Shale gas wastewater treatment method and system

A waste water treatment system, waste water treatment technology, applied in the direction of mining waste water treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve difficult problems such as cleaning up and meeting discharge or reuse standards, and achieve Significant environmental protection effect and economic benefits, the effect of reducing the concentration of flocs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

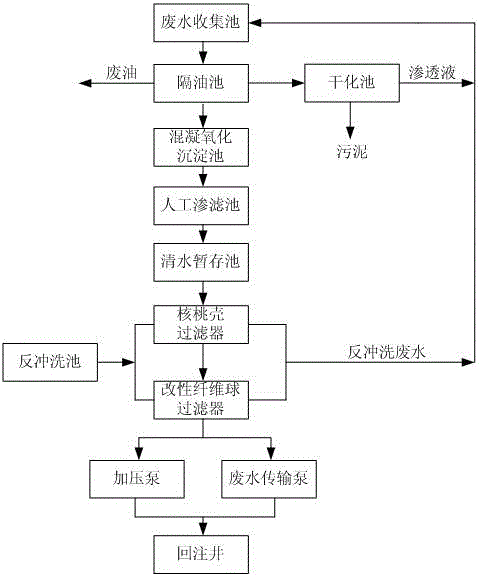

[0019] figure 1 A schematic diagram of a specific embodiment of the shale gas wastewater treatment system of the present invention is given.

[0020] figure 1 In this method, the shale gas mining wastewater to be treated is pre-stored in a wastewater collection tank, and the wastewater is introduced from the wastewater collection tank into the grease trap for oil-water separation. Due to the different densities of water and oil, the oil density is lighter on the liquid surface, and the water density The larger is located in the lower layer of the liquid surface, and the water and oil can be separated by water and oil stratification. The separated waste oil can be recycled and sent to the refinery as raw material, and the sewage after oil and water separation enters the next step.

[0021] In the coagulation oxidation sedimentation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com