A substation S-type primary flow system and method

A substation and flow-through technology, applied in the direction of measuring electricity, measuring electrical variables, and testing electrical windings, can solve the problems of long flow-through test time, frequent operation of circuit breakers, low test efficiency, etc., to save flow-through test time, Save test time and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

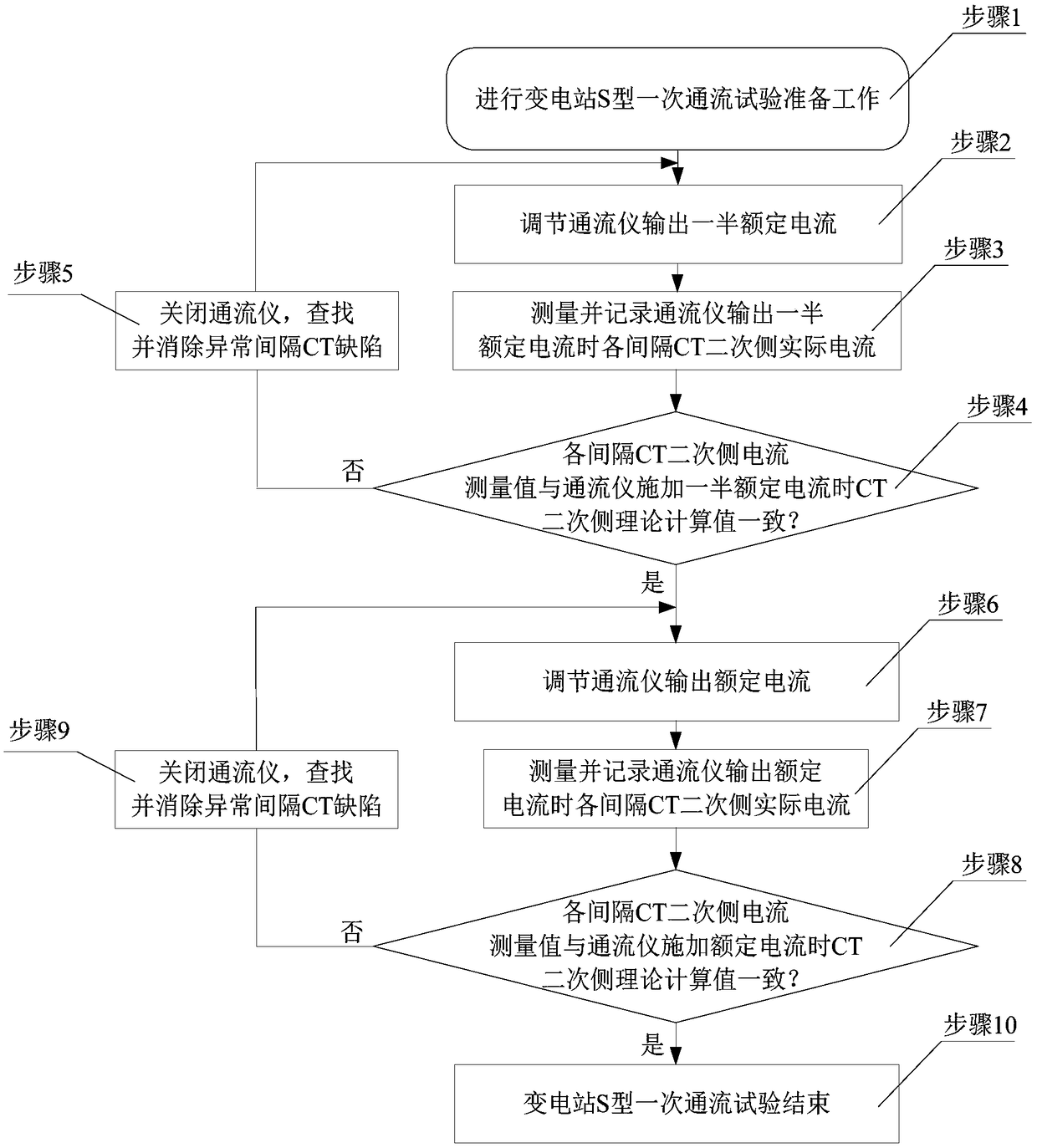

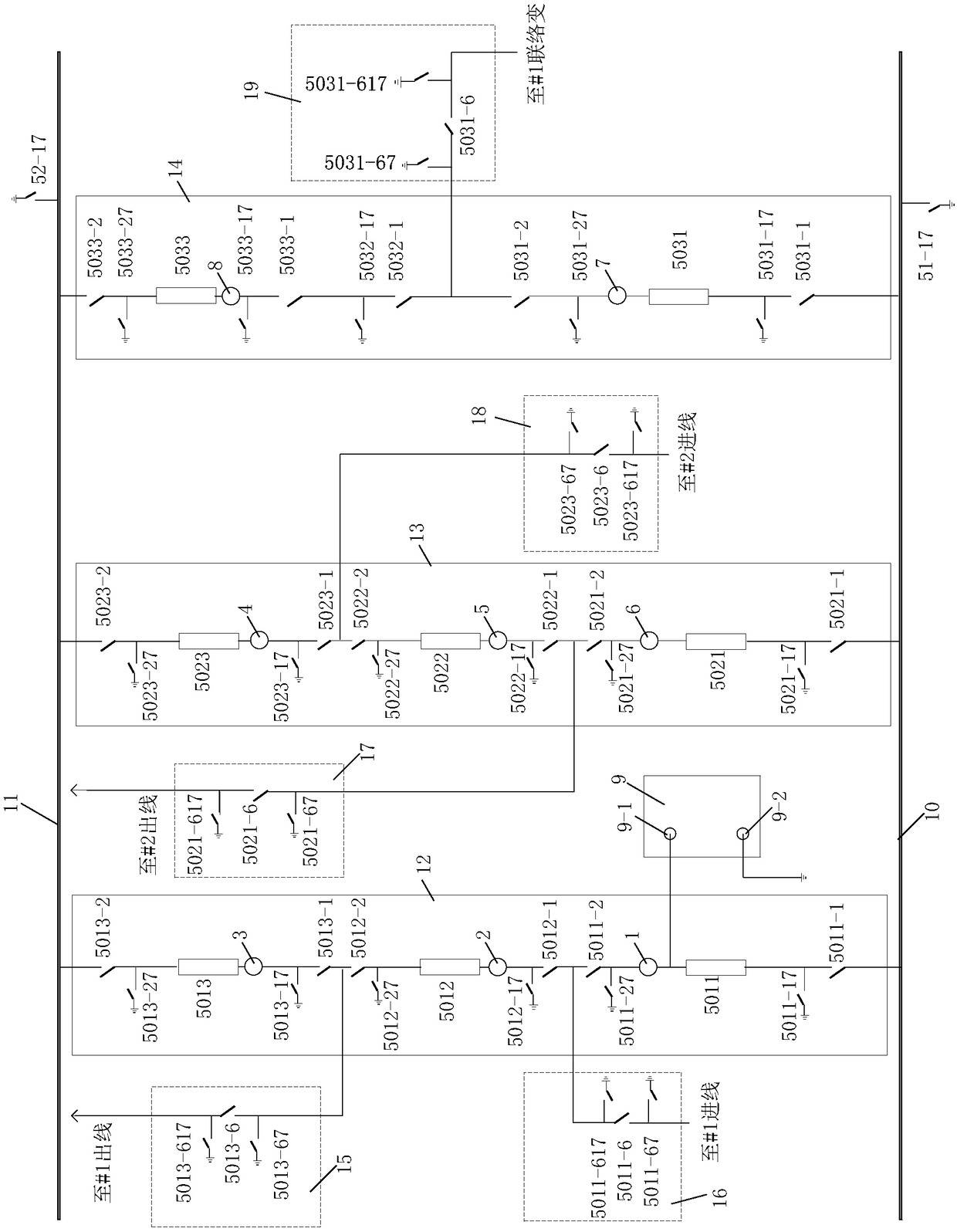

[0042] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0043] Such as figure 1 and figure 2 As shown, a kind of substation S-type primary flow method of the present invention comprises the following steps:

[0044] 1) Carry out the preparatory work for the S-type primary flow test of the substation, and enter step 2) after all the preparatory work is completed;

[0045] 2) Turn on the power supply of the current meter 9, adjust the output of the current meter 9 to half the rated current, and enter step 3);

[0046] 3) Measure and record the actual current on the secondary side of each interval CT when the flow meter 9 outputs half the rated current, and then enter step 4);

[0047] 4) Judging whether the current measurement value of the CT secondary side of each interval is consistent with the theoretical calculation value of the CT secondary side when half the rated c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com