Thermal analysis method for determining content of each phase state ingredient of half crystallization high molecular material

A technology of polymer material and component content, which is applied in the direction of material thermal analysis, analysis material, measuring device, etc., can solve the problem of no further phase state component content and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

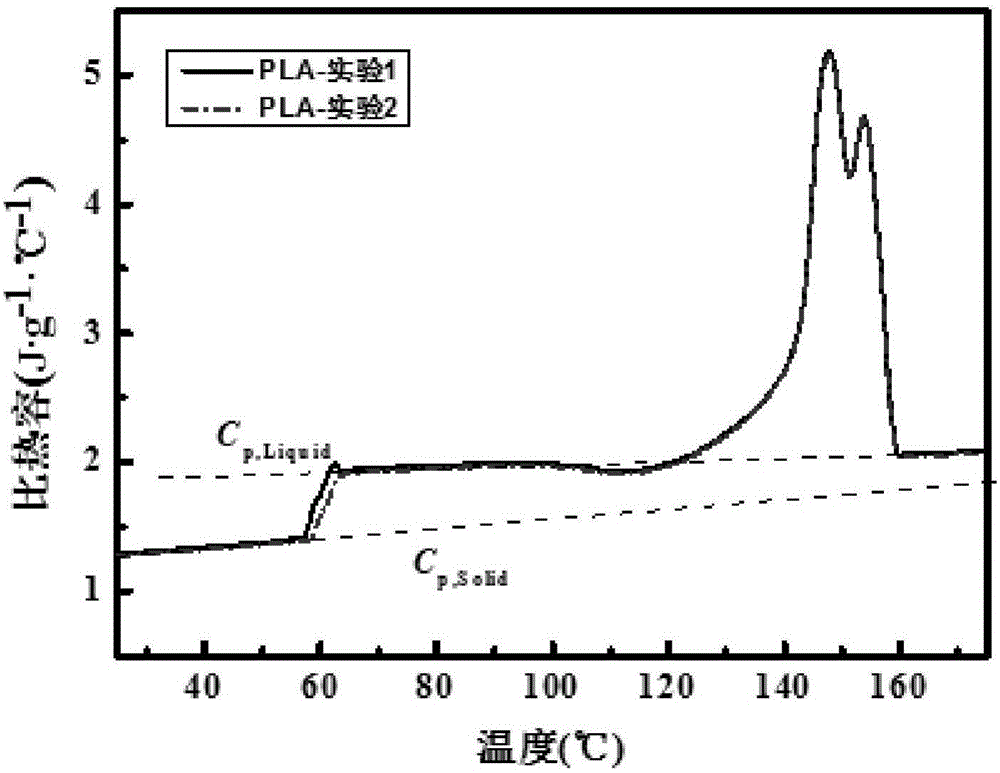

Examples

Embodiment 1

[0033] Embodiment 1: A kind of thermal analysis method of measuring the content of each phase state component of semi-crystalline polymer material, concrete operation is as follows:

[0034] (1) Weigh 40 mg of the standard substance sapphire, put it in an aluminum crucible, cover it with an empty plate and compact it, and carry out StepScan heating at 25-175°C under 15ml / min nitrogen gas, with a heating rate of 5°C / min, every Increase the temperature by 1 °C for 1 min to obtain the SSDSC curve.

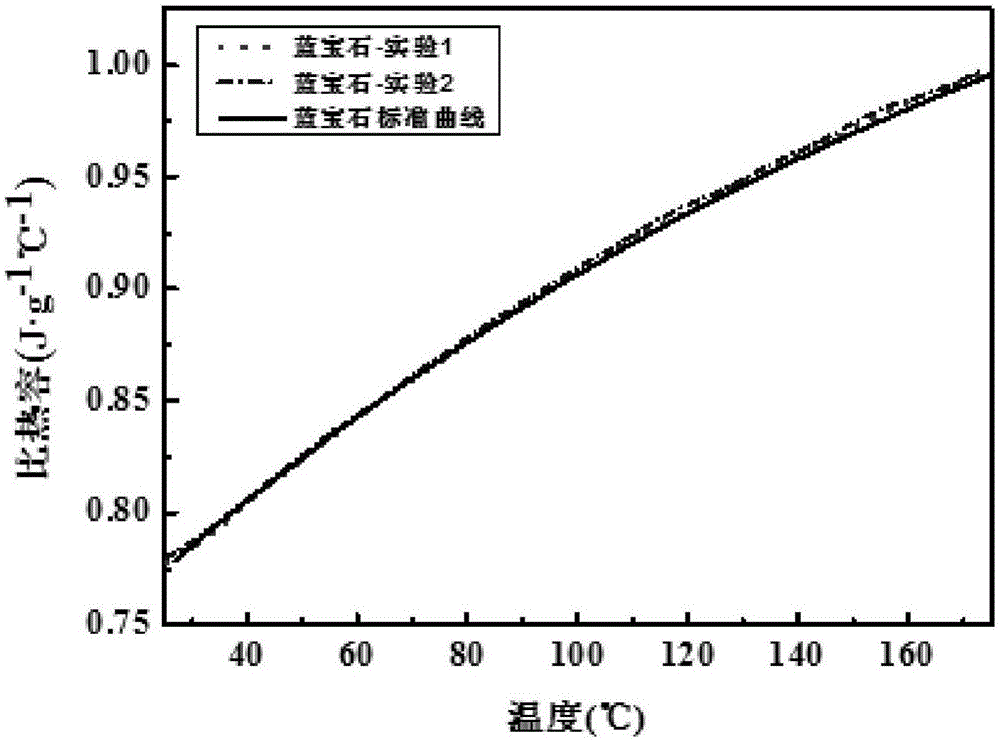

[0035] (2) Through the data analysis of the SSDSC curve, a reversible specific heat capacity curve in the range of 25-175 °C was obtained, and the specific heat capacity value on the experimental curve was compared with the standard specific heat capacity value of sapphire.

[0036] (3) Carry out a SSDSC repeated experiment again according to the method of step (1) and (2), draw a reversible specific heat capacity curve; Standard curve and these two reversible specific heat capacity c...

Embodiment 2

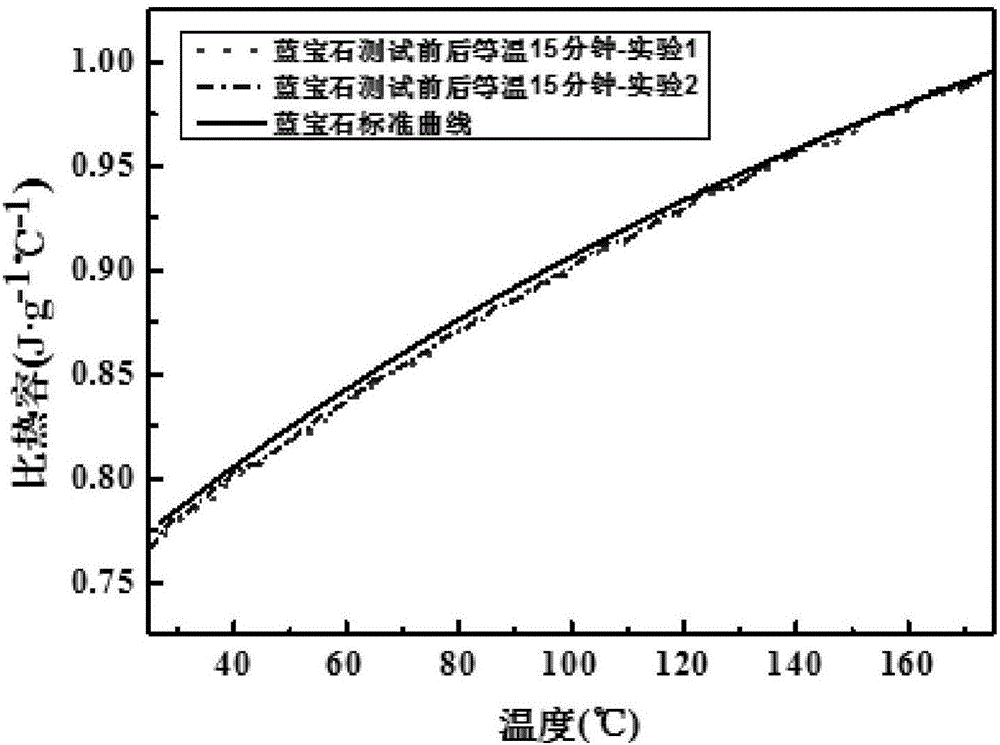

[0048] Example 2: roughly the same as Example 1, the difference is that step (1) when carrying out the StepScan experiment, start to carry out isothermal at 25°C for 15min, and finally at 175°C for another 15min, the standard curve and the obtained two reversible specific heat capacities The curve is plotted at figure 2 middle. Such as figure 2 As shown, the reversible specific heat capacity of sapphire measured by adding isothermal steps before and after the temperature rise in the experiment also has good repeatability and accuracy. The maximum error between the specific heat capacity of sapphire and its standard specific heat capacity during the two repeated tests is 0.8 %, which is less than 2% of the conventional DSC method reported in the literature. And from the experimental results, although the maximum error of embodiment 1 and embodiment 2 is consistent, but in figure 1 When the start and end positions are not isothermal, the specific heat capacity values at l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com