A Calculation Method of Contact Stiffness of Machine Tool-Foundation Interface Considering Concrete Asperity Breakage

A technology of contact stiffness and micro-convexity, which is applied in the field of machine tool dynamics, can solve the problems that the dimensional accuracy cannot be guaranteed, and the role of heavy machine tools is not considered.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

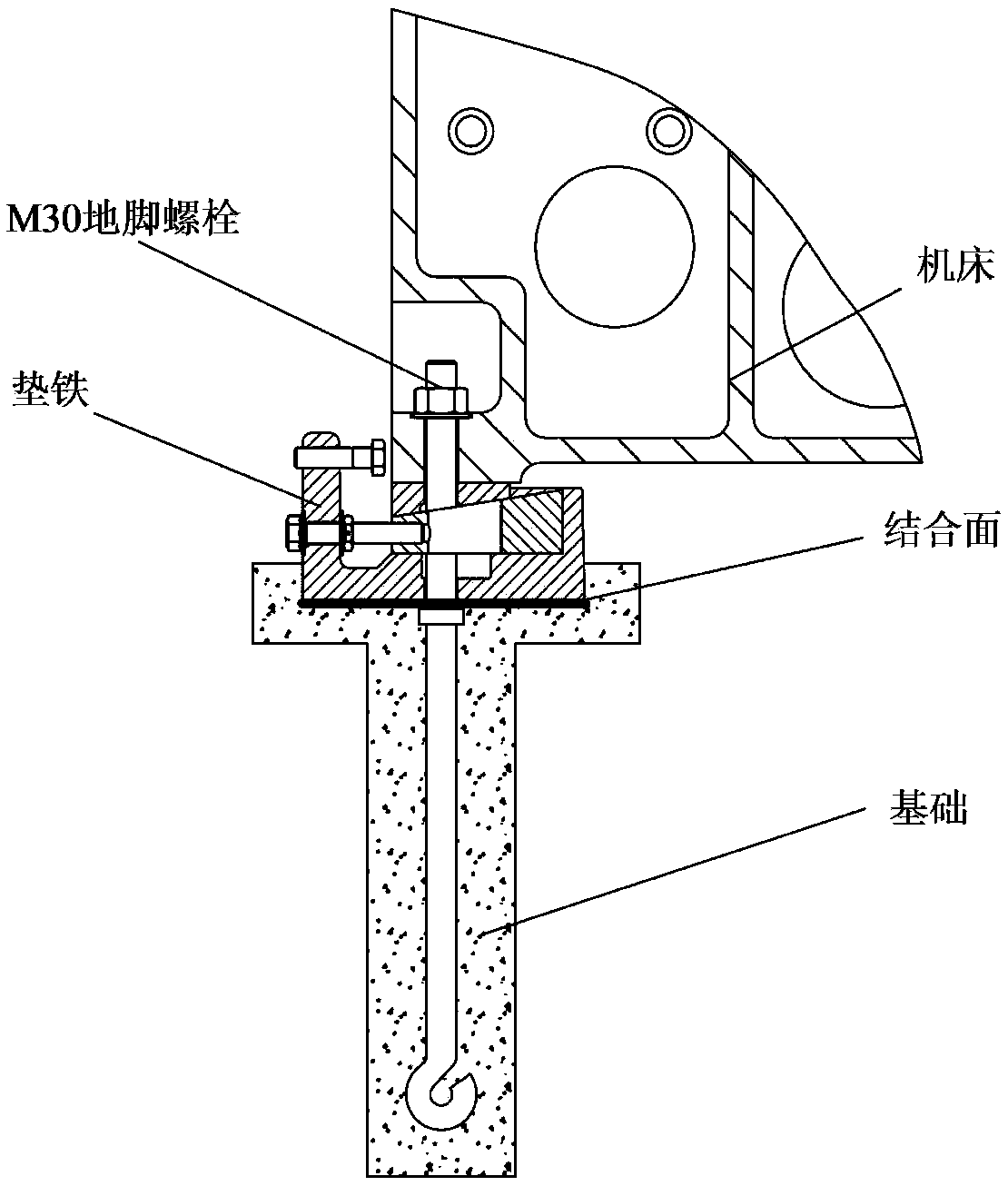

[0014] The present invention implements a method for calculating the contact stiffness of the machine tool-foundation joint surface considering the broken concrete asperity, the following in conjunction with the attached Figure 1-4 , the implementation of the present invention will be described in detail.

[0015] Step (1): Establishment of the critical contact area of a single asperity

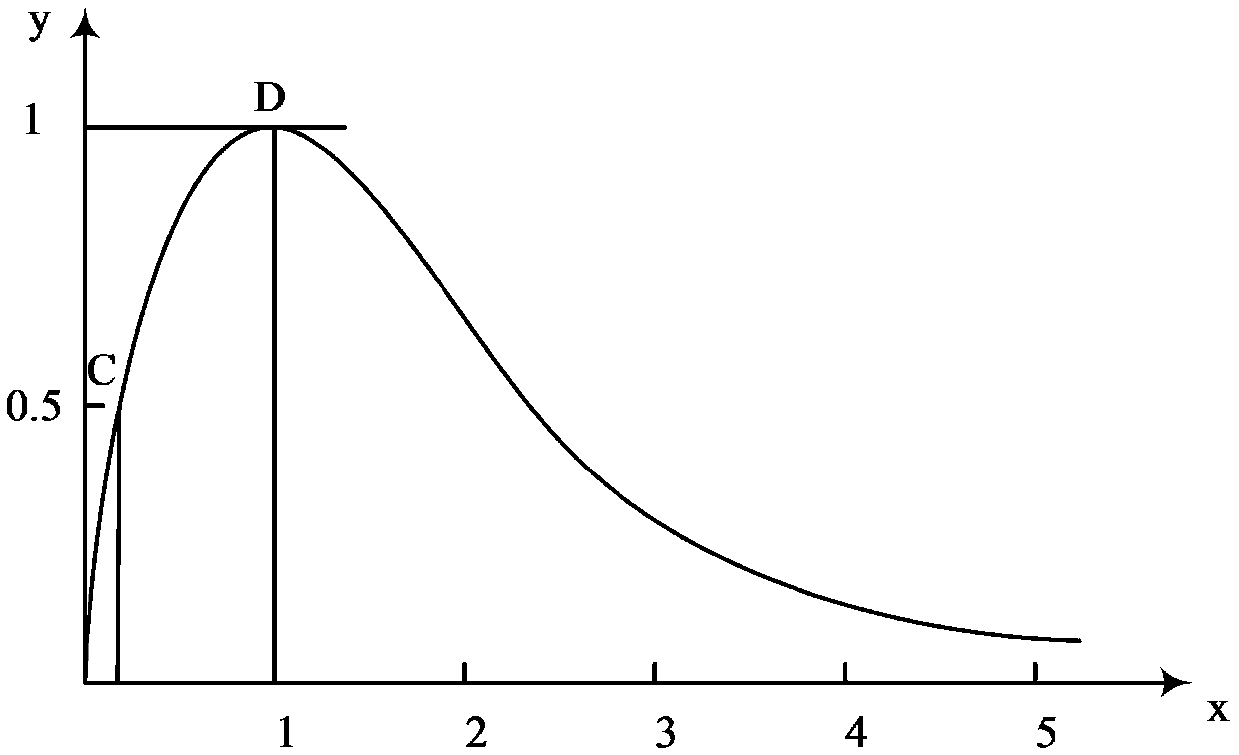

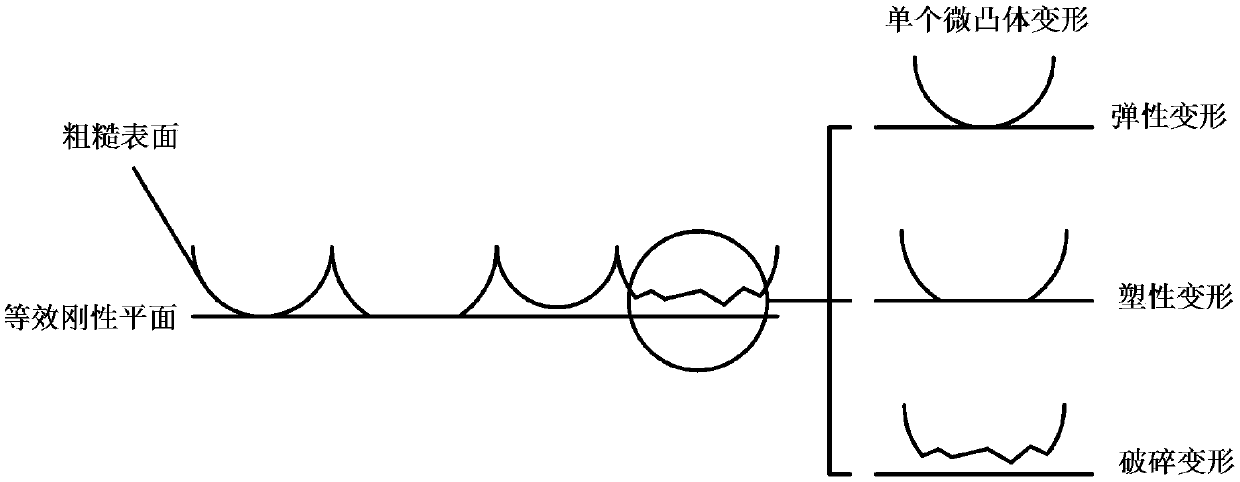

[0016] A large number of experimental conclusions prove that the shape of the stress-strain curve of concrete uniaxial deformation has obvious regular characteristics, such as figure 2 As shown, when the concrete is under uniaxial compression, the asperity in the initial stage shows elastic deformation, and the stress-strain curve is close to a straight line at this stage. The end point of this stage is called the proportional limit, and the corresponding critical stress is σ c , the peak stress value is the compressive strength σ 0 , the proportion limit of ordinary concrete is σ c =(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com