Coiled material packaging mechanism and bundling device and application method and recovery method of coiled material bundling device

A packaging device and roll material technology, applied in the direction of packaging, transportation and packaging, containers with multiple items, etc., to achieve the effects of stable and safe clamping, convenient transportation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

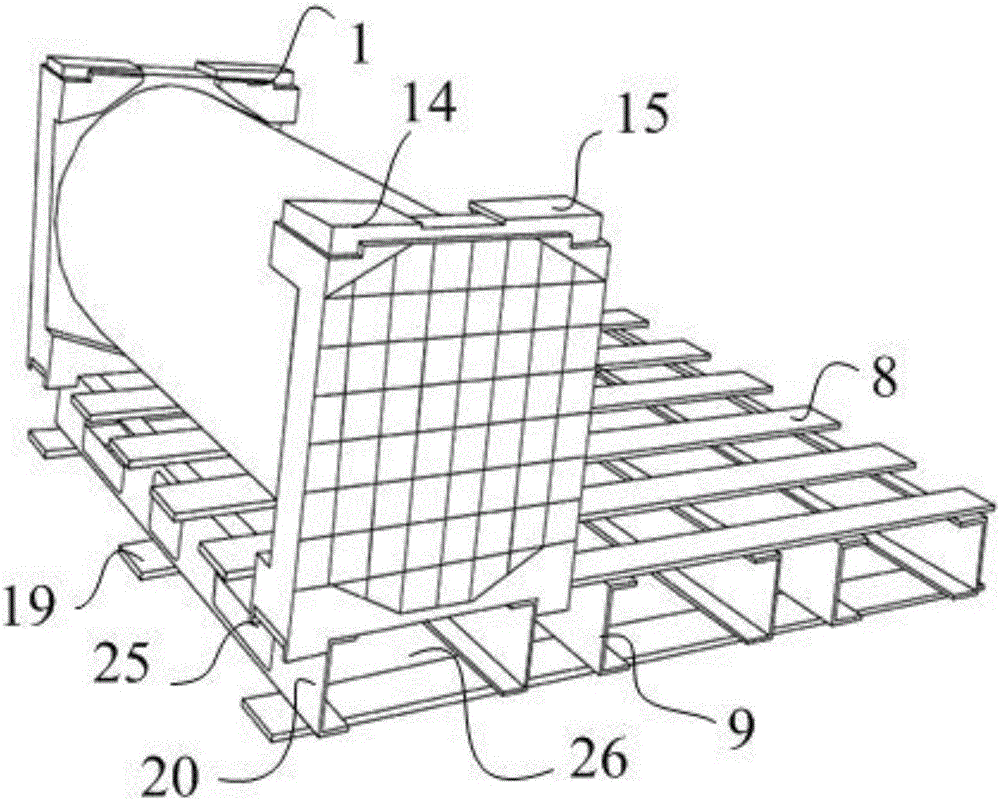

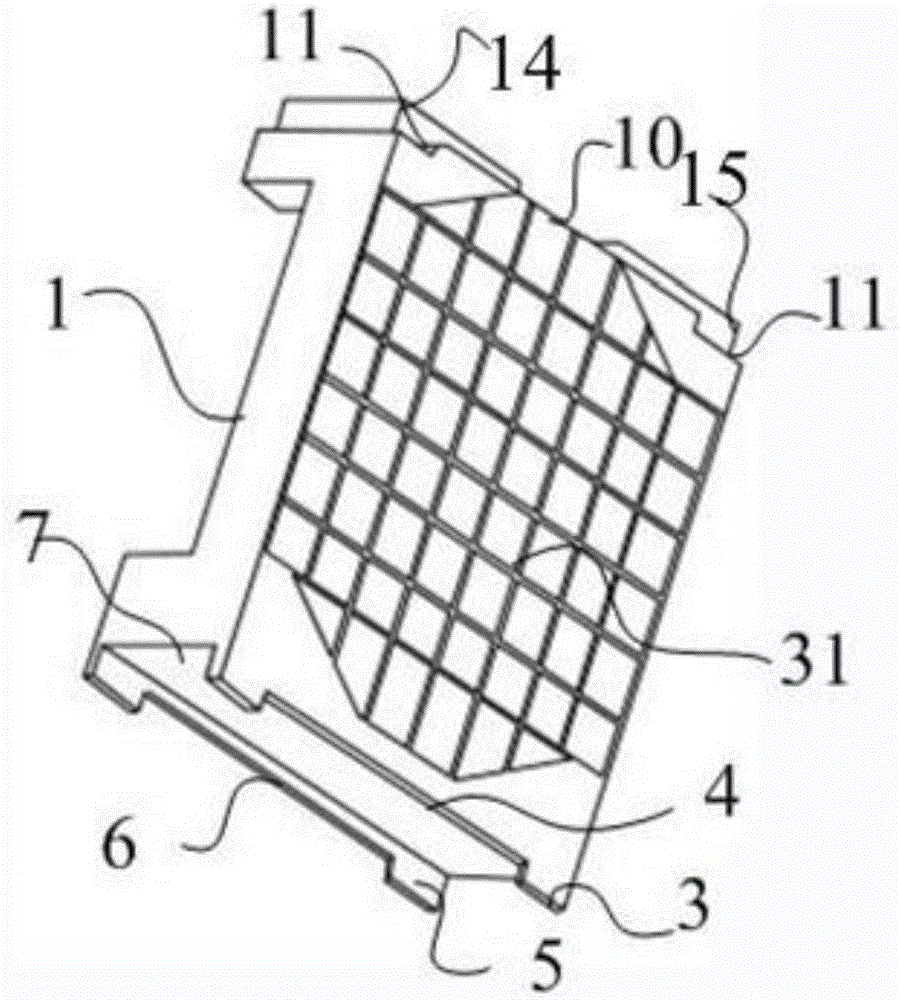

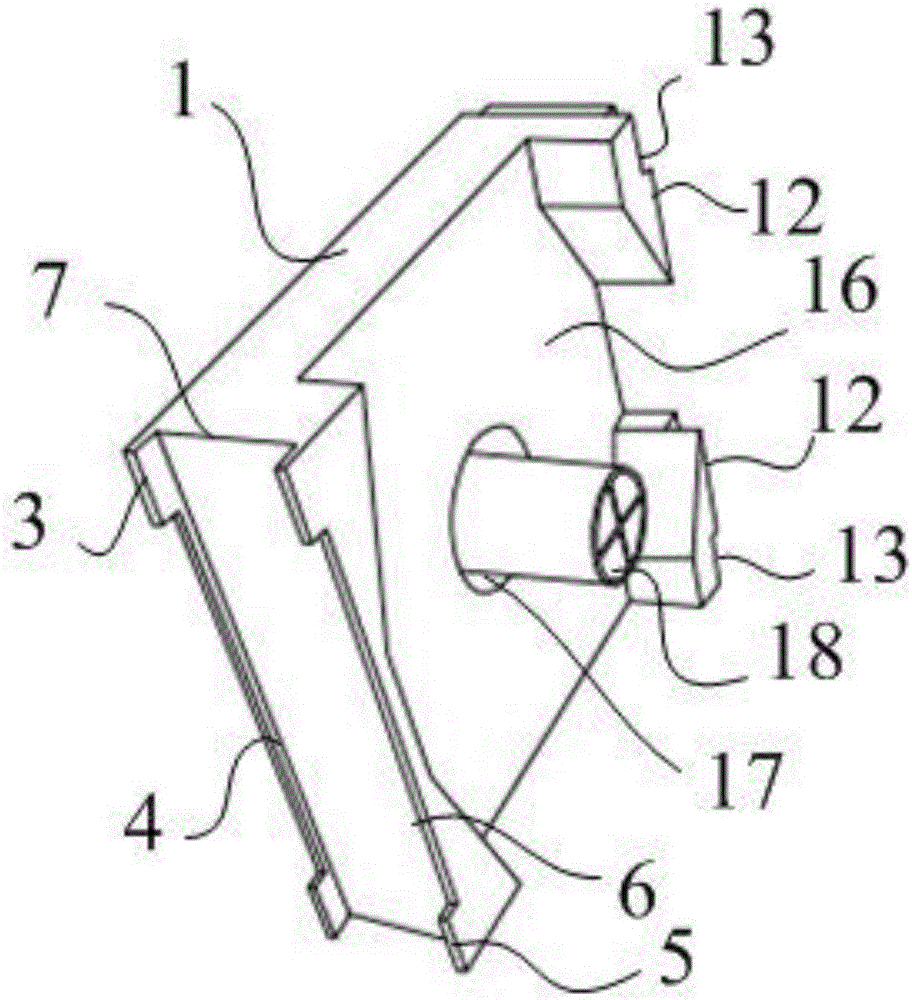

[0044] like Figure 1 to Figure 4 As shown, the present invention provides a coil packaging mechanism, including an end cover 1 suitable for clamping and fixing the coil from the shaft end of the winding shaft of the coil, and a tray 2 suitable for supporting the end cover 1 from the bottom surface wherein the bottom of the end cover 1 is provided with a saddle base relative to the front end of the end cover 1; the saddle base includes front and rear saddles which are integrally constructed with the front and rear end faces of the end cover respectively and mirrored; The front saddle includes left and right front wings 3 and a front slot 4 between the left and right front wings 3, and the rear saddle includes left and right rear wings mirrored with the left and right front wings 3. The wing 5, and the rear draw-in slot 6 mirrored with the front draw-in slot 4, that is, the front draw-in slot 4 and the rear draw-in slot 6 jointly constitute the draw-in slot of the saddle base; ...

Embodiment 2

[0055] like Figure 5 to Figure 9 As shown, on the basis of Embodiment 1, the present invention also provides a coil packaging device, including the tray 2 and a clamping assembly composed of several coil clamping units stacked vertically; The clamping assembly is placed side by side on the upper end surface of the tray; wherein the coil clamping unit includes a coil and two end caps 1 that respectively clamp and fix the coil from the shaft end of the winding shaft of the coil ;By engaging the front and rear saddles of the end cover of one coil clamping unit with the front and rear saddles of the end cover of another coil clamping unit, and the end cover 1 of the coil clamping unit The left and right wing saddles of the other coil clamping unit are respectively engaged with the left and right saddle wing seats 7 of the end cover, so that the top of the end cover of the one coil clamping unit is in contact with the The bottom of the end cover 1 of the other coil clamping unit ...

Embodiment 3

[0063] like Figure 10 As shown, on the basis of Embodiment 2, the present invention also provides the use method and recycling method of the coil packing device, the use method of the coil packing device includes the following steps:

[0064] In step S1, one of the end caps 1 is placed on the two shaft ends of the winding shaft of the coiled material to form a coiled material clamping unit;

[0065] Step S2, stacking several coil clamping units vertically to form a clamping assembly;

[0066] Step S3, placing several clamping components horizontally side by side on the upper end surface of the tray 2, through the bottom end surface of the bottom end cover 1 of the clamping component, it is engaged with the pallet 2, and the clamping component is supported from the bottom surface ;

[0067] Step S4, set the end cap 34 on the top end surface jointly formed by the upper end surfaces of the plurality of clamping components, suitable for fixing the clamping component from the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com