Downhole torque self-balance cable drilling tool system

A self-balancing, drilling tool technology, applied in the wellbore driving device, drill pipe, drill pipe, etc., can solve the problem of short coiled tubing life, strengthen real-time monitoring and control, get rid of depth dependence, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

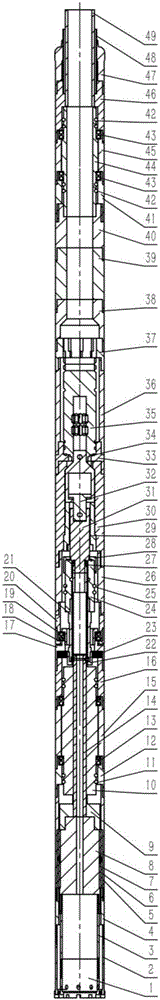

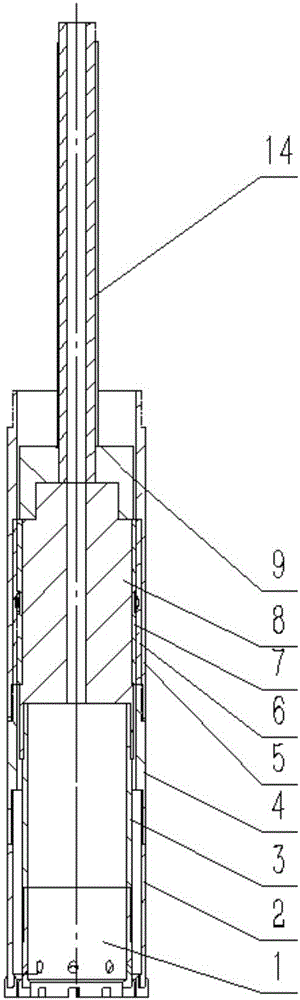

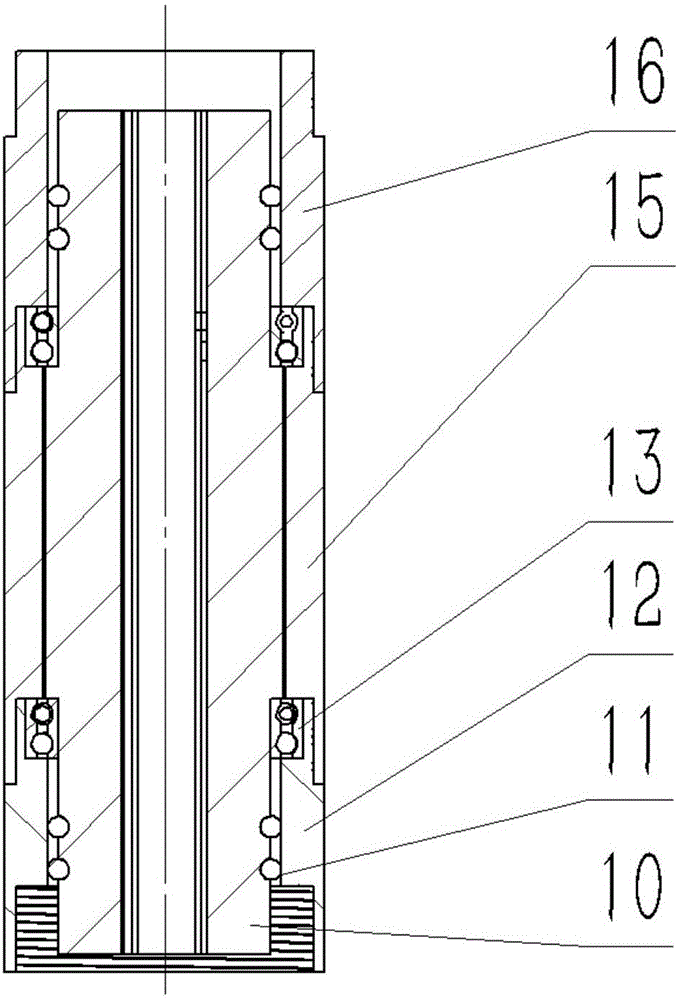

[0025] See Figure 1 to Figure 6 As shown, the present invention proposes a downhole torque self-balancing cable drilling tool system. The drilling tool system is composed of internal and external bit components, power components, internal and external bit pressure adjustment systems, mud circulation systems and jam release systems. The upper drilling tool of the cable drilling tool system only bears the axial force, and the lower drilling tool is reversely rotated by the inner and outer drill bits to achieve torque balance. figure 2 The shown inner and outer drill bit assembly is used for reverse rotation cutting rock, and the surrounding rock is required to provide a small anti-torque moment to the rock in contact with the drill bit, so only a small disturbance to the surrounding rock is generated. Even when drilling in a broken formation, the well wall 50 It is also relatively regular and stable. The inner and outer drill bit assembly includes inner drill bit 1, outer drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com