Ground L-shaped gas extraction drill hole

A gas extraction and ground technology, which is applied in gas discharge, fluid extraction, directional drilling, etc., can solve the problems of poor extraction effect, high cost, and many holes, so as to improve gas extraction efficiency and drill hole positioning accuracy. , the effect of fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

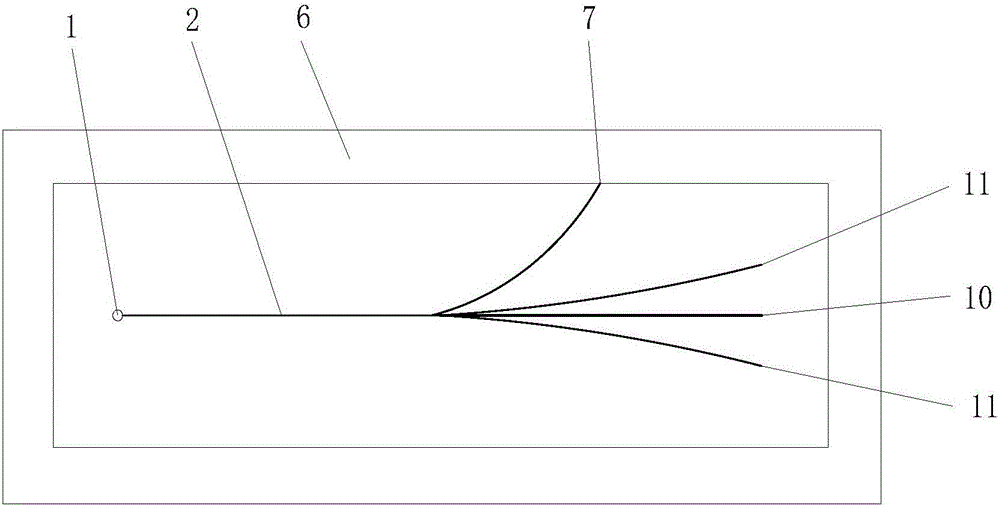

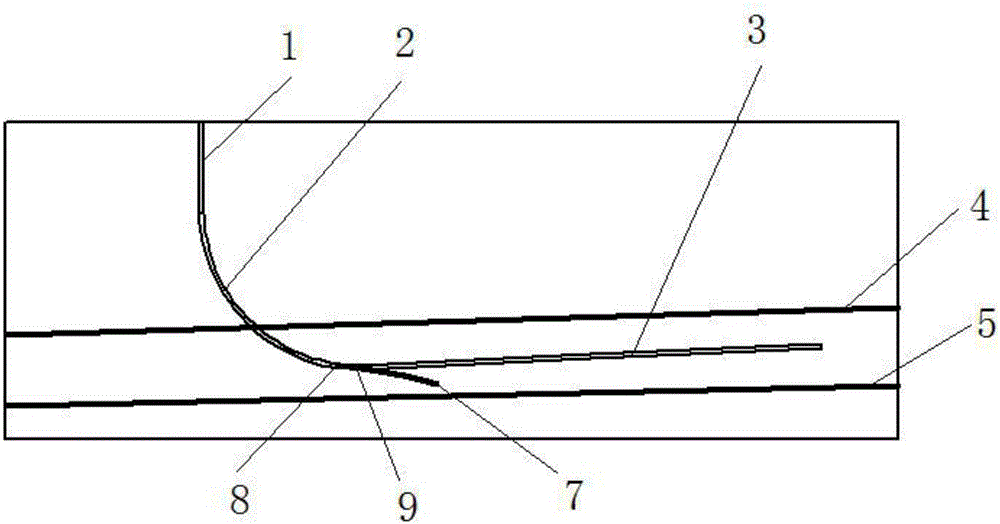

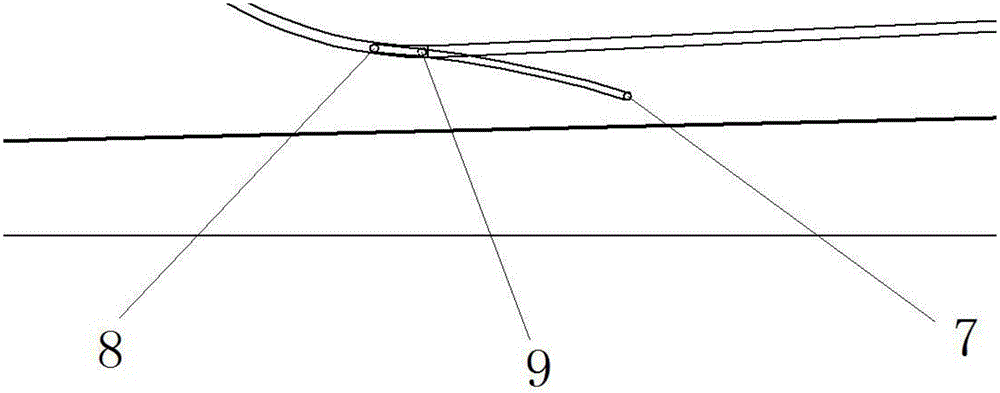

[0017] figure 1 The specific embodiment of the present invention is shown: a ground L-shaped gas drainage borehole, the borehole includes a straight hole section 1, a directional deflection section 2 and an upward section 3, and the straight hole section 1 extends underground to the upper coal seam 4 , the upward section 3 is set in the water-conducting fracture zone of the coal seam roof, the directional deflection section 2 connects the straight hole section 1 and the upward section 3; the straight hole section 1 and the directional deflection section 2 are both lowered into the oil casing, and the upward Section 3 is lowered into the screen pipe as an effective gas drainage section. Upward section 3 includes a main hole 10, and the side wall of the main hole 10 is provided with branch hole sidetracking points 9. There are multiple branch holes 11, the lowest part of the main hole 10 is provided with a drain hole 7 communicating with the underground roadway 6, and the orific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com