In-situ detection device and detection method of free-form surface optical element

A technology of optical components and detection devices, which is applied in the field of ultra-precision detection of complex curved surfaces, can solve problems such as indistinguishable, overlapping error forms and processing errors, dynamic tracking errors, etc., and achieve the effect of compact structure, strong versatility, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

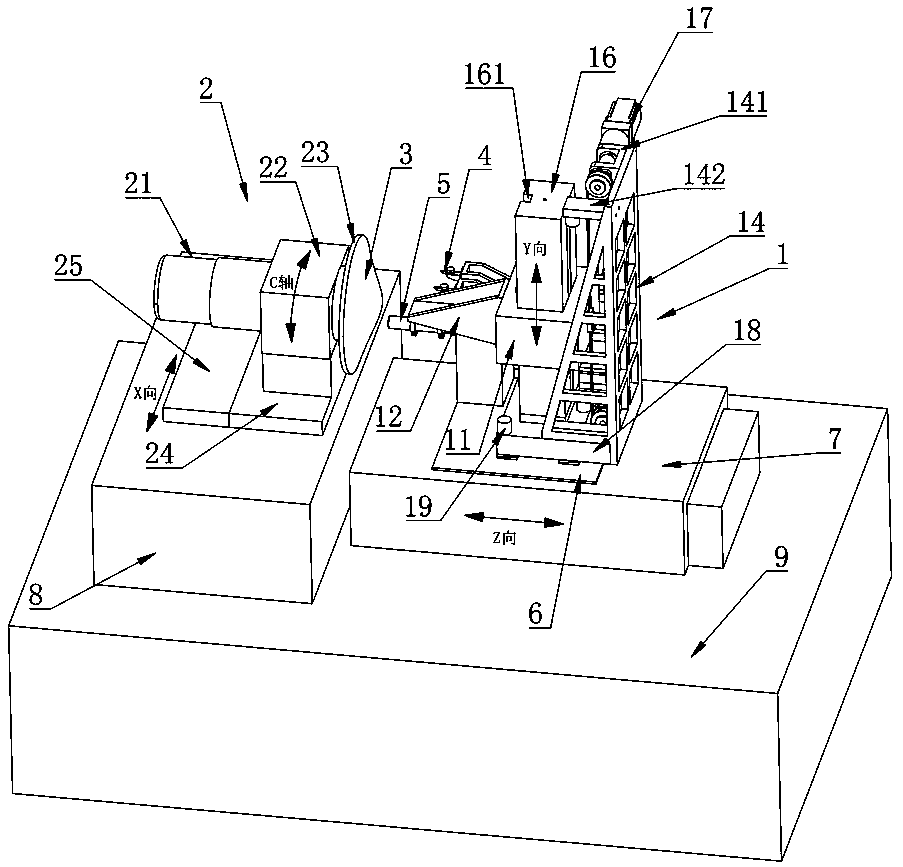

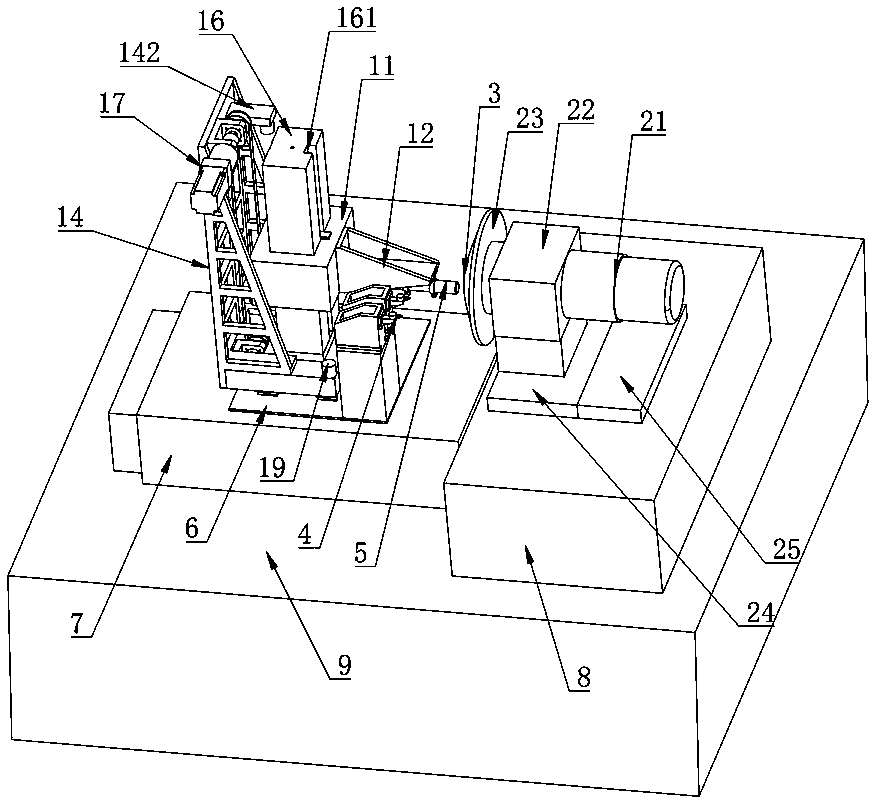

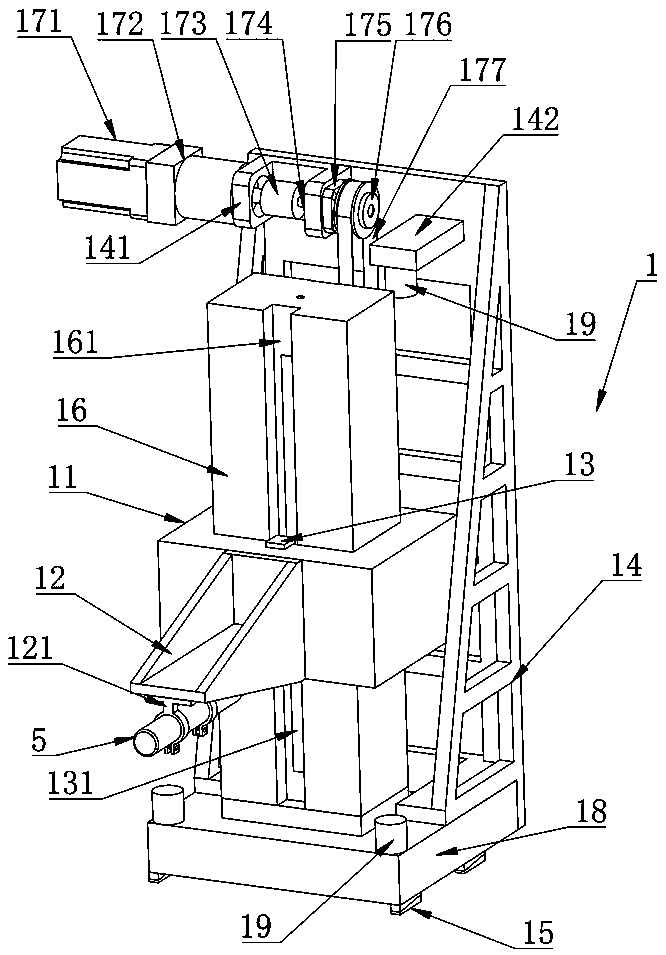

[0037] Such as Figures 1 to 8 As shown, an in-position detection device for a free-form surface optical element of the present invention includes a rotating main shaft 2, a Z axis 7, an X axis 8, and a Y-axis module 1 vertically arranged above the Z axis 7, and the rotating main shaft 2 is arranged horizontally Above the X-axis 8 and parallel to the Z-axis 7, the free-form surface optical element 3 is clamped on the rotating spindle 2. The Y-axis module 1 includes a slider 11 and a column 16. The slider 11 is slid on the column 16. The slider 11 is provided with a displacement sensor 5 for in-situ measurement of the free-form surface optical element 3 . The Y-axis module 1 vertically arranged above the Z-axis 7 forms three linear axes with the X-axis 8 and Z-axis 7 to realize spatial movement. The Y-axis module 1 includes a slider 11, a colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com