4+6 spindle combined type special multi-spindle drilling machine for riser bus bar groups of aluminum electrolysis cells

A technology of aluminum electrolytic cell and multi-axis drilling machine, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc. Occupancy and other problems, to achieve the effect of reducing equipment complexity, reducing intermediate driving links, and reducing equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is a further description of the "4+6" shaft combined special multi-axis drilling machine for the aluminum electrolytic cell column busbar group of the present invention in combination with the accompanying drawings and specific implementation methods:

[0037] like figure 1 As shown, each group of upright busbars includes A-type upright busbar 01, B-type upright busbar 02, A-type splint busbar 03, B-type splint busbar 04, short-circuit busbar 05, and short-circuit busbar 06.

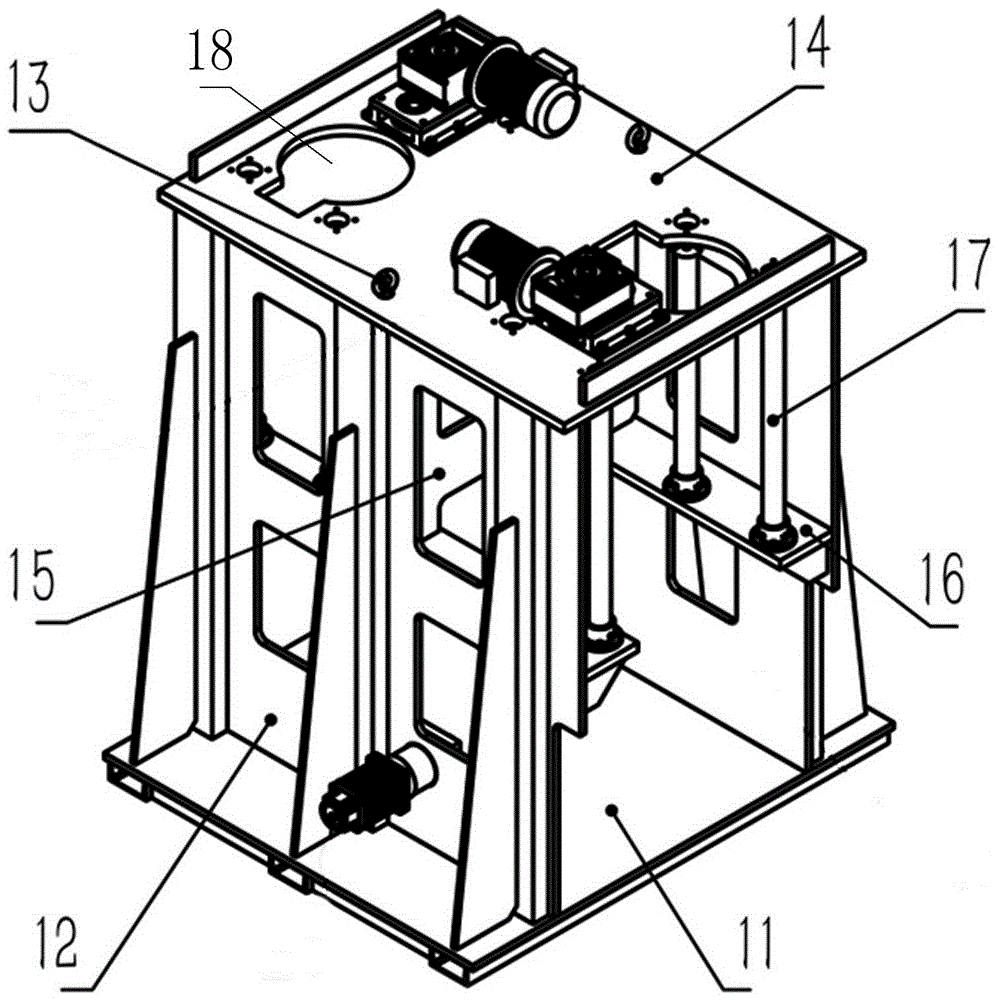

[0038] like Figure 2-11 As shown, a special multi-axis drilling machine with "4+6" axis combination type of aluminum electrolytic cell column busbar group includes a portal frame 1, a gearbox support 7, a four-axis gearbox 2 and a six-axis gearbox 3. The frame 1 includes a bottom plate 11, a top plate 14 and side vertical plates 12 on both sides. The bottom of the bottom plate 11 is provided with a bottom channel steel group, and the bottom plate 11 and the bottom channel steel gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com