Numerical control winding pumping unit with sealed steel wire rope

A technology of wire rope and pumping unit, which is applied in the field of sealed wire rope numerical control winch pumping unit, can solve the problems of wire rope damage and sealing, and achieve the effects of easy installation and maintenance, reduced wear and downward resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

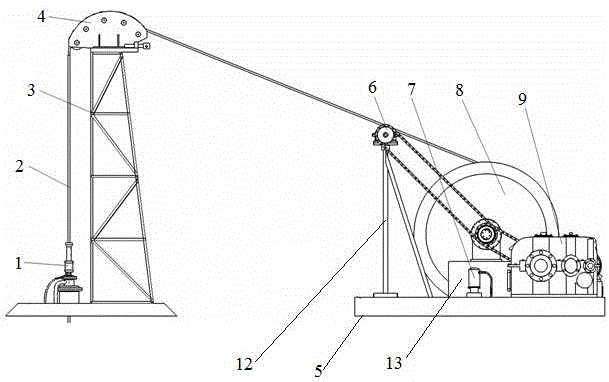

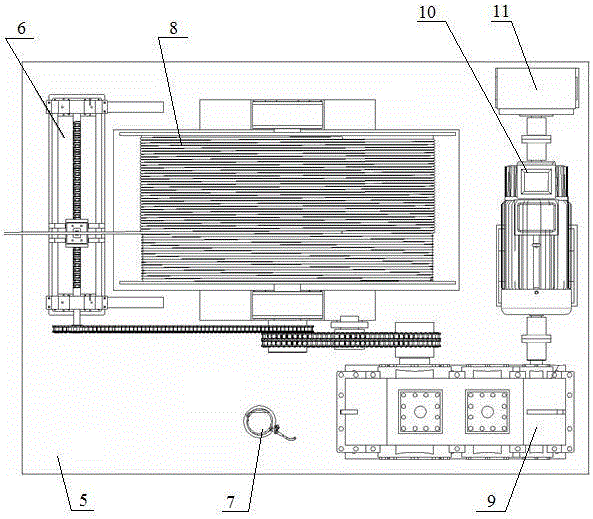

[0015] The present invention will be further explained below in conjunction with the drawings:

[0016] Combine figure 1 , figure 2 As shown, the sealed steel wire rope numerical control winch pumping unit includes a sealed steel wire rope 2, a wellhead bracket 3, a guide mechanism 4, a base 5, a rope arranging device 6, a gas storage tank 7, a reel 8, a reduction box 9, a motor 10, Magnetic powder brake 11, base 5 is equipped with reel 8, gas storage tank 7, reduction box 9, motor 10, magnetic powder brake 11, rope arranging bracket 12, which constitutes the main engine of the pumping unit; magnetic powder brake 11 is connected to the motor through a coupling 10 is connected, the motor 10 is connected to the input shaft of the reduction box 9 through a coupling, the reel 8 is fixed on the barrel base 13, and the output shaft of the reduction box 9 is connected to the shaft of the reel 8 through the first chain inclined upward, and the reduction box 9 An encoder is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com