EVA cold/hot forming machine and forming method of cold/hot forming machine

A thermoforming machine and cold forming machine technology, applied in the field of plastic molding equipment, can solve the problems of large equipment footprint, high equipment cost, and low manufacturing cost, and achieve small footprint, simple and compact structure, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

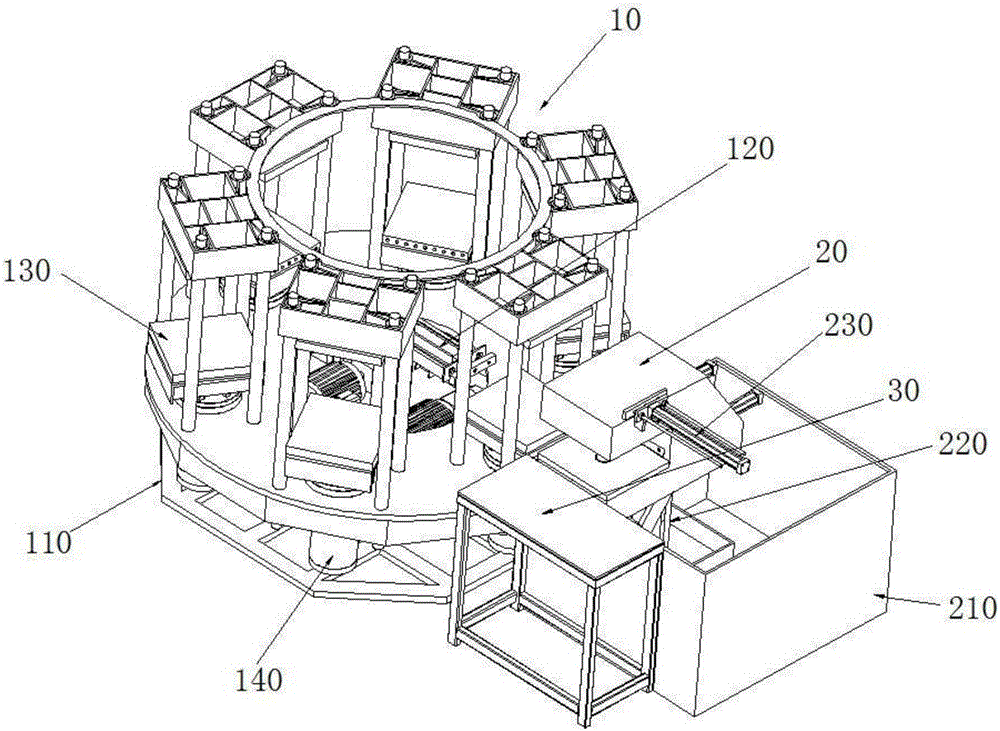

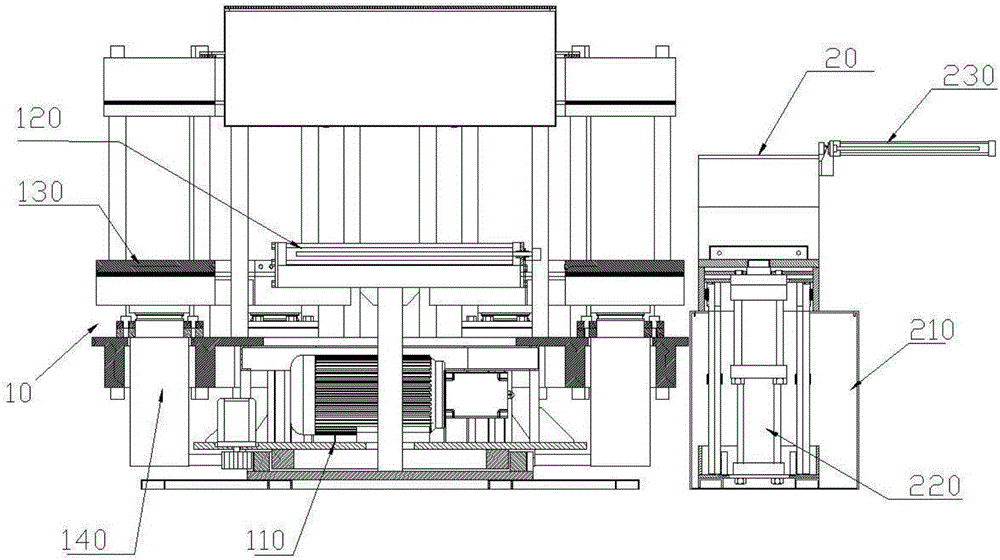

[0041] Please refer to figure 1 and figure 2 , the EVA hot and cold molding machine provided in this embodiment includes a thermoforming machine 10 for heating the mould, and a cold molding machine 20 for cooling the mould. The thermoforming machine 10 includes a rotating base 110 capable of 360° intermittent rotation. There are n stations on the base 110, n≥2, each station is provided with a heating element 130 and a first hydraulic cylinder 140 for driving the heating element 130 to reciprocate in the vertical direction, and the center of the rotating base 110 is provided with The first mold pushing mechanism 120 , the movable end of the first mold pushing mechanism 120 is aligned with the position where the mold is placed on the first station, and is used to push the heated mold to the cold forming machine 20 . The cold forming machine 20 includes a coolant tank 210 and a lift mechanism 220 arranged in the coolant tank 210. The lift mechanism 220 is close to the first sta...

Embodiment 2

[0043] Please refer to figure 1 and figure 2 , the present embodiment is further provided with a third mold pushing mechanism on the lifting mechanism 220, the third mold pushing mechanism is perpendicular to the moving direction of the second mold pushing mechanism 230, and the third mold pushing mechanism is used to lift the cooled mold from the lifting mechanism 220 roll out. The moving directions of the second mold pushing mechanism 230 and the third mold pushing mechanism are vertical, and the stretching time of the movable ends is one in front and one in back without interfering with each other.

Embodiment 3

[0045] Please refer to figure 1 and figure 2, the EVA hot and cold forming machine provided in this embodiment also includes a workbench 30, the EVA cold and hot forming machine includes a thermoforming machine 10, a cold forming machine 20 and a workbench 30, and the mold to be heated is pushed from the workbench to the lifting mechanism 220, the mold after cooling is pushed out from the lifting mechanism 220 to the workbench 230, as long as one worker stands next to the fixed workbench during the entire cold and hot forming process, the operation of multiple stations can be completed without walking around, and the working environment is relatively safe. Personal danger is avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com