Engine carburetor liquid level control device

A liquid level height and control device technology, applied to carburetors, engine components, machines/engines, etc., can solve problems such as inaccurate octane number measurement results, hysteresis of the liquid level automatic control system, liquid level fluctuations, etc., to improve Reliability and sensitivity, control test hysteresis, effect of reducing regulation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

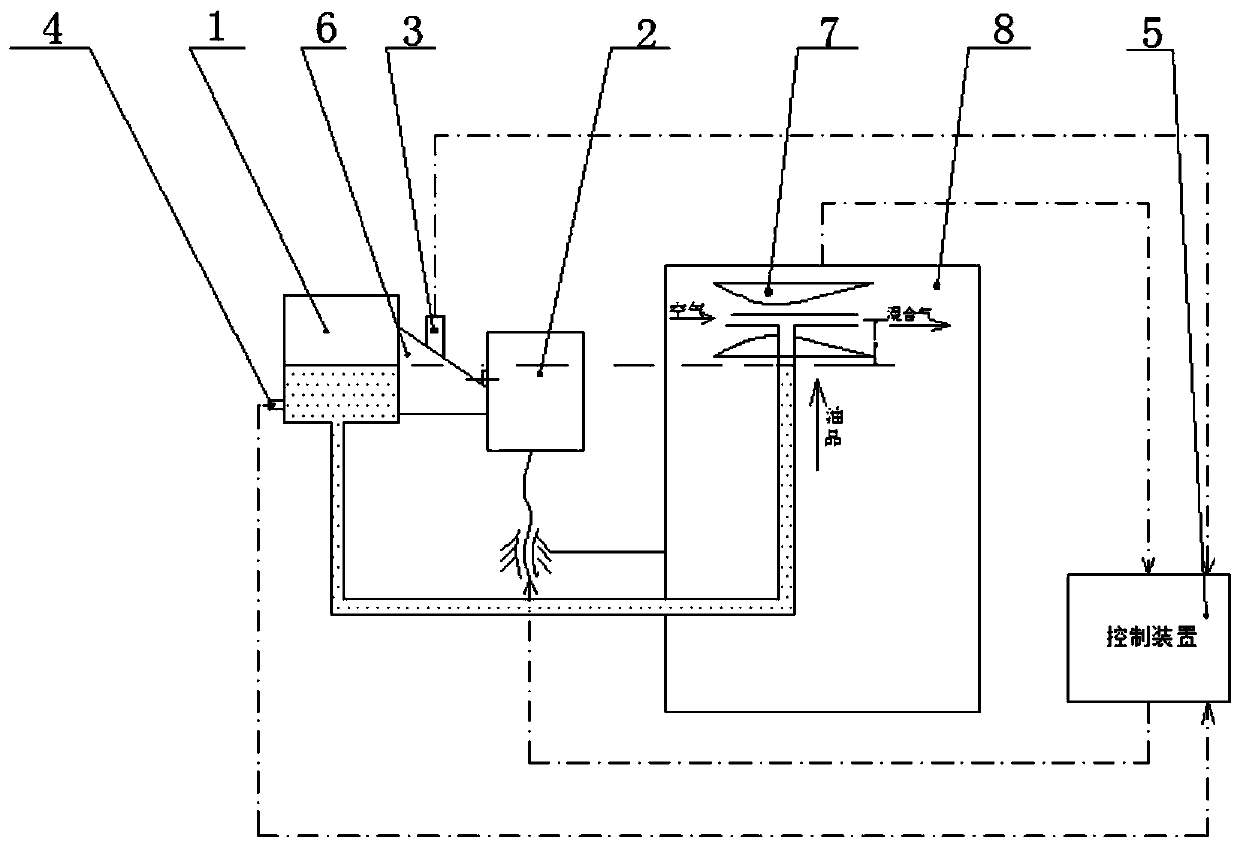

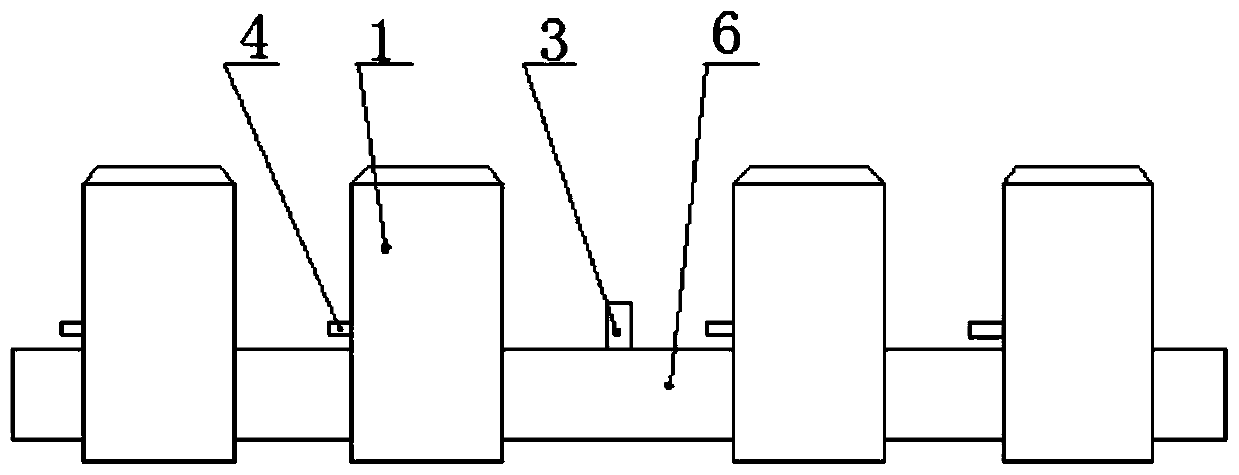

[0020] In this example, see figure 1 and figure 2 , an engine carburetor liquid level control device, which is combined and connected with the oil storage cup 1, and the oil storage cup 1 is connected with a hose to form a connector structure, mainly including a liquid level sensor 4, a displacement sensor 3, a control device 5, The lifting mechanism 2 and the oil storage cup support 6, the oil storage cup support 6 is fixedly connected with the oil storage cup 1, the motion output end of the movable part of the lifting mechanism 2 is fixedly connected with the oil storage cup support 6, and controlled by the control device 5, the The movable part of the lifting mechanism 2 can drive the oil storage cup 1 to perform a controllable lifting movement through the oil storage cup bracket 6. The fixed frame part of the lifting mechanism 2 is fixedly connected with the gasoline octane number measuring machine body, and the liquid level sensor 4 is arranged in the storage tank. On t...

Embodiment 2

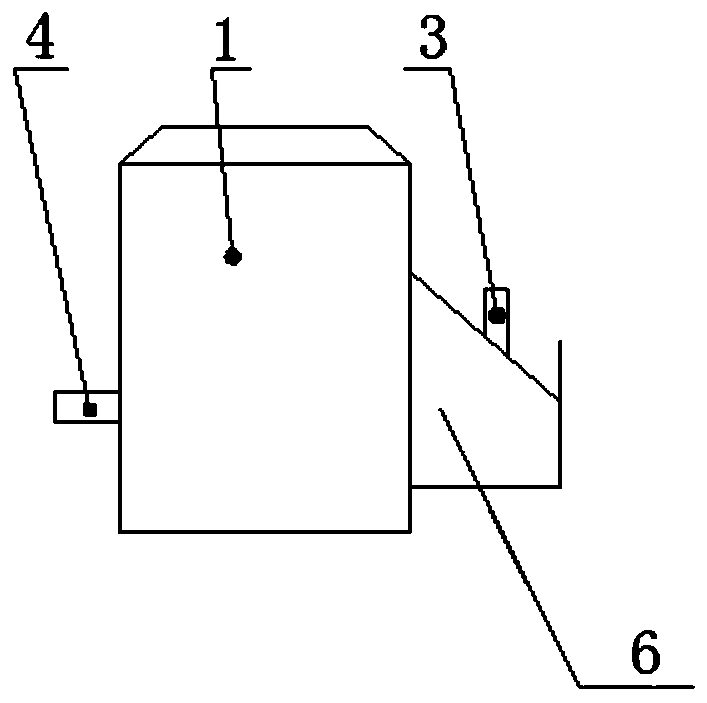

[0024] This embodiment is basically the same as Embodiment 1, especially in that:

[0025] In this example, see image 3 A single-oil oil storage device is composed of an oil storage cup 1 and an oil storage cup bracket 6, the oil storage cup 1 is connected with a single switch valve through a hose, and the oil storage cup bracket adopts a single oil product oil storage cup bracket. In this embodiment, one side of the lifter 2 is movably connected to the oil storage cup support 6, the other side of the lifting mechanism 2 is fixedly connected to the gasoline octane number measuring machine body, and the displacement sensor 3 and the liquid level sensor 4 are respectively connected to the oil storage cup holder. On the cup support 6 and the oil storage cup 1; the oil storage cup support 6 adopts a single oil product oil storage cup support, and the single oil product oil storage cup support is a structure equipped with an oil storage cup 1, and the oil storage cup 1 and a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com