Optical filter testing method and optical filter testing device

An inspection method and inspection device technology, applied in the field of optical filter inspection, can solve the problems of low efficiency, complexity, and increased defective rate of optical filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

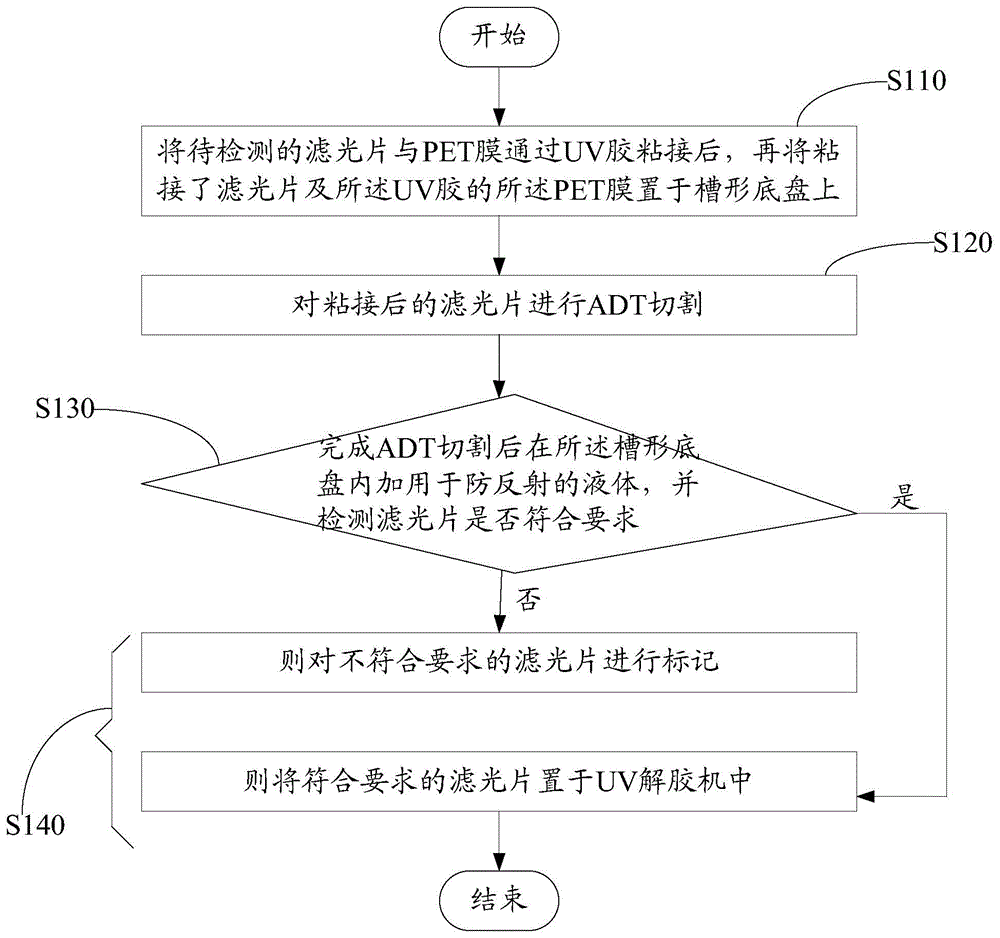

[0026] like figure 1 Shown is the flow chart of the filter inspection method.

[0027] A method for testing an optical filter, comprising the steps of:

[0028] Before the optical filter is bonded, it is also necessary to conduct a routine inspection on the optical filter to be inspected, and the routine inspection is to inspect whether the optical filter has obvious scratches, stains, white spots or chipped edges.

[0029] Visually inspect the appearance of the filter for obvious defects such as scratches, smudges, white spots, or chipped edges. If there is, it will be directly marked as a substandard product. If not, the following tests are performed.

[0030] Step S110, after the optical filter to be detected is bonded to the PET film by UV glue, and then the PET film bonded with the optical filter and the UV glue is placed on a groove-shaped chassis, wherein the PET film The membrane is in contact with the trough pan.

[0031] PET (PolyesterFilm) film is also known as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com