Foaming effect evaluation device and method for chemical agent

An evaluation device and evaluation method technology, which is applied in the direction of measuring devices, scientific instruments, and material analysis through optical means, can solve the problems of high precision requirements such as dosage, large cost impact, and long time consumption, etc., to achieve high precision, Wide range of use, eliminate the effect of blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

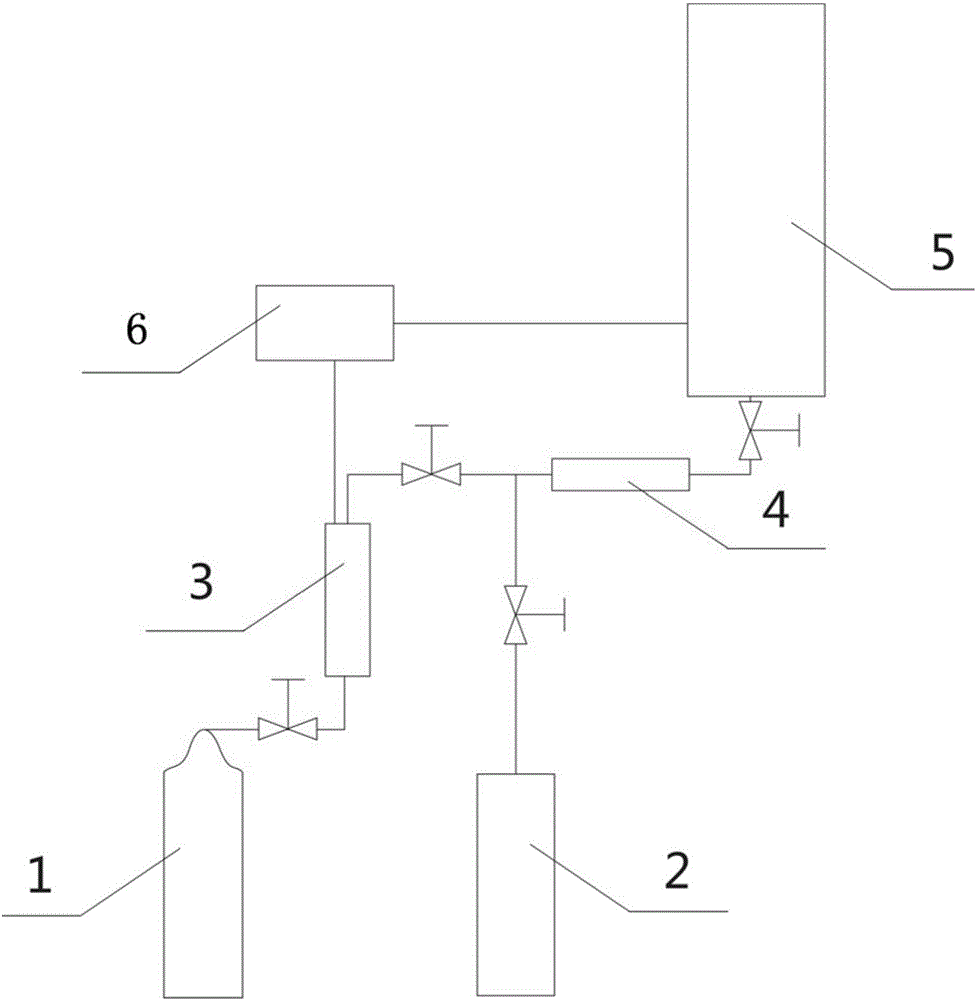

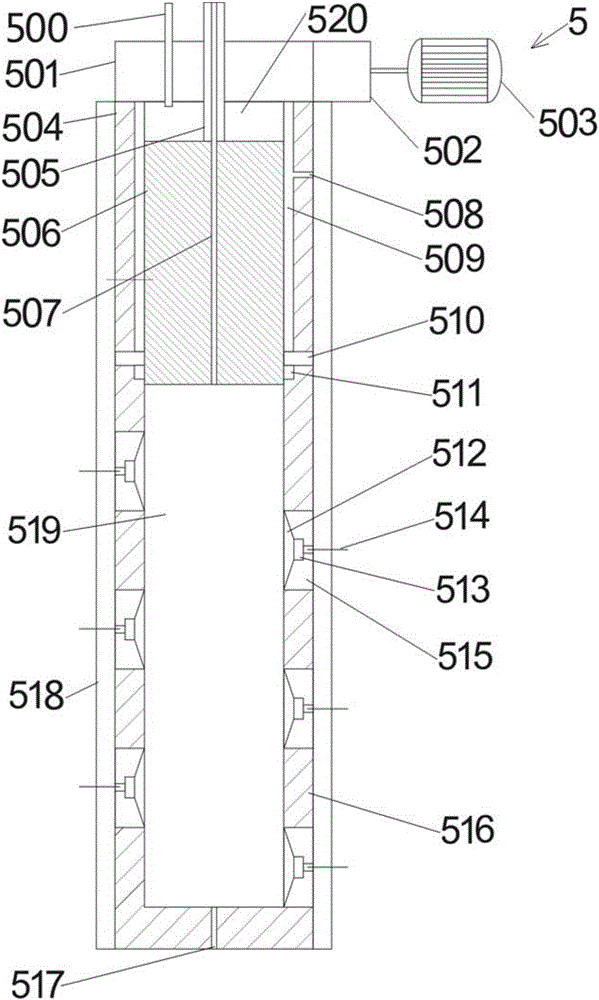

[0036] Such as figure 1 and figure 2 As shown, the present invention provides a kind of chemical agent foaming effect evaluation device, and it comprises: foaming tube 4, and it is provided with inlet end and outlet end, and the inlet end of described foaming tube 4 is connected with gas bottle 1 and foaming tube respectively. The liquid container 2 is connected; the window container 5 is provided with a movable piston 506, a foaming cavity 519 is formed between the piston 506 and the bottom wall of the window container 5, and the bottom wall of the window container 5 is provided with Injection port 517, the foaming cavity 519 communicates with the outlet end of the foaming tube 4 through the injection port 517, and a discharge pipe for vacuumizing the foaming cavity 519 is pierced in the piston 506 507, a plurality of viewing windows corresponding to the foaming cavity 519 are provided on the peripheral wall of the viewing window container 5, and an observation mechanism is...

Embodiment approach 2

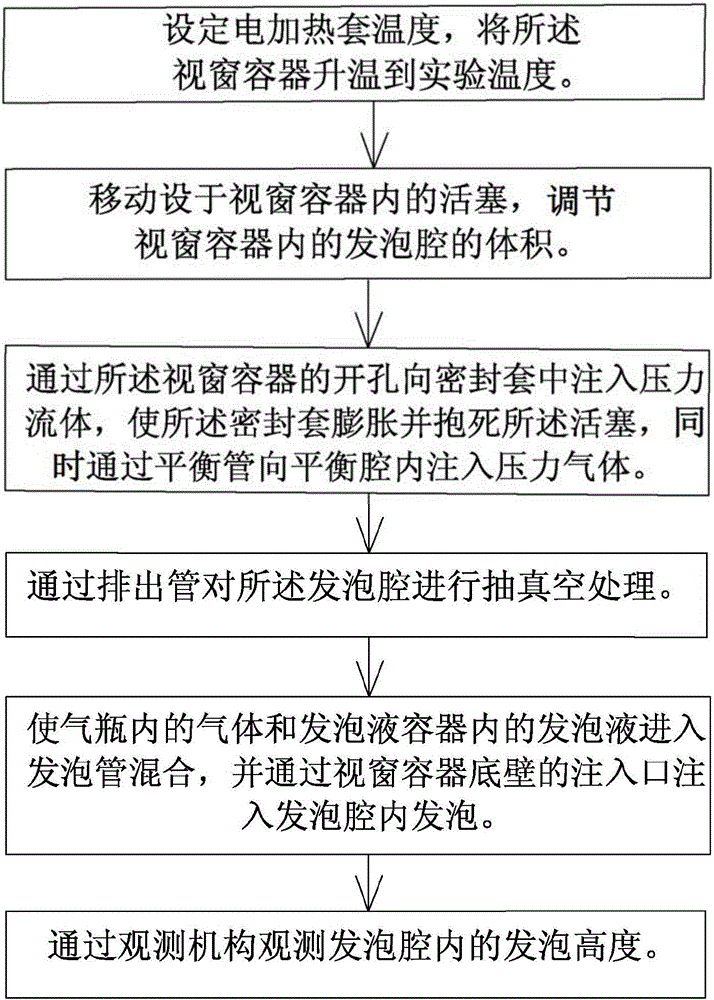

[0050] Such as Figure 1 to Figure 3As shown, the present invention also provides a method for evaluating the foaming effect of a chemical agent, which adopts the above-mentioned device for evaluating the foaming effect of a chemical agent. The bubble effect evaluation method comprises the following steps:

[0051] Step S2, moving the piston 506 arranged in the window container 5 to adjust the volume of the foaming cavity 519 in the window container 5;

[0052] Step S4, vacuumizing the foaming cavity 519 through the discharge pipe 507;

[0053] Step S6, make the gas in the gas cylinder 1 and the foaming liquid in the foaming liquid container 2 enter the foaming tube 4 to mix, and inject foam into the foaming cavity 519 through the injection port 517 of the bottom wall of the window container 5;

[0054] Step S8, observe the foaming height in the foaming chamber 519 through the observation mechanism.

[0055] Specifically, the movement of the piston 506 in the step S2 is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com