Resonance perforated-plate type electronic control fuel injector with hydraulic feedback function

An electronically controlled fuel injection and fuel injector technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of large dynamic oil return, energy loss, etc., to reduce pressure fluctuations and improve pressure fluctuations , to ensure the normal and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention is described in more detail below in conjunction with accompanying drawing example:

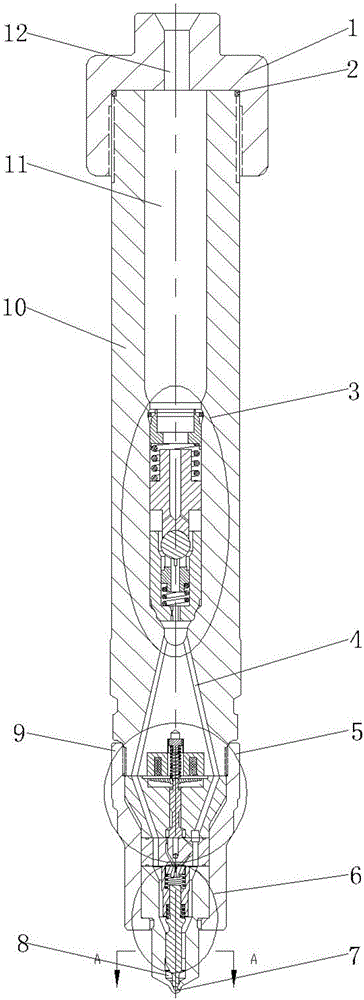

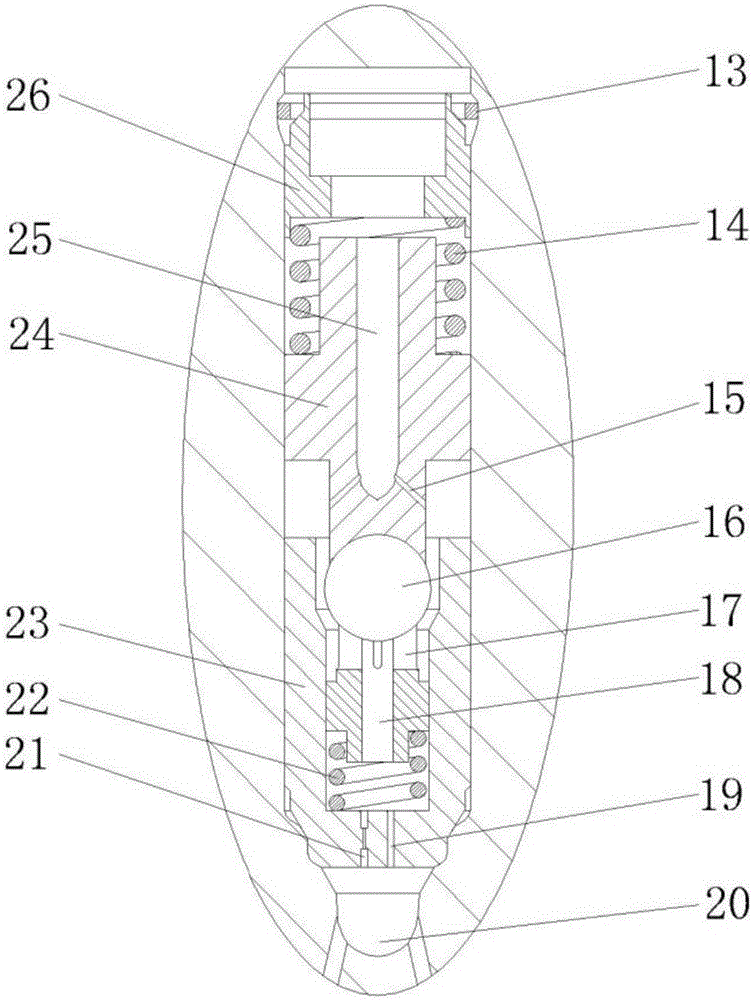

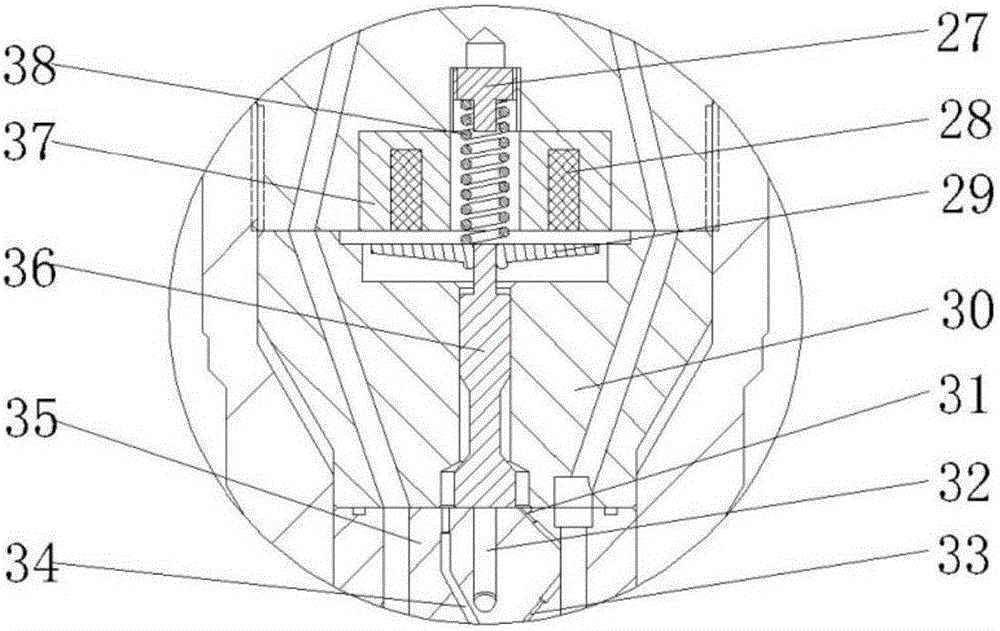

[0022] combine Figure 1-5 , The present invention includes an injector head 1 , a restrictor valve assembly 3 , a solenoid valve assembly 5 , a needle valve assembly 6 , a tight cap 9 , and an injector body 10 . The fuel injector head 1 is mounted on the fuel injector body 10 through threaded fitting connection, and is sealed by the sealing ring 2 placed on the fuel injector body 10 . A main oil inlet hole 12 is arranged in the injector head 1 and communicates with the pressure accumulator chamber 11 in the injector body 10 . A restrictor valve assembly 3 is arranged below the accumulator chamber 11 . The flow limiting valve assembly 3 is installed inside the fuel injector body 10, and its main structure includes a retaining ring 13, a damping spring 14, a ball valve 16, a support control slider 17, a ball valve return spring 22, a ball valve return spring seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com