Thread transmission type electronic expansion valve

An electronic expansion valve, transmission type technology, applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of high noise, complicated valve body manufacturing process, easy wear or jamming of magnetic steel sleeve, etc., to reduce friction and Effects of collision noise, simple structure, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

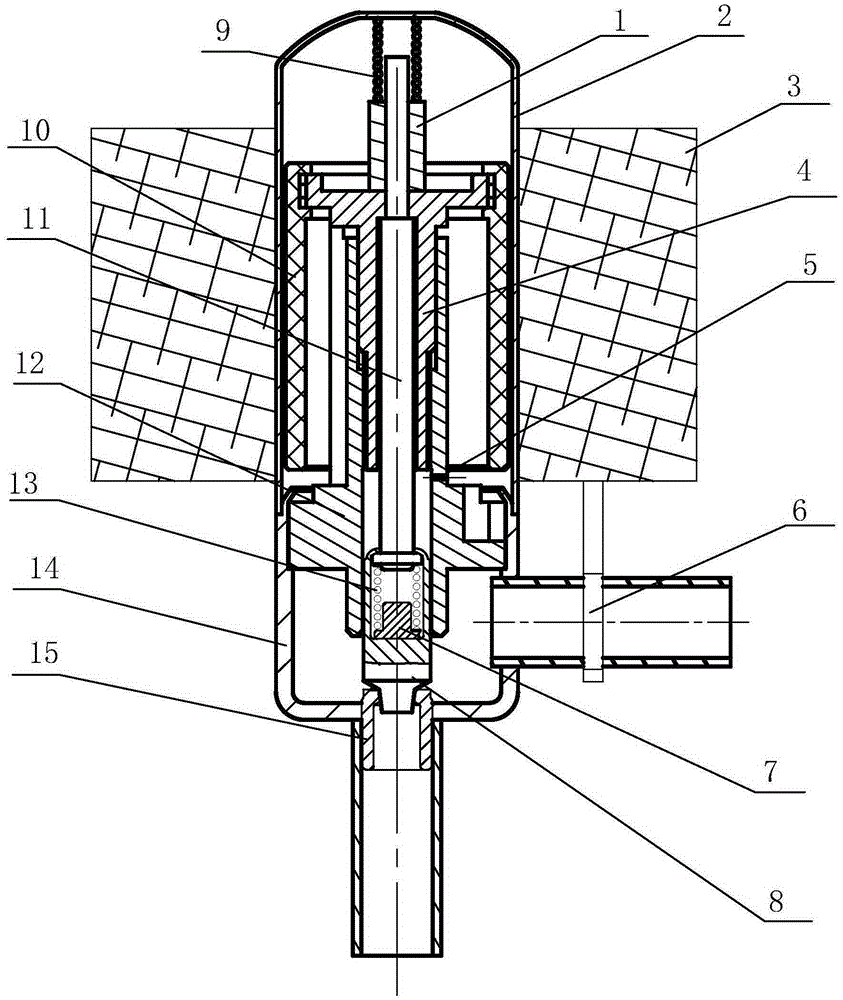

[0016] Such as figure 1 As shown, the present invention includes a valve body, a coil 3 and two medium conveying pipes. The valve body includes a housing and a valve stem part accommodated in the inner chamber of the housing, a nut sleeve 12 and a valve stem driving mechanism. The valve stem driving mechanism includes a magnetic The steel sleeve 10 and the valve stem sleeve 4, the valve stem sleeve 4 is provided with an integrally formed connection plate, the valve stem sleeve 4 is located in the inner cavity of the magnetic steel sleeve and is connected and fixed with the magnetic steel sleeve 10 through the connection plate, the outer shell is composed of an inner The front seat cover 14 with one end open and the rear seat cover 2 are docked, and the outer surface of the front seat cover is provided with a rear-facing step end face shoulder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com