Circuit board mounting and fastening method

A circuit board and fastening technology, applied in the field of circuit board installation and fastening, can solve the problems of low installation efficiency, inconvenient operation, and a large number of connecting screws, and achieve high installation reliability, reduce installation costs, and improve installation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

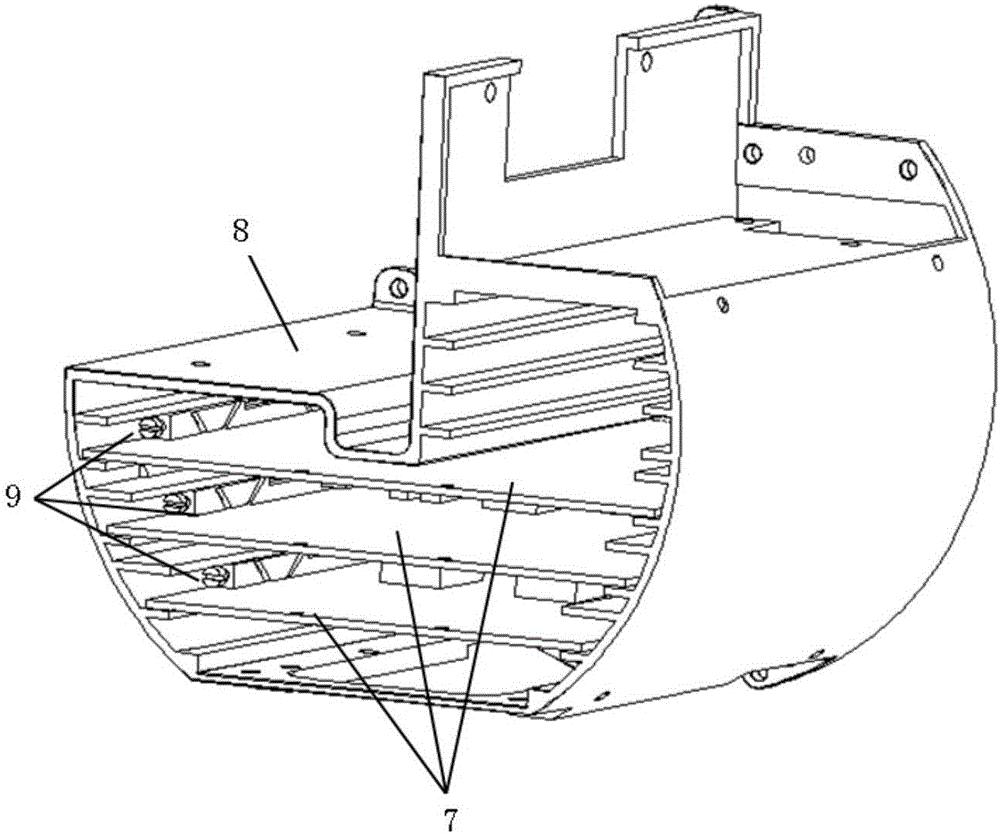

[0044] 1. Design and make locking strip 9

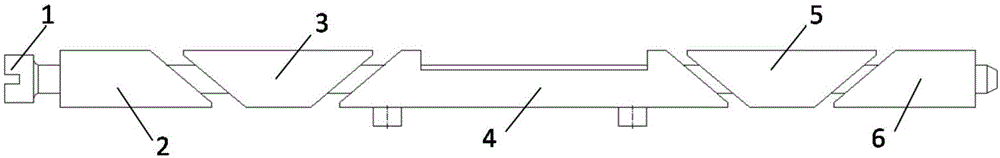

[0045] The locking bar includes screw 1, fixed block 1, movable block 1, fixed mounting block 4, movable block 5, fixed block 2, 6. Screw 1 is a long threaded rod with external threads.

[0046] The fixed block one 2 is a wedge-shaped structure with a right-angled trapezoid in cross section. The wedge angle of the inclined surface is 30°, and a circular through hole is provided on the rectangular side

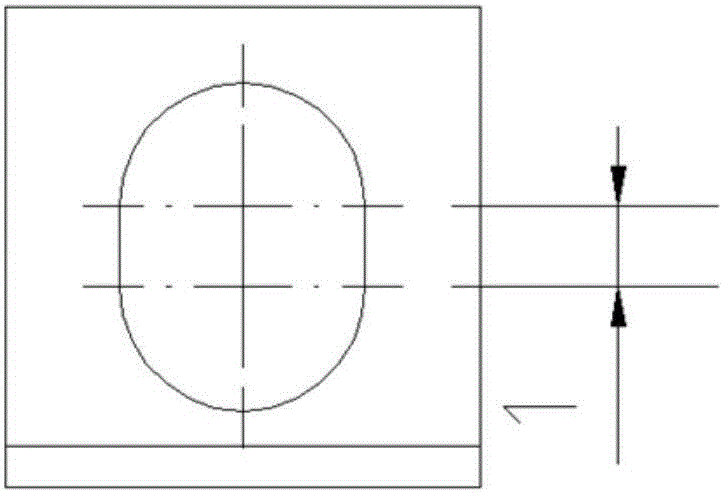

[0047] The movable block 3 is a wedge-shaped structure with an inverted trapezoid in section. The wedge angle of the inclined surface is 30°, which is consistent with the inclined wedge angle of the fixed block 2. The inclined surfaces of the movable block 3 and the fixed block 2 are parallel to each other. 3 center set up The waist-shaped hole, the center distance is 1mm, such as image 3 Shown

[0048] The movable block two 5 and the movable block one 3 belong to the same parts and have the same structural characteristics;

[0049] The fi...

Embodiment 2

[0057] 1 Design and make the locking strip 9

[0058] The locking bar includes screw 1, fixed block 1, movable block 1, fixed mounting block 4, movable block 5, fixed block 2, 6. Screw 1 is a long threaded rod with external threads.

[0059] The fixed block one 2 is a wedge-shaped structure with a right-angled trapezoid in cross section. The wedge angle of the inclined surface is 20°, and a circular through hole is provided on the side of the rectangle.

[0060] The movable block 3 is a wedge-shaped structure with an inverted trapezoid in cross section. The wedge angle of the inclined surface is 20°, which is consistent with the inclined wedge angle of the fixed block 2. The inclined surfaces of the movable block 3 and the fixed block 2 are parallel to each other. 3 center set up The waist-shaped hole, the center distance is 1mm, such as image 3 Shown

[0061] The movable block two 5 and the movable block one 3 belong to the same parts and have the same structural characteristics;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com