A Method for Evaluating the Frost Resistance of Semi-rigid Base Materials Using Dynamic Compressive Resilience Modulus

A compressive resilience modulus, semi-rigid base layer technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the damage to the integrity of the pavement structure, cannot evaluate the pavement strength, and cannot effectively evaluate the semi-rigid base material. Frost resistance and other problems, to achieve the effect of simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

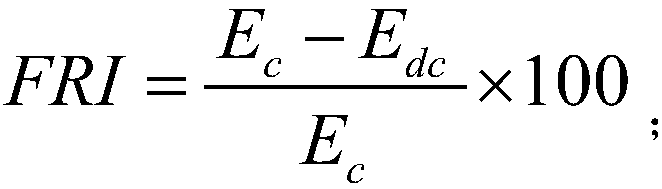

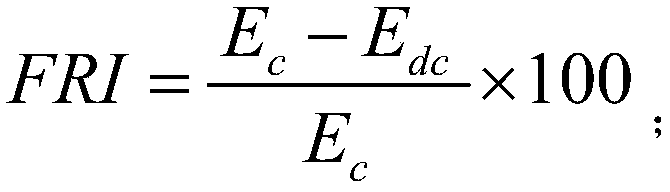

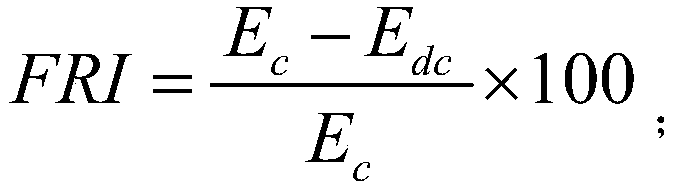

[0045] Specific implementation mode 1: This implementation mode is a method for evaluating the frost resistance of semi-rigid base material by using dynamic compressive resilience modulus, which is specifically completed according to the following steps:

[0046] 1. Determination of the dynamic compressive rebound modulus of the comparison specimen:

[0047] ①. Use the static pressure method or the vibration method to make a cylindrical comparison test piece with a diameter of 150mm and a height of 150mm according to the "Test Regulations for Highway Engineering Inorganic Binder Stable Materials" JTGE51-2009, and then test it at a temperature of 18°C to 22°C and Curing for 90 days at a relative humidity of 95% to obtain a comparison specimen;

[0048] ②. Divide the circumference of the cylindrical section at a distance of 2.5cm from the upper end of the comparison test piece into three equal parts, and then mark the three equal points to obtain three upper marking points; at...

specific Embodiment approach 2

[0084] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the temperature of the low temperature box described in Step 2 ②(2) is -18°C~-18.5°C. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0085] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: step 1. adopts static pressure method or vibration method in accordance with "Highway Engineering Inorganic Binder Stable Material Test Regulations" JTG E51-2009, making A cylindrical comparison test piece with a diameter of 150mm and a height of 150mm was cured for 90 days at a temperature of 20°C and a relative humidity of 95% to obtain a comparison test piece. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com