Efficiency optimizing control method for permanent magnet motor

A technology of permanent magnet motor and control method, which is applied in the direction of motor control, single motor speed/torque control, control system, etc., can solve the problems of increasing costs, reduce hardware circuit costs, improve product competitiveness, and be easy to implement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

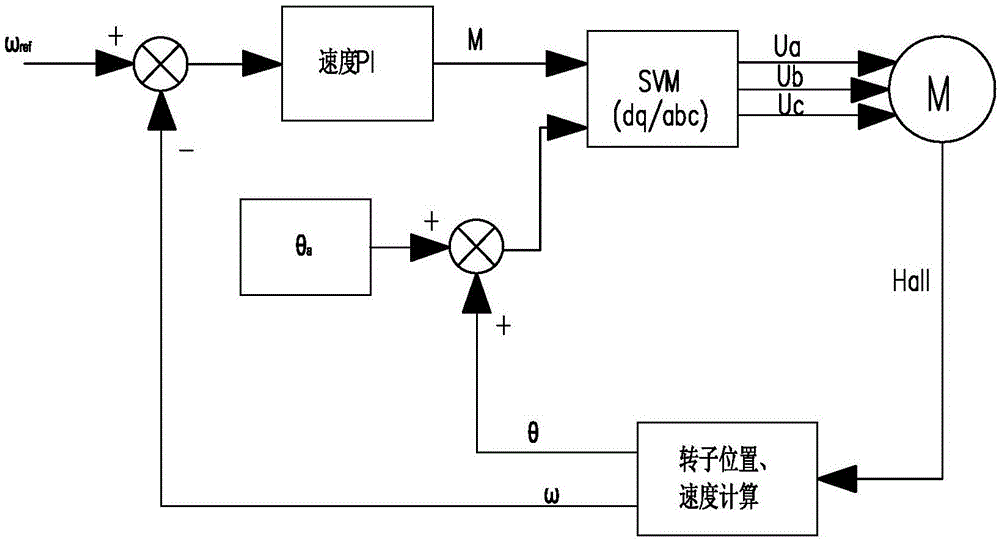

[0016] Such as figure 2 Shown, is the efficiency optimization control method of a kind of permanent magnet motor of the present invention, comprises the following steps:

[0017] (A) The Hall position signal of the motor rotor collected by the MCU through the capture port;

[0018] (B) Calculate the rotation speed ω of the motor and the angle θ of the rotor according to the Hall position signal;

[0019] (C) Set the given speed ω ref The difference between the motor's real-time rotation speed ω is calculated by the speed PI loop to generate the modulation ratio M of the sine wave;

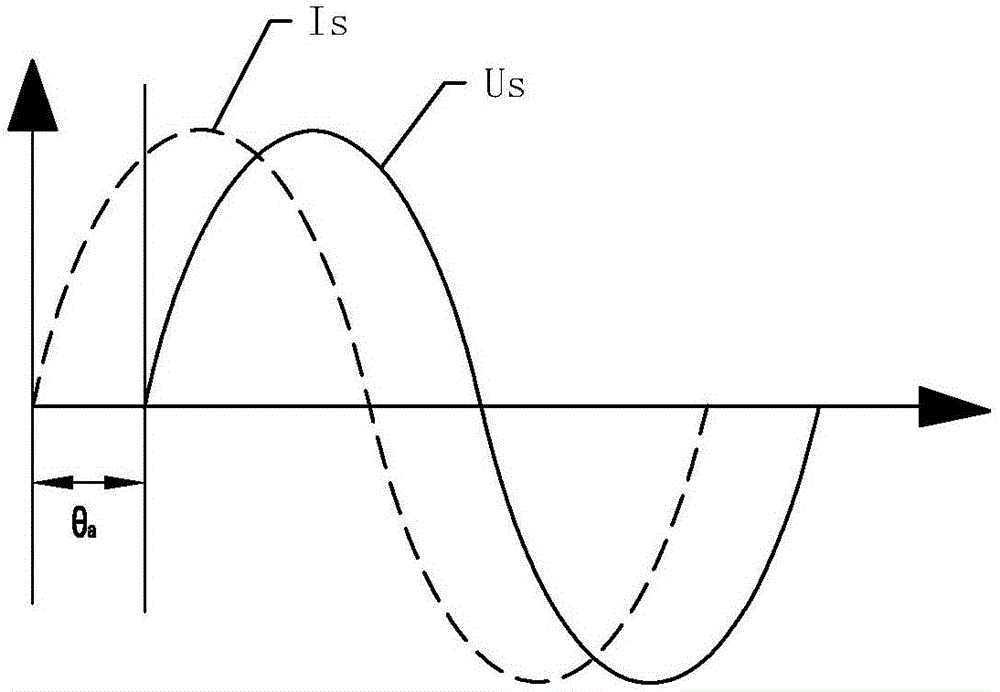

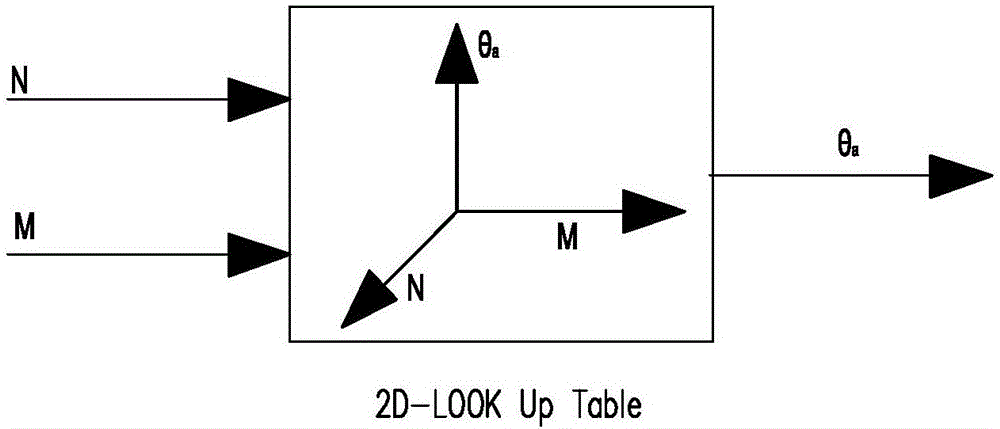

[0020] (D) Obtain the leading angle θ of the current vector lagging behind the voltage vector a ;

[0021] (E) Add the real-time angle θ of the rotor to the lead angle θ a Afterwards, SVM space vector modulation is carried out with the modulation ratio M of the sine wave to generate the sine wave drive signals Ua, Ub, and Uc required by the motor;

[0022] (F) Apply sine wave drive signals U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com