Method for measuring roundness of large cylinder

A cylinder and roundness technology, applied in the field of cylinder roundness measurement, can solve the problems of low accuracy and reliability, large impact on the installation period of the unit, and long measurement process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

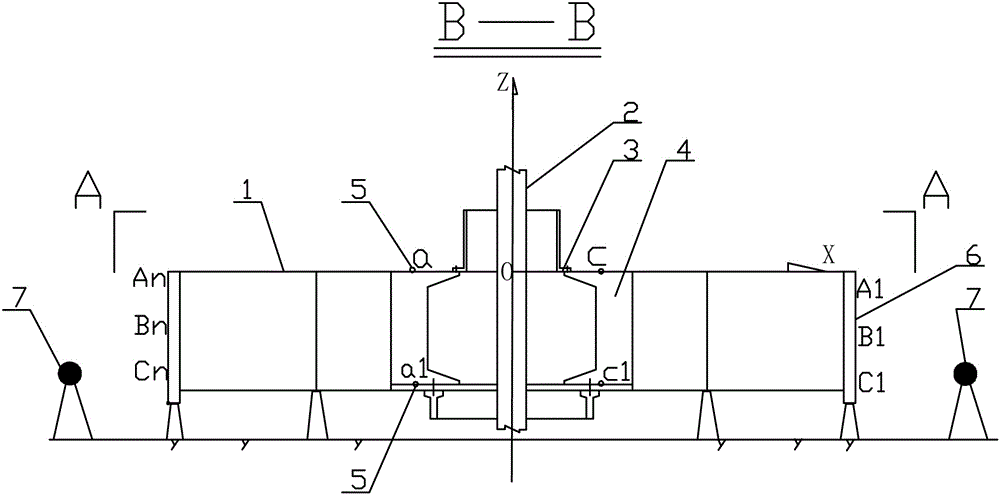

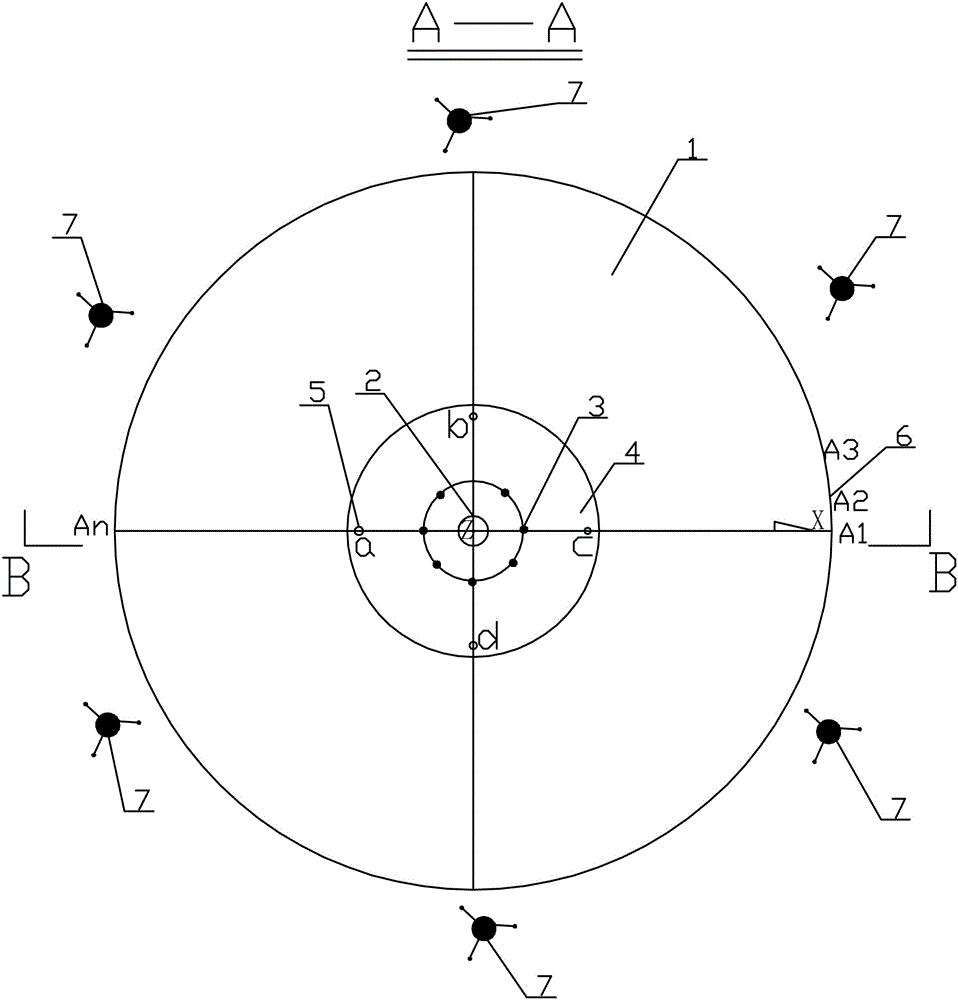

[0025] Such as Figure 1-2 Shown:

[0026] Step 1: When the cylinder 1 is assembled before installation, measure the position of the central axis of the cylinder 1, establish a coordinate system with the central axis of the cylinder as the axis, and use the datum transformation method to calibrate the coordinates of the centerline datum mark point 5 of the cylinder 1 .

[0027] Large cylinders are generally composed of multiple circular components, such as guide bearings, central bodies, shaft connections, external structures, etc. The central axis of the cylinder is the datum of the assembly of the cylinder and the datum of the roundness measurement of the cylinder, and its central position is generally determined by the cylindrical guide bearing. Determining the center line of the cylinder is the premise of this technical solution. During the assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com