Automatic control method and device for aluminum melting furnace system

An automatic control device and aluminum melting furnace technology, applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems of air consumption, fuel waste, low temperature of molten aluminum, etc., and achieve the effect of reducing system waste and flexible supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

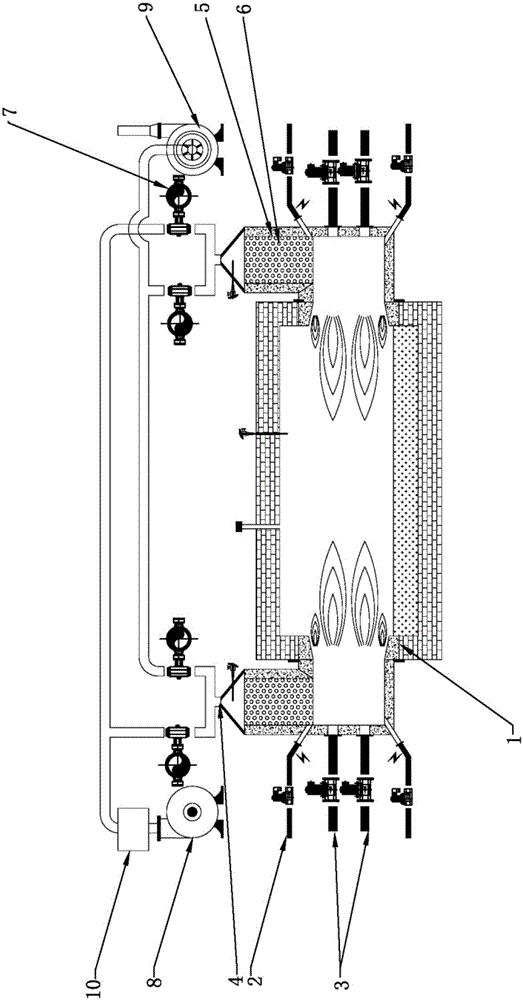

[0021] This embodiment provides an automatic control method for an aluminum melting furnace system. For the convenience of description, this embodiment assumes that this method is applied to such figure 1 The aluminum melting furnace system shown. The system includes a furnace body 1, and the two sides of the furnace body 1 are respectively provided with an ignition nozzle 2 for ignition and an air supply gun 3 for supplying combustible gas. Each side of the furnace body 1 is provided with two air supply guns 3, and the nozzle sizes of the two air supply guns 3 are different. Therefore, controlling the opening and closing of the two air supply guns 3 can realize three different gears. bit combustible gas supply flow. Certainly, according to needs, more air supply guns 3 can also be provided to realize more air supply gears. In addition, it is also po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com