Warning device for accurately measuring liquid level and false liquid level of absorption tower

A technology of false liquid level and alarm device, applied in the direction of buoy liquid level indicator, etc., can solve the problems of sacrificing production efficiency, increasing energy consumption and operating cost of desulfurization system, affecting the operating efficiency of desulfurization system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

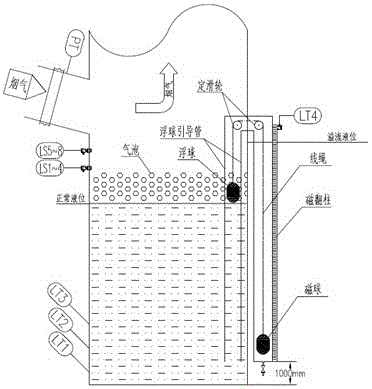

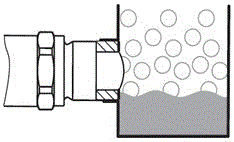

[0013] The invention transforms the traditional magnetic flap liquid level gauge into a split structure, as attached figure 2 As shown, the split type magnetic flap liquid level gauge includes a float, a float guide tube, a fixed pulley, a wire rope, a magnetic ball, a magnetic flip column, and a transmitter. Among them, the guide pipe of the floating ball is specially designed to adapt to the working conditions of the absorption tower, so as to avoid the irregular floating of the floating ball on the liquid level under the action of the flowing slurry, spraying slurry, and spraying water, which will affect the measurement.

[0014] Depend on figure 2 It can be seen that the magnetic flap liquid level gauge is a contact measurement, and the floating ball changes with the change of the liquid level. The whole process of contact measurement has no blind area and false liquid level. The floating ball floats up and down under the action of the buoyancy of the slurry. Under the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com