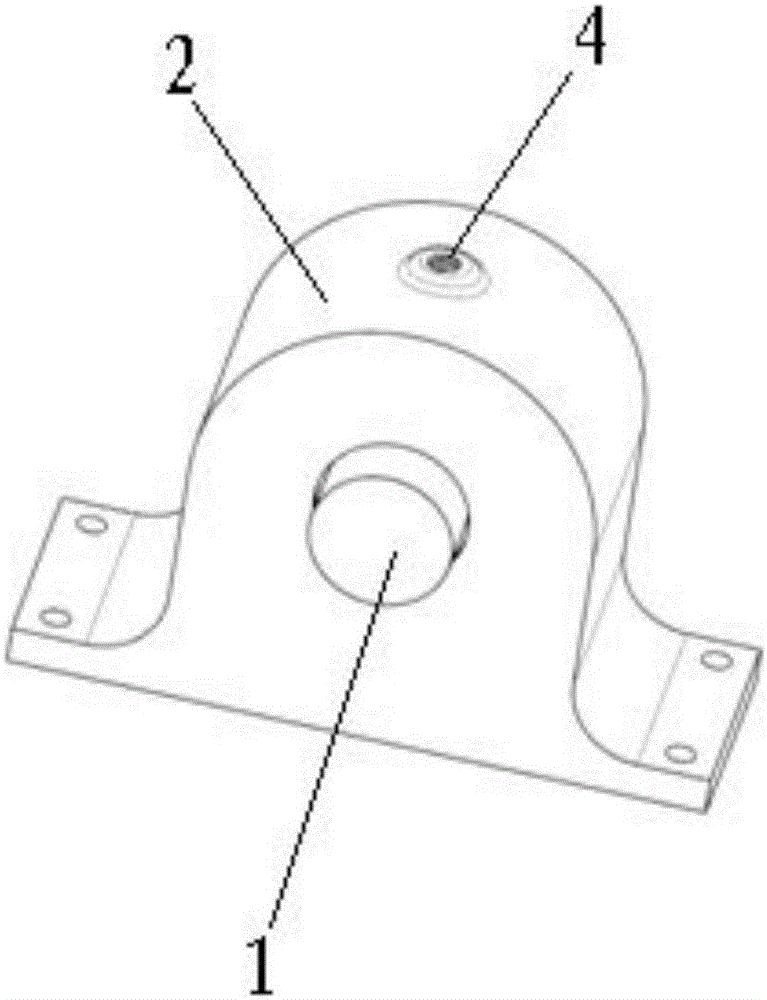

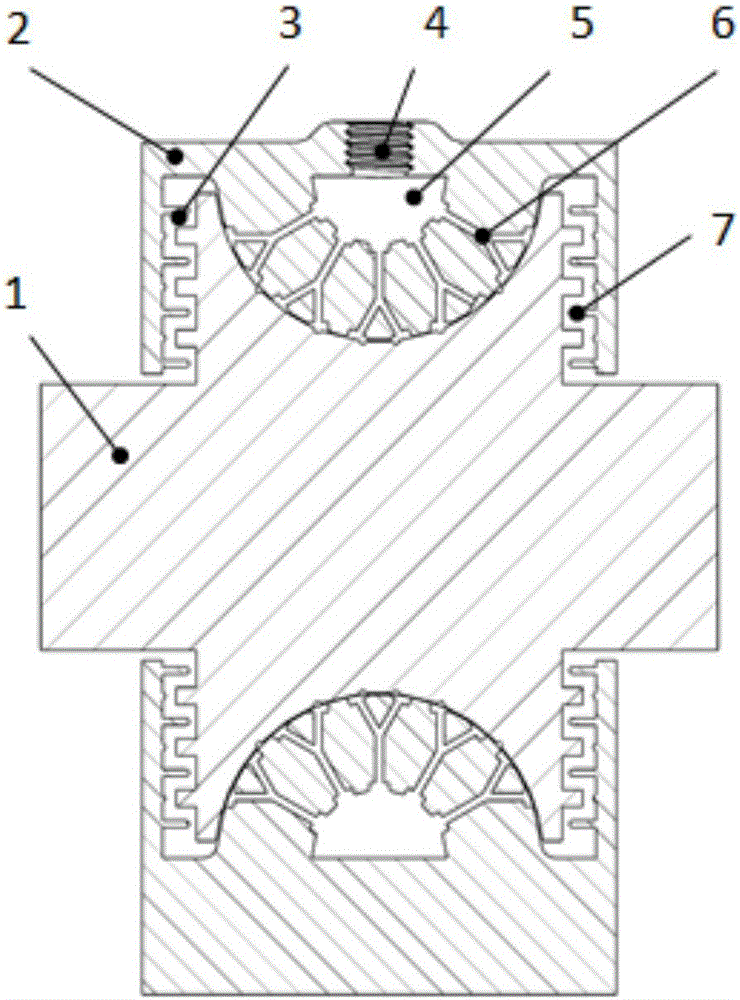

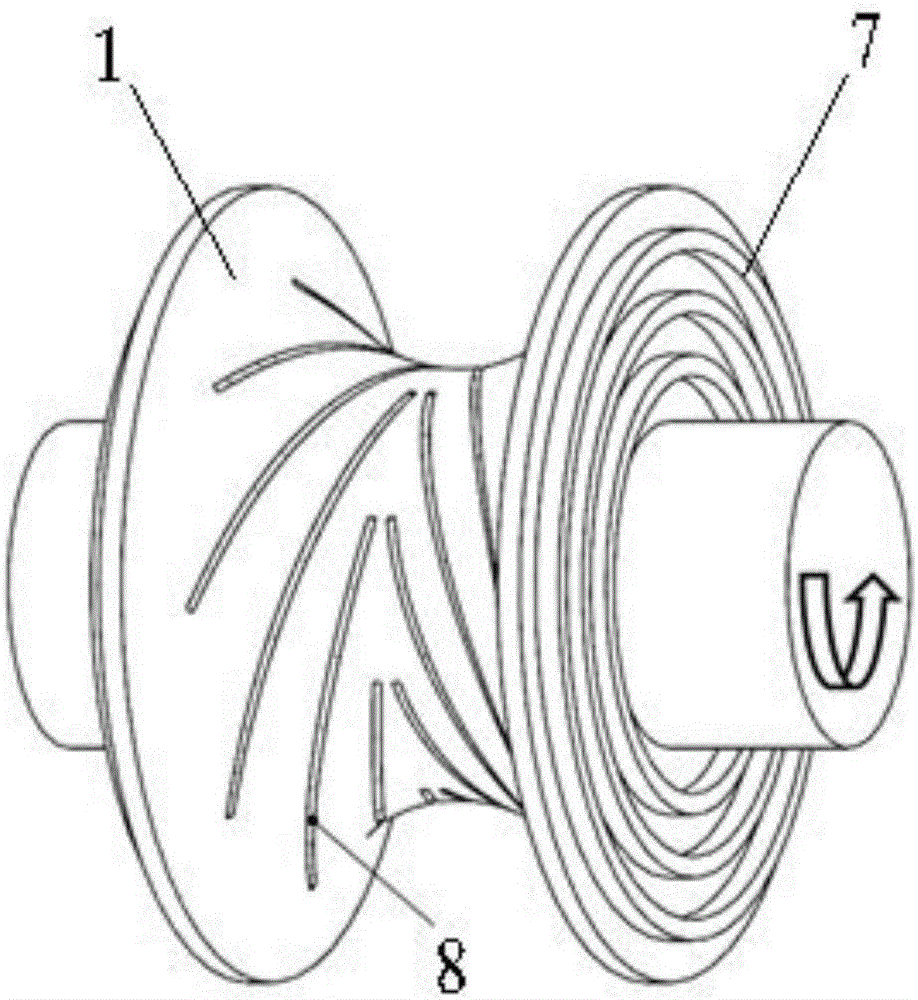

[0032] Such as Figure 1-4 As shown, a bearing includes a stator 2 and a rotor 1 arranged in the stator 2;

[0033] The inner wall of the stator 2 is provided with an annular protrusion along the circumferential direction, and the outer wall of the rotor 1 is provided with an annular groove matching the annular protrusion.

[0034] The bearing can be a hydrostatic bearing or a conventional oil-lubricated bearing. The rotor 1 has a structure with a large diameter at both ends and a small diameter in the middle, that is, an annular groove is set in the middle, and a matching annular protrusion is provided on the stator 2. This structure cannot be produced separately by the stator 2 and the rotor 1. The preparation method needs to be integrally formed. Preferably, the stator 2 and the rotor 1 are int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com