Press-connection mechanism

A pivotal connection and pivotal point technology, applied in the field of wire harness processing equipment, can solve the problems of terminal deviation, large clamping force, terminal clamping damage, etc., and achieve the effect of convenient use, simple structure and appropriate clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

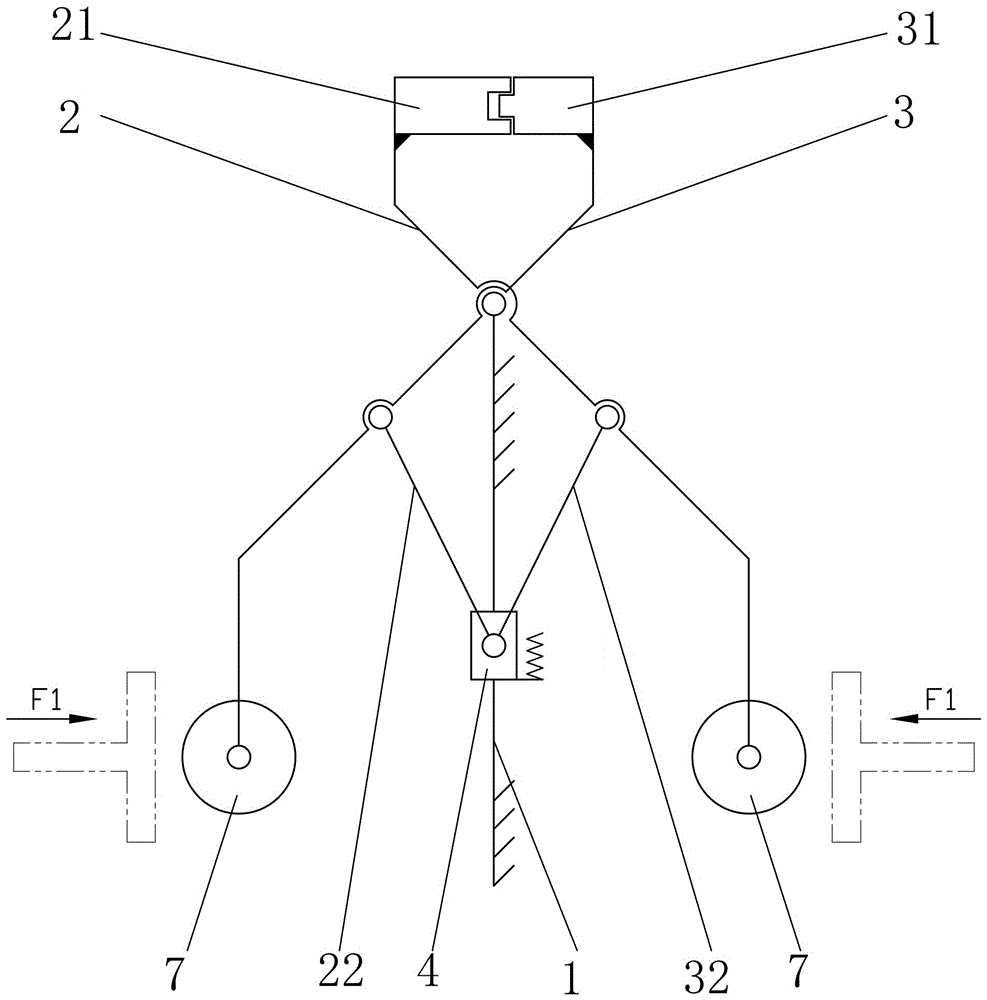

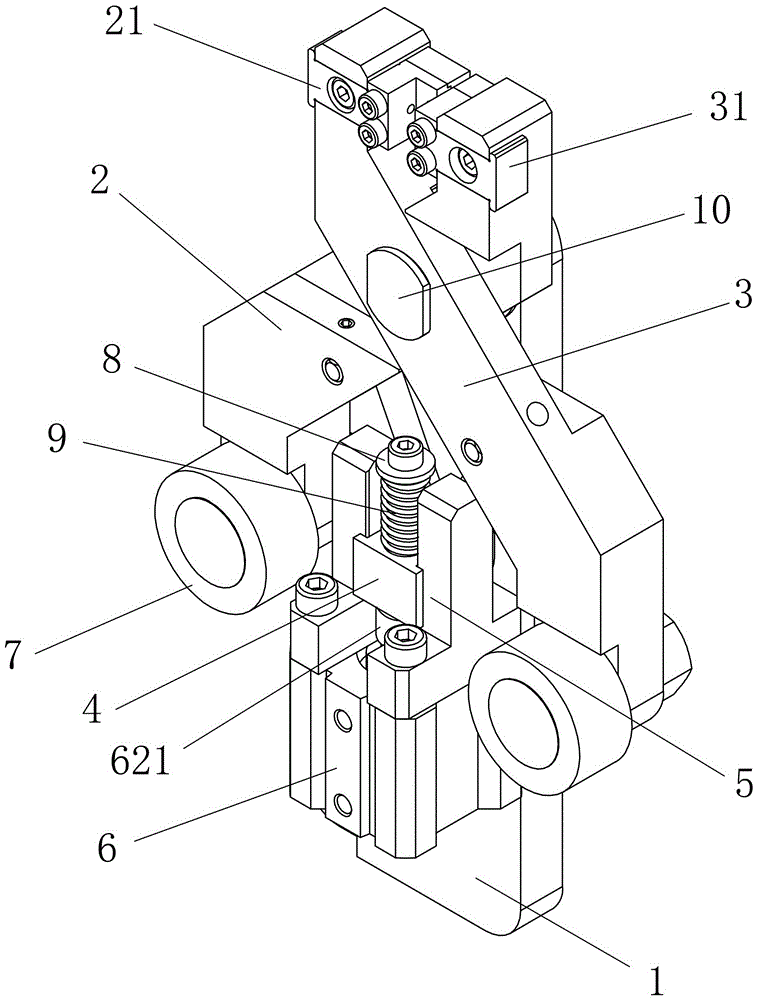

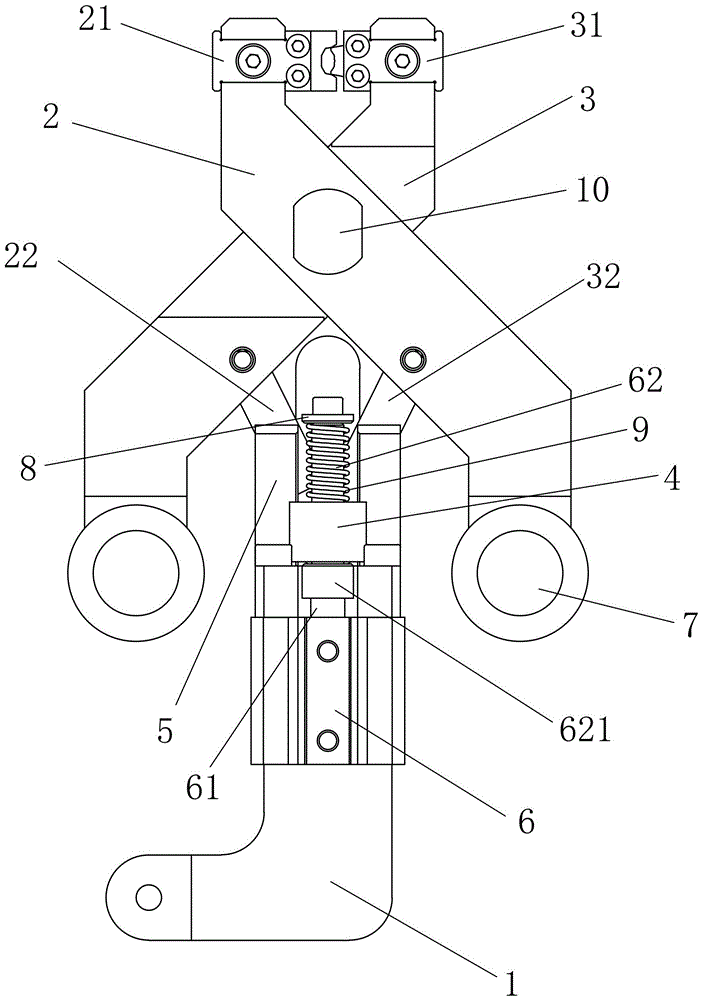

[0015] see figure 1 , figure 2 and image 3 , the present invention relates to a crimping mechanism, and its preferred embodiment includes a frame 1, on which a first crimping arm 2 and a second crimping arm 3 pivotally connected in the middle are arranged, the first crimping arm The middle parts of the arm 2 and the second crimping arm 3 are pivotally connected to each other through a pivot 10, and the pivot 10 is pivotally connected with the lock block (not shown) on the frame 1; the upper end of the first crimping arm 2 is bolted The die 21 is fixed, the upper end of the second crimping arm 3 is fixed with a punch 31 with bolts, the first crimping arm 2 is pivotally connected with the first connecting rod 22 between the end and the middle hinge point, and the second crimping arm 3 A second connecting rod 32 is pivotally connected between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com