Prefabricated model pile for model test of soft soil foundation strengthened by electroosmosis combined pile and manufacturing method thereof

A soft soil foundation and model test technology, which is applied in the preparation of test samples, etc., to achieve the effects of saving costs, avoiding steel bar dislocation, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

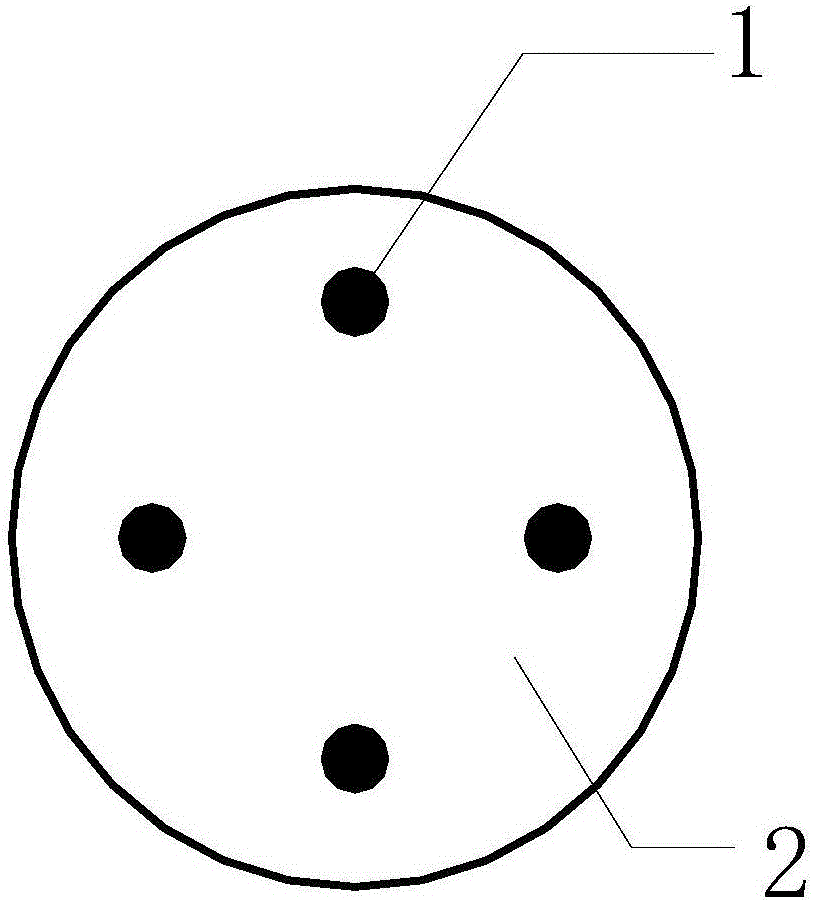

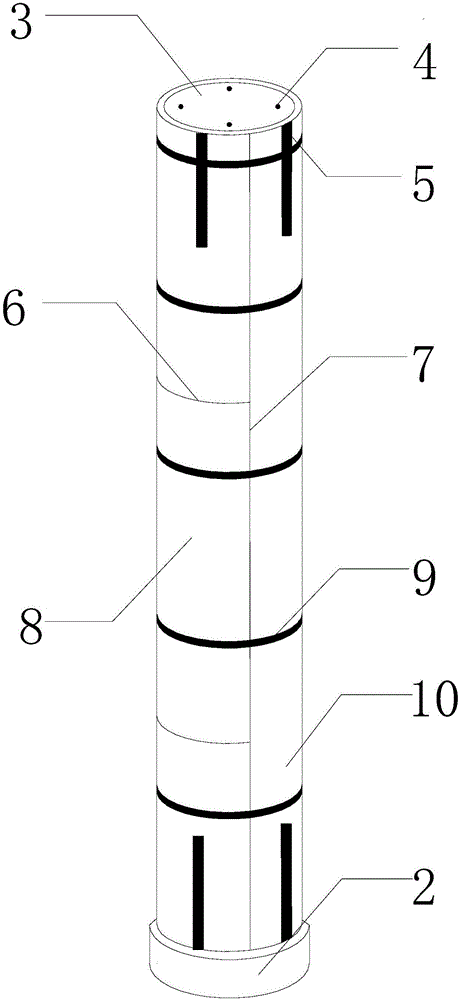

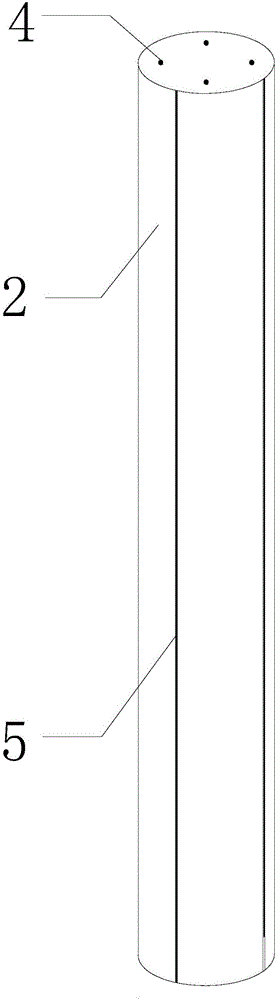

[0018] figure 1 Represented is a schematic diagram after perforating the PVC threaded pipe cap 2 for making a prefabricated model pile 3 for placing 4 steel bars 4 . figure 2 Represented is the final schematic diagram of the prefabricated model pile 3 before demoulding. In the figure, the tops of the first short piece of PVC threaded pipe 8 and the long piece of PVC threaded pipe 10 are tightened with PVC threaded pipe cap 2, and the remaining long pieces of PVC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com