Formation clamp machine for bilateral-tab polymer soft-package power battery

A technology of power battery and soft pack battery, which is applied in the field of double-sided tab polymer soft pack power battery forming fixture machine, can solve the problems of long time period, high ambient temperature, high battery defect rate, and achieve uniformity and thermal uniformity. performance guarantee, pressure accuracy and reliability improvement, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

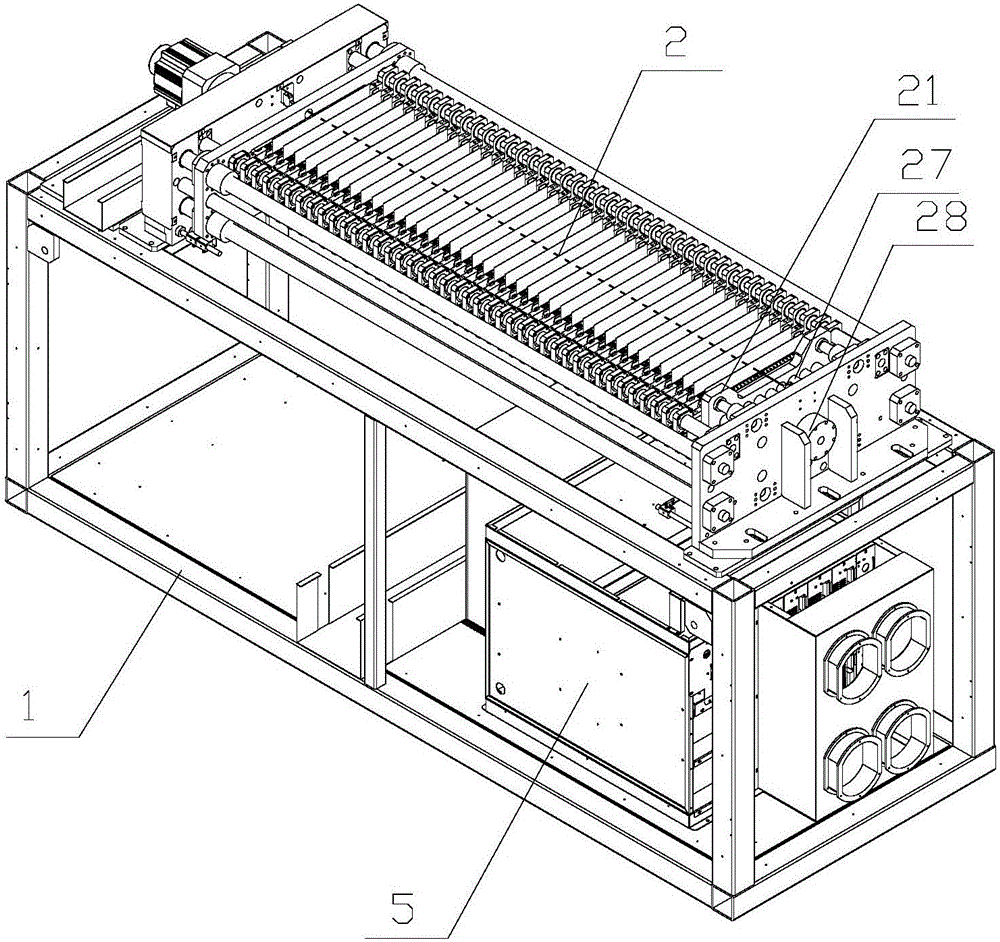

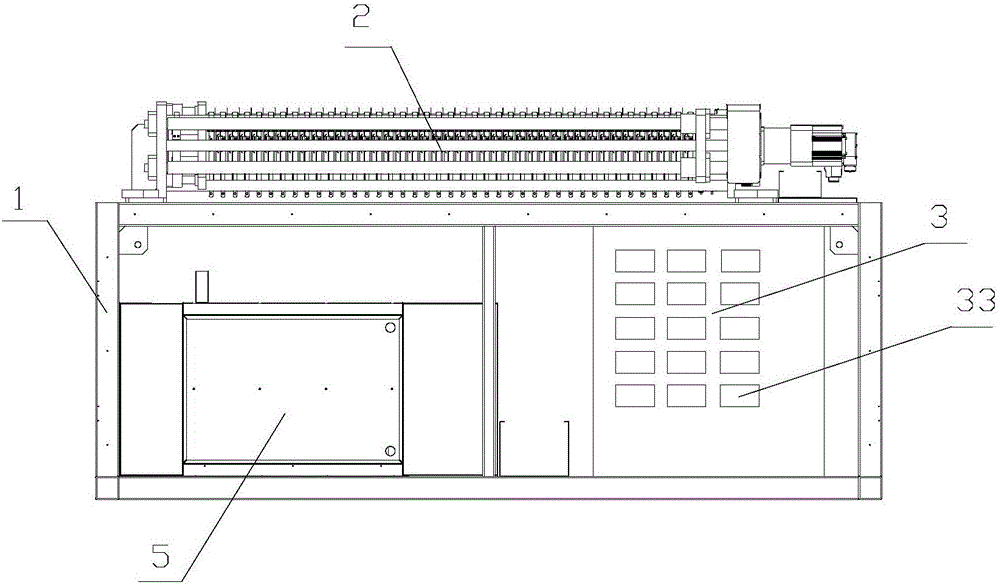

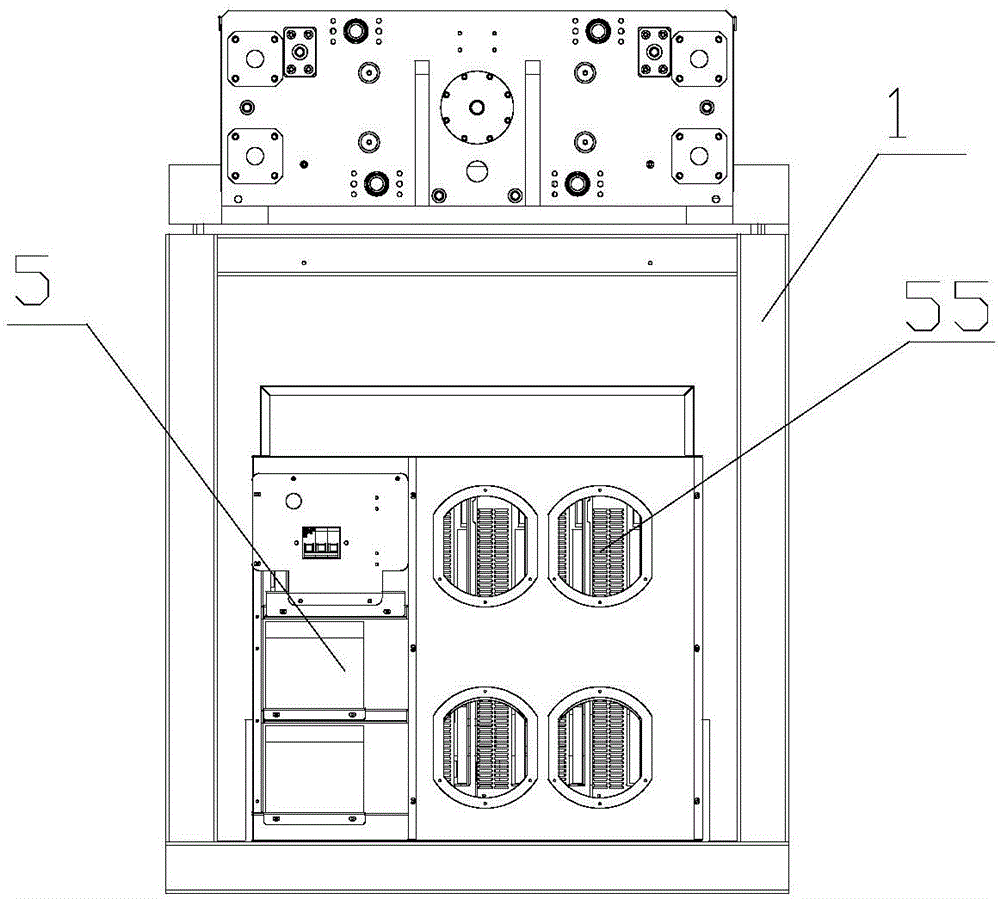

[0045]Embodiment 1 The double-side lug polymer pouch power battery formation fixture machine according to the present invention includes a frame 1, a pressure control assembly 2, a heating control assembly 3, a charging and discharging device 5, and a controller. The pressure control assembly 2. The heating control component 3 and the charging and discharging device 5 are both arranged on the frame 1, and the pressure controlling component 2 and the heating controlling component 33 are both connected to the power supply terminal of the charging and discharging device 5, wherein the The pressure control assembly 2 is arranged on the working table of the frame 1, and the heating control assembly 3 is arranged on the pressure control assembly 2; the control terminal of the pressure control assembly 2, the control terminal of the heating control assembly 3, the charging and discharging The control terminals of the device 5 are respectively electrically connected to the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com